Spinning solution, heat-resistant creep-resistant fiber and preparation method of heat-resistant creep-resistant fiber

A spinning dope, anti-creep technology, applied in spinning solution preparation, dry spinning, fiber processing, etc., can solve the problems of poor heat resistance, poor dimensional stability, easy creep of polyethylene fibers, etc. Long life, high stability, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

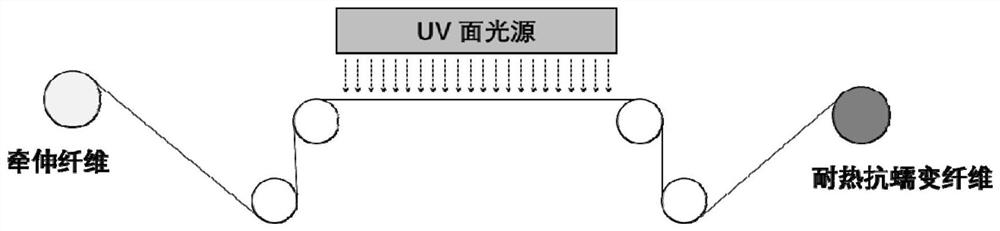

Method used

Image

Examples

preparation example 1

[0050] A preparation method of a photoinitiator, the concrete steps are:

[0051] (1) put azobisisobutyronitrile, xylene, 4-acryloyloxybenzophenone into the three-necked flask, carry out the polymerization reaction under argon, the reaction temperature is 60 ℃, and the reaction time is 2 hours; wherein , the content of azobisisobutyronitrile is 10wt% of the total mass of 4-acryloyloxybenzophenone; the ratio of moles of 4-acryloyloxybenzophenone to the volume of xylene is 1mol:1L ;

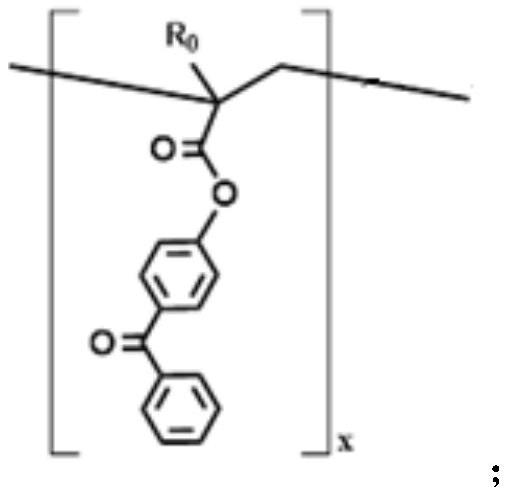

[0052] (2) adopting the method of vacuum distillation to remove unreacted monomers and solvent, carry out vacuum drying, drying temperature 60°C, drying time 12h, to obtain photoinitiator I; wherein, the process conditions of vacuum distillation are: at 80°C Condition, gradually reduce the pressure to boiling until the solvent is completely evaporated. The structural formula of the obtained photoinitiator I is:

[0053]

[0054] where x is an integer, R 0 is a hydrogen atom; its number-avera...

preparation example 2

[0056] A preparation method of a photoinitiator, the concrete steps are:

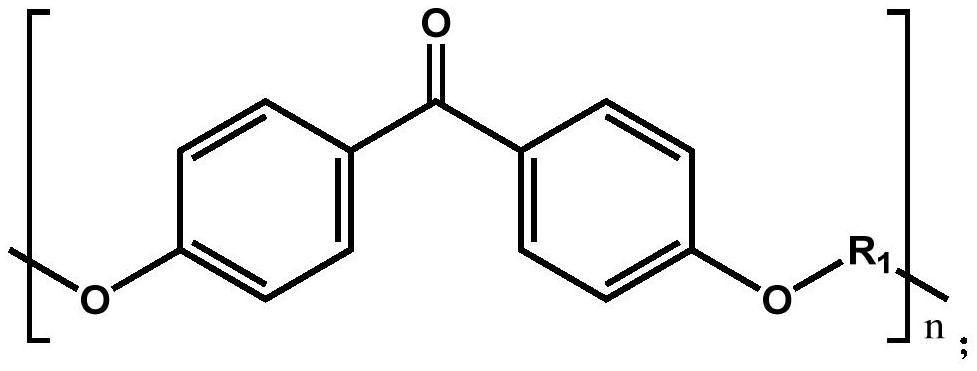

[0057] (1) azobisisobutyronitrile, xylene, 4-acryloyloxybenzophenone, and acrylic acid are subjected to a copolymerization reaction under argon, the reaction temperature is 65° C., and the reaction time is 3 hours; wherein, The content of azobisisobutyronitrile is 2wt% of the total mass of 4-acryloyloxybenzophenone; the mole number of 4-acryloyloxybenzophenone is X, and the mole number of acrylic acid is Y, wherein, The relationship between X and Y is: X:(X+Y)=0.05; The ratio of the total moles of 4-acryloyloxybenzophenone and acrylic acid to the volume of xylene is 2mol:1L;

[0058](2) adopting the method of vacuum distillation to remove unreacted monomers and solvent, carry out vacuum drying, drying temperature is 60°C, drying time is 12h, to obtain photoinitiator I; wherein, the process conditions of vacuum distillation are: at 40°C Condition, gradually reduce the pressure to boiling until the solve...

preparation example 3

[0063] A preparation method of a photoinitiator, the concrete steps are:

[0064] (1) azobisisobutyronitrile, xylene, 4-acryloyloxybenzophenone, and styrene are subjected to a copolymerization reaction under argon, the reaction temperature is 70° C., and the reaction time is 4 hours; wherein , the content of azobisisobutyronitrile is 0.05wt% of the total mass of 4-acryloyloxybenzophenone; the mole number of 4-acryloyloxybenzophenone is X, and the mole number of styrene is Y , wherein the relationship between X and Y is: X:(X+Y)=0.3; the ratio of the total moles of 4-acryloyloxybenzophenone and styrene to the volume of xylene is 2mol:1L;

[0065] (2) adopting the method of vacuum distillation to remove unreacted monomers and solvent, carry out vacuum drying, drying temperature is 60°C, drying time is 12h, to obtain photoinitiator I; wherein, the process conditions of vacuum distillation are: at 40°C Condition, gradually reduce the pressure to boiling until the solvent is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com