Copper-nickel slag treating method

A processing method and slag technology, applied in the field of copper and nickel pyrometallurgy, can solve the problems of shortening the processing time of converter slag, clogging of smelting production line, small contact opportunity, etc., achieving uniform reduction and sulfidation reaction, avoiding high temperature of slag surface, and speeding up production effect of rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

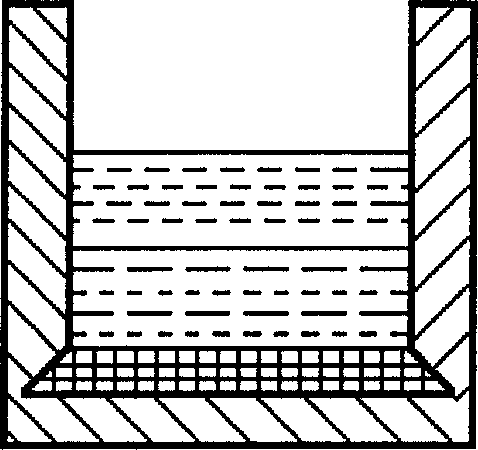

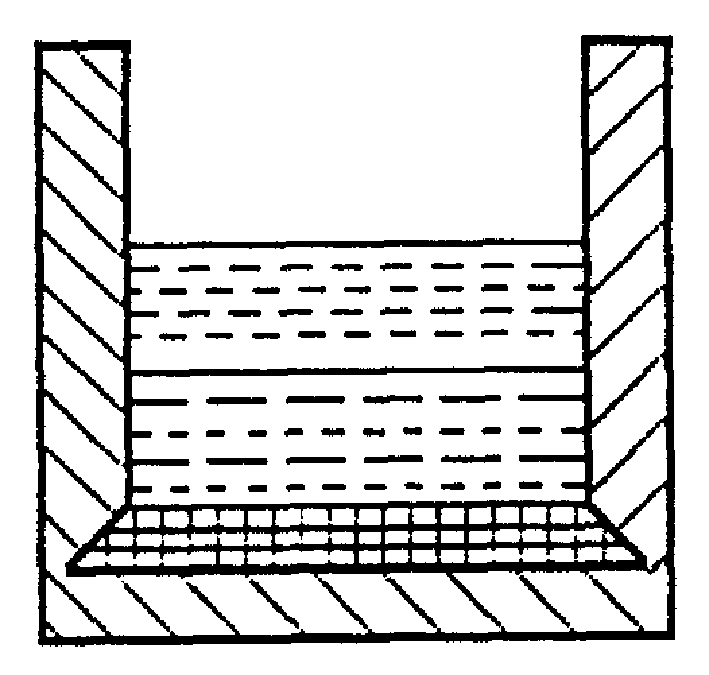

[0051] A small slag washing furnace with an inner diameter of φ500cm and a height of 120cm is selected. The furnace lining and bottom are made of industrial refractory magnesia-chrome bricks. Inverted cone with big bottom and small top, taper about 20°, see attached figure 1 , After the furnace lining is finished, dry it. Then lay a layer of graphite bricks on the bottom of the furnace. The thickness of the graphite bricks is 10cm. Grooves and tenons are respectively processed in the middle of the sides, and they are embedded firmly with each other to prevent the graphite blocks from floating up during slag washing. Finally, fill the gap between the furnace wall and the graphite layer with refractory mud, tamp it firmly, and bake it to dry. When using it for the first time, preheat the cold furnace to about 1000°C with a flame spray gun, and then inject a layer of 10cm thick low-grade matte (Fe38.6%, S26.5%) on the bottom of the furnace. The matte temperature is 1250°C, and t...

Embodiment 2

[0053] The slag washing furnace is the same as in Example 1, but the bottom carbon is changed to metallurgical coke, and the coke particle size is about 3-6mm. After mixing evenly with an appropriate amount of refractory mud, spread it on the bottom of the slag washing furnace, and then vibrate it According to the method, the carbon layer is fully compacted and firm, the carbon layer is 15cm thick, dried, and after preheating, inject pre-melted pyrite (FeS, containing Fe60.0%) matte temperature 1210 ℃, matte layer thickness 40cm, and then Inject electric furnace slag 20cm, slag temperature 1300℃. The content of precious metals in the slag is Co0.15%, Ni, 0.46%, Cu 0.42% and an appropriate amount of flux materials. After feeding, the operation is the same as in Example 1. The total process parameters are furnace temperature 1300 ° C, and self-boiling slag washing for 25 minutes , and finally inject the washed slag into the intermediate insulation bag for precipitation for 60 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com