Production process and device for friction disc assembly of elevator brake

A technology of elevator brakes and production technology, which is applied in the direction of manufacturing tools, grinding devices, grinding/polishing safety devices, etc., which can solve the problems of weak braking force of brakes, low flatness of friction surfaces, and inclined placement of friction plates, etc. The effect of reducing production costs, increasing grinding speed, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

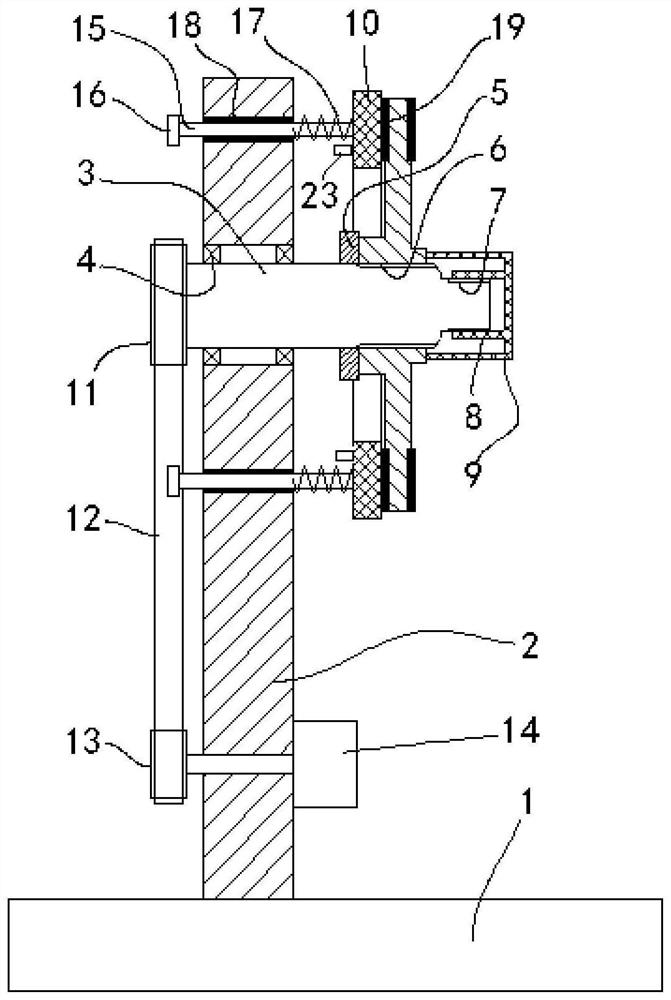

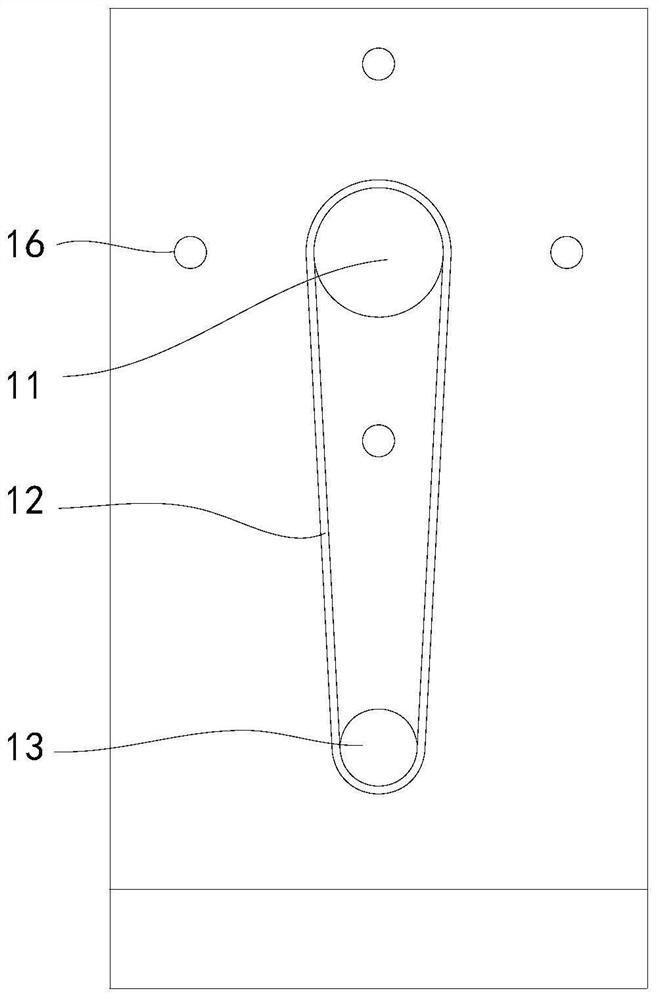

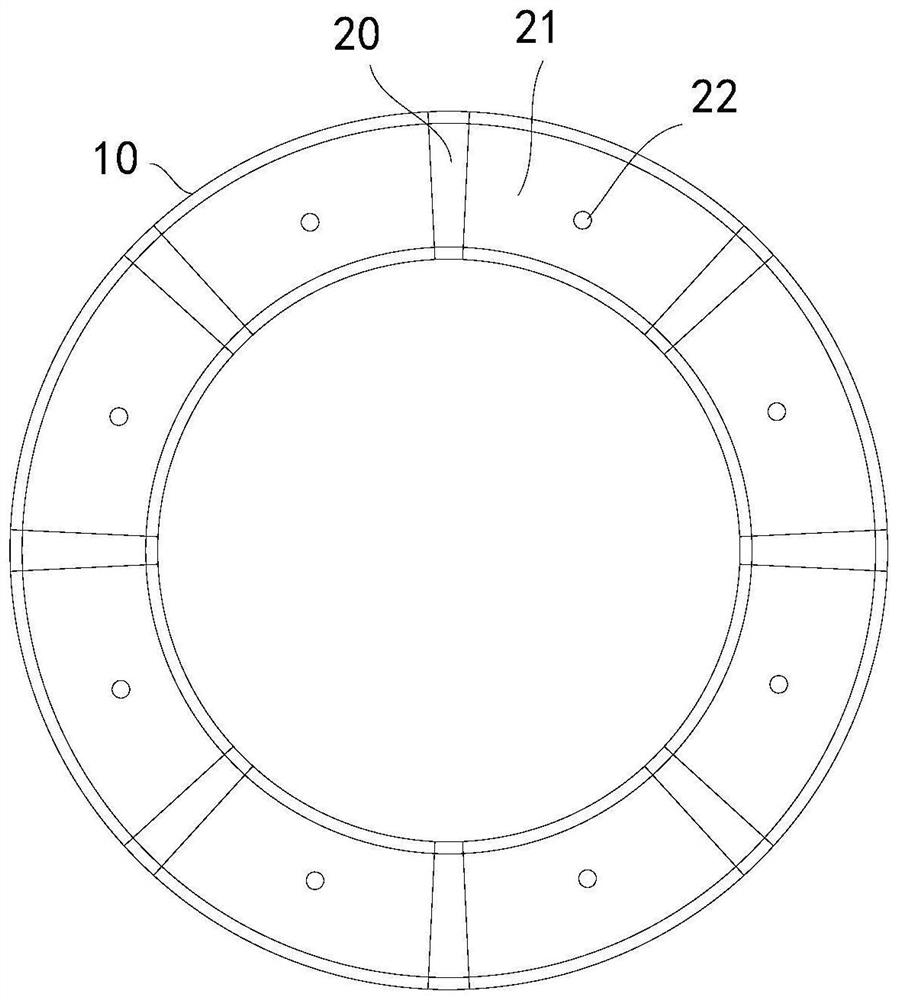

[0022] Example. The production device of the elevator brake friction disc assembly includes a bottom plate 1, a vertical plate 2 is arranged on the bottom plate 1, a horizontal rotating shaft 3 is arranged on the vertical plate 2, the rotating shaft 3 is connected to the vertical plate 2 through a deep groove ball bearing 4, and the vertical plate 2 is arranged on the rotating shaft 3. A drive mechanism is provided, a limit ring 5 is provided on the rotating shaft 3, and the side of the limit ring 5 away from the deep groove ball bearing 4 is provided with a spline part 6 and a thread part 7 in turn, and the diameter of the thread part 7 is smaller than the spline part 6, The rotating shaft 3 is connected to the threaded part 7 through the spline part 6. The threaded part 7 is provided with a screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com