Preparation device of vapor chamber wick and preparation method of wick

A technology for preparing a device and a liquid absorbing core, which is applied in the field of preparing devices for a liquid soaking core of a vapor chamber, can solve the problems of increased material cost, low thermal resistance coefficient heat dissipation power, complicated process, etc., and achieves low equipment and processing costs, low thermal resistance. coefficient, the effect of high heat dissipation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

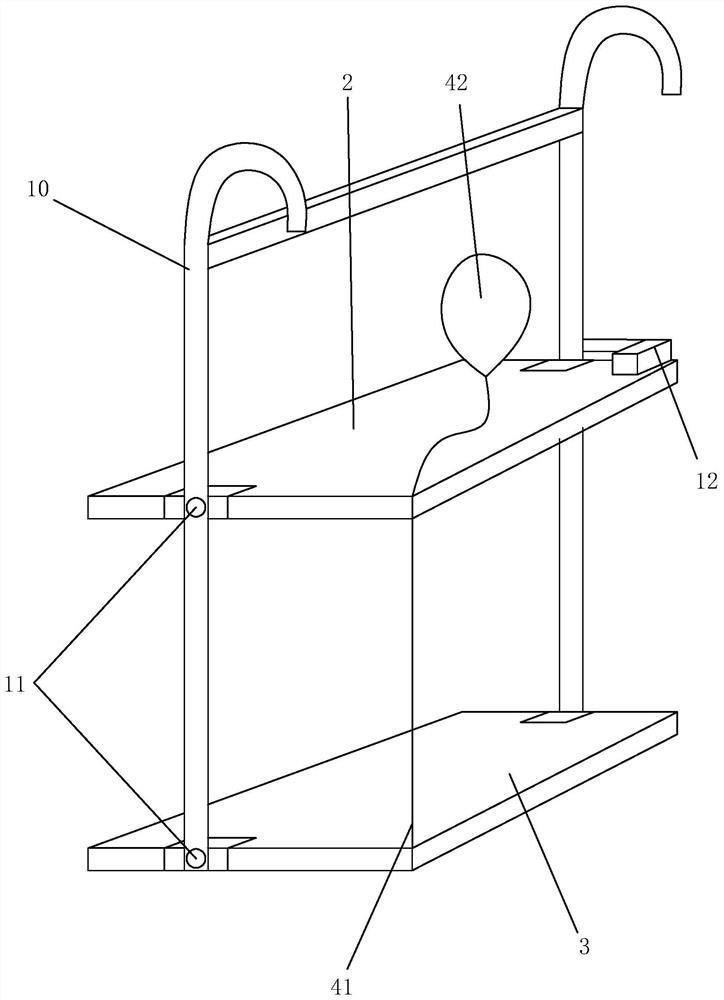

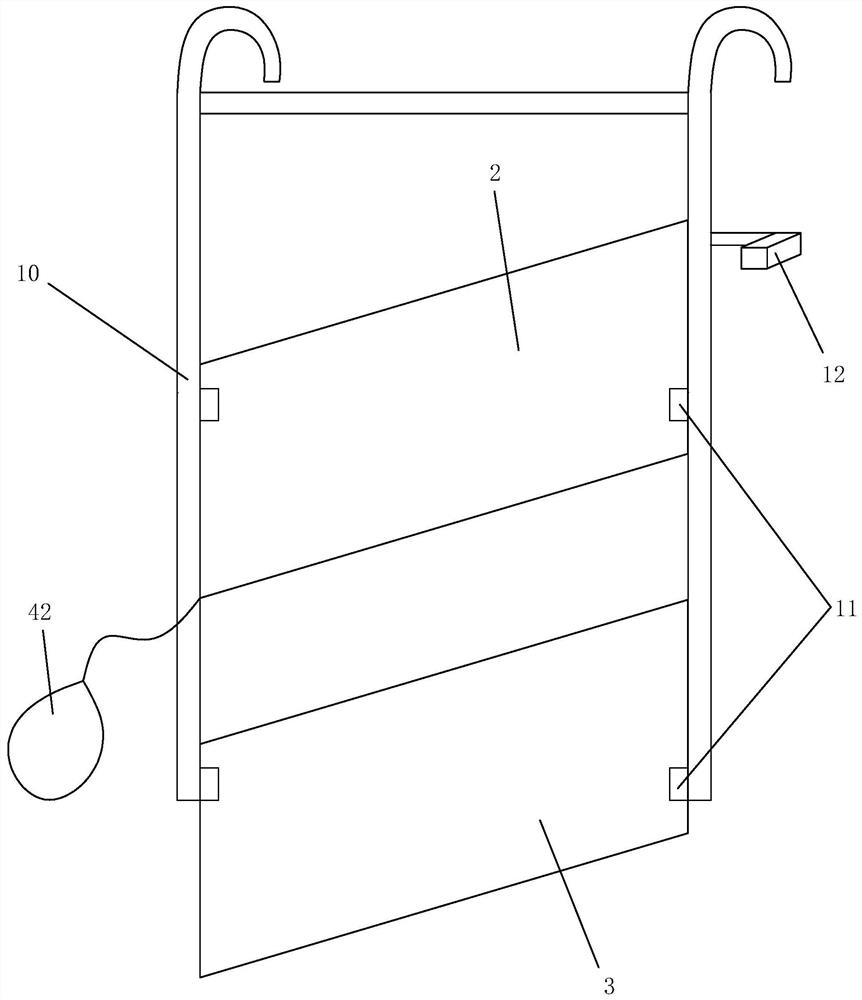

[0035] like figure 1 As shown, the present application is a preparation device for a soaking plate liquid absorbent core, including an electroplating hanger 1 , an upper plate 2 , a lower plate 3 , a rotating mechanism 11 and a buoyancy mechanism 4 .

[0036] The present application provides an apparatus for preparing a liquid absorbent core for a vapor chamber, including an electroplating hanger, wherein the electroplating hanger includes two fixed rods 10 that are vertically arranged opposite each other, and are hinged to one of the two fixed rods 10 through a rotating mechanism 11 . The upper plate 2 and the lower plate 3 between the upper plate 2 and the lower plate 3, the rotating mechanism 11 is arranged at the offset of the center of gravity of the upper plate 2 and the lower plate 3, so that the upper plate 2 and the lower plate 3 are not placed When entering the electrolyte, it is in a vertical state, and a buoyancy mechanism 4 is provided at the offset of the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com