High power LED module for spot illumination

A technology of light-emitting modules and light-emitting diodes, which is applied to the components of lighting devices, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problems of high-power LED lamp inclusion, etc., to increase the working life and reduce the working temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

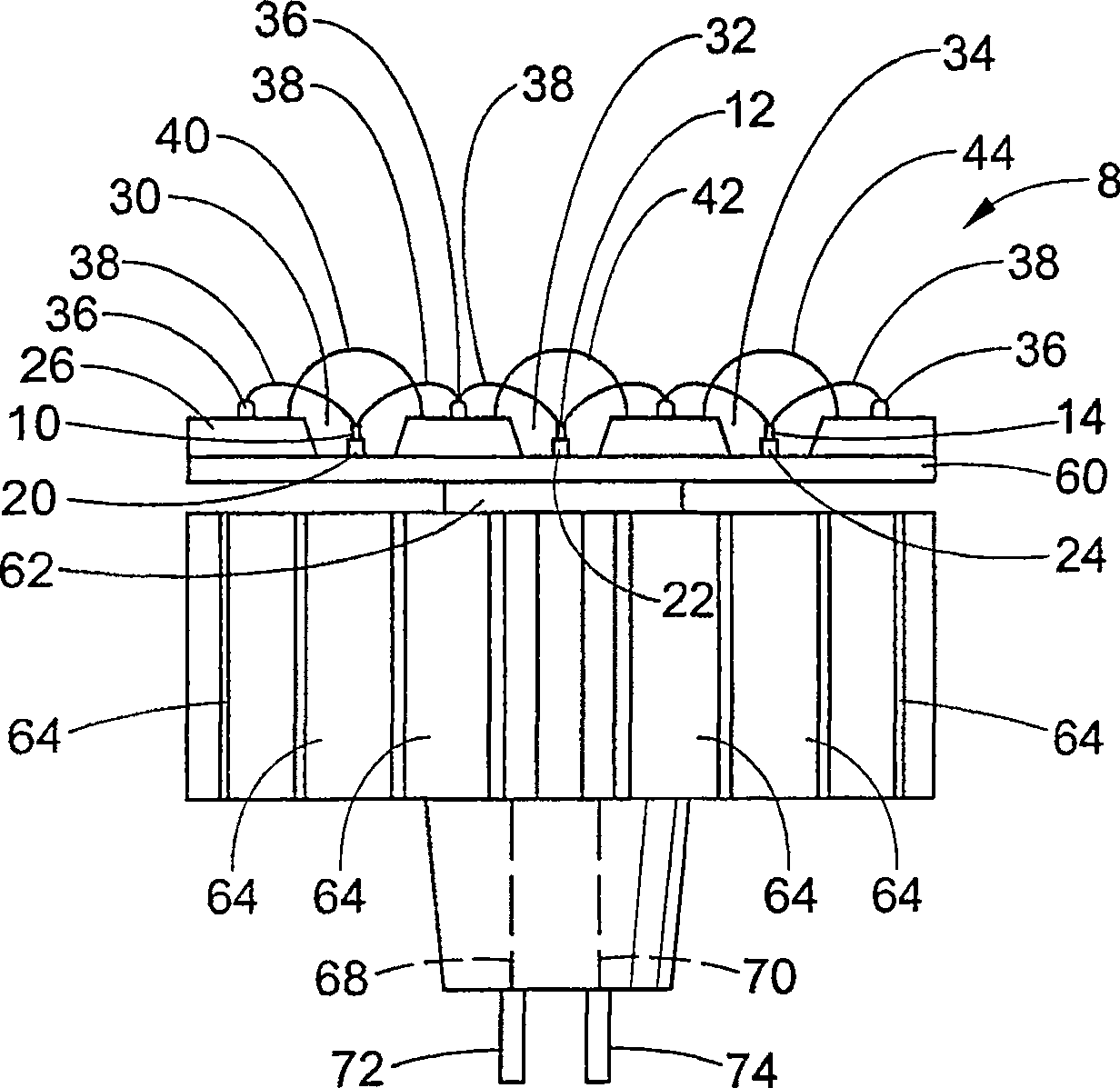

[0022] refer to figure 1 , device 8 includes an integrated array of high power LEDs 10, 12, 14 mounted to respective electrical insulator submounts 20, 22, 24, respectively. The submounts 20 , 22 , 24 are secured to a metal backside substrate 26 within respective wells 30 , 32 , 34 . Alternatively, the LEDs 10, 12, 14 are secured directly to the metal substrate 26, thereby eliminating the need for a submount. The wells 30, 32, 34 in which the LEDs 10, 12, 14 are located are typically stamped or drilled directly into the substrate material so as to preferably form a "reflector" shape. However, other LED and well configurations are also foreseen. The submounts 20, 22, 24 (or alternatively the LEDs 10, 12, 14) are secured by a highly thermally conductive material such as solder, filled epoxy, heat tape, and / or other materials with good thermal conductivity. adhesive) to the backside substrate 26 as a heat sink. LEDs 10 , 12 , 14 are connected to electrical contacts 36 by cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com