Device and method for preparing aluminum-based nano material

A nano-material, aluminum-based technology, used in metal extrusion control equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high maintenance cost, high production cost, complicated operation, etc., to achieve high material utilization, improve Mechanical properties, high finish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

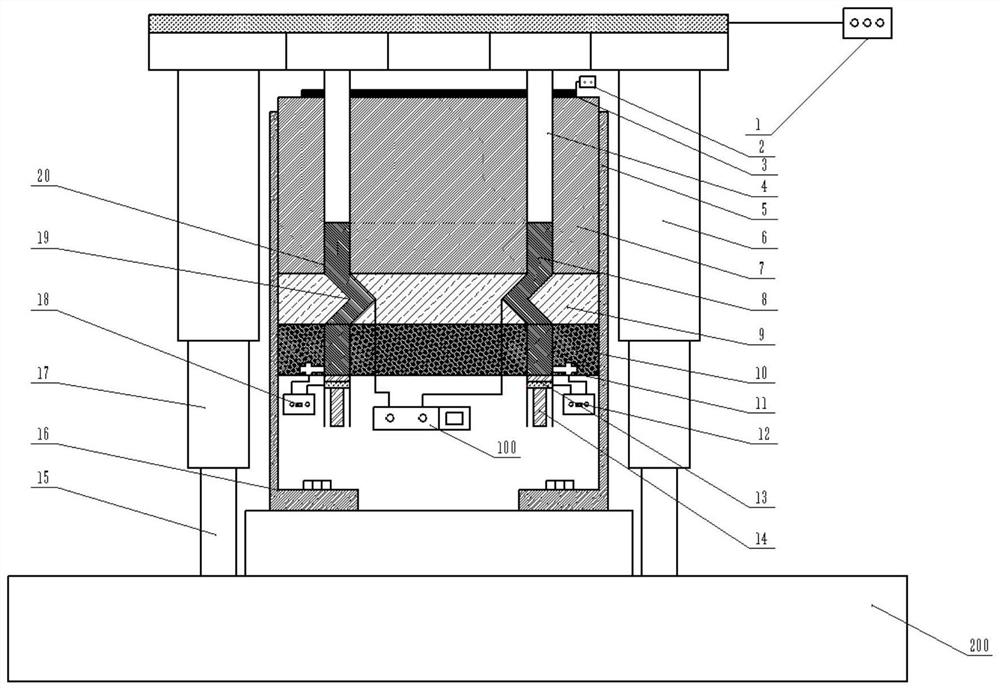

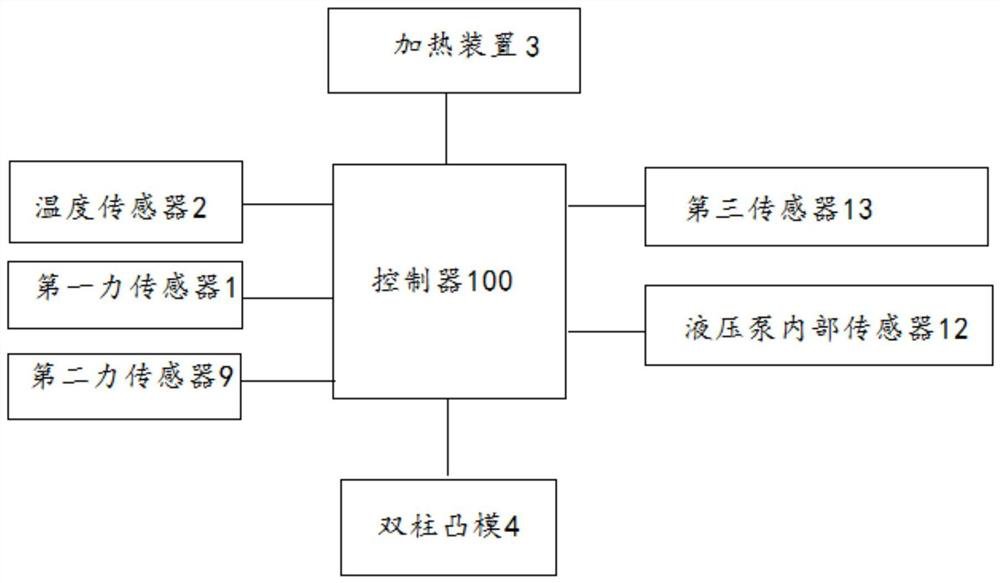

Method used

Image

Examples

specific Embodiment

[0112] In this example, the 6061 aluminum matrix composite material is used as the blank, and the cylindrical blank is prepared. The diameter of the blank is 200 mm, and the length of the blank is 1200 mm. The temperature is 690~730℃, the cooling rate is 1.4~1.6℃ / min, the maximum tensile strength σ of 6061 aluminum base billet max = 240MPa, the compression amount ε is set to 21.2%, the holding time t = 6min=, that is, 360s. During extrusion, lubricating oil needs to be added into the extrusion channel. In this embodiment, the lubricant is 70% to 80% of No. 72 gasoline plus 20% to 30% of graphite.

[0113] The relevant parameters in this embodiment are shown in Table 1 below:

[0114] Table 1 6061 aluminum base billet extrusion process parameters

[0115]

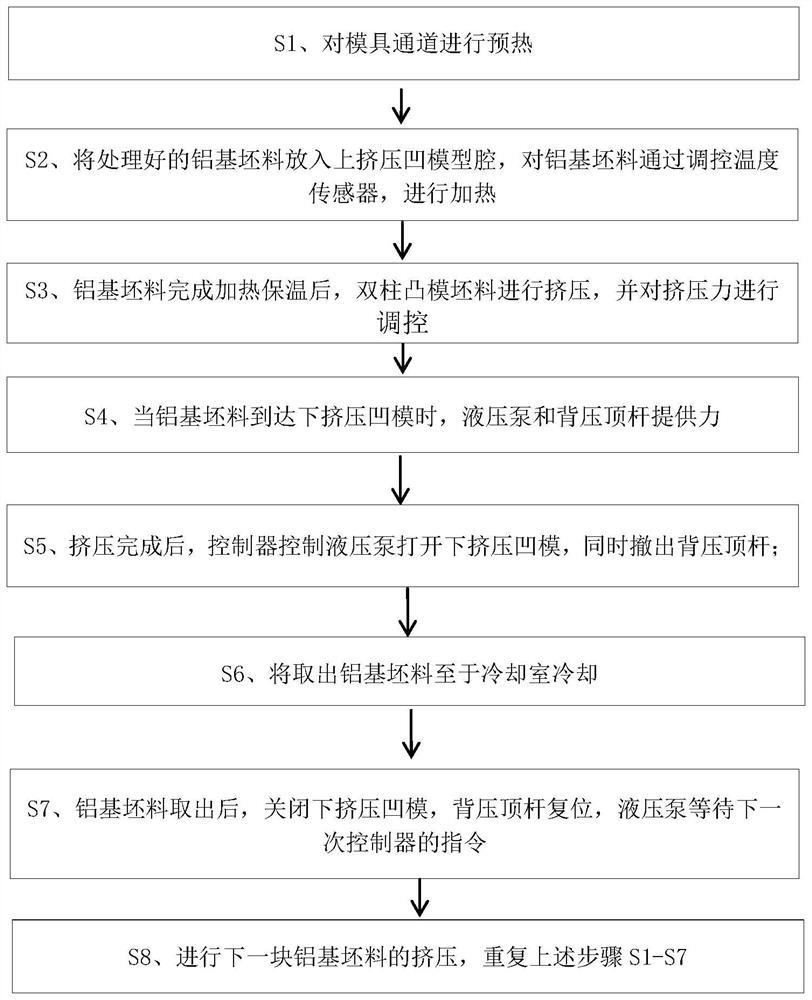

[0116] The extrusion process specifically includes the following steps:

[0117] S1. Preheat the mold channel, the preheating temperature is T 预 is 450℃, and the heat transfer coefficient a is 1500W / (m 2 .°C);

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com