Composition for removing copper ions in waste liquid and application thereof

A technology of composition and copper ions, applied in the direction of water pollutants, metallurgical wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of high use cost, high cost, cumbersome steps, etc., and achieve improved removal efficiency and effect, The effect of reducing process pressure and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

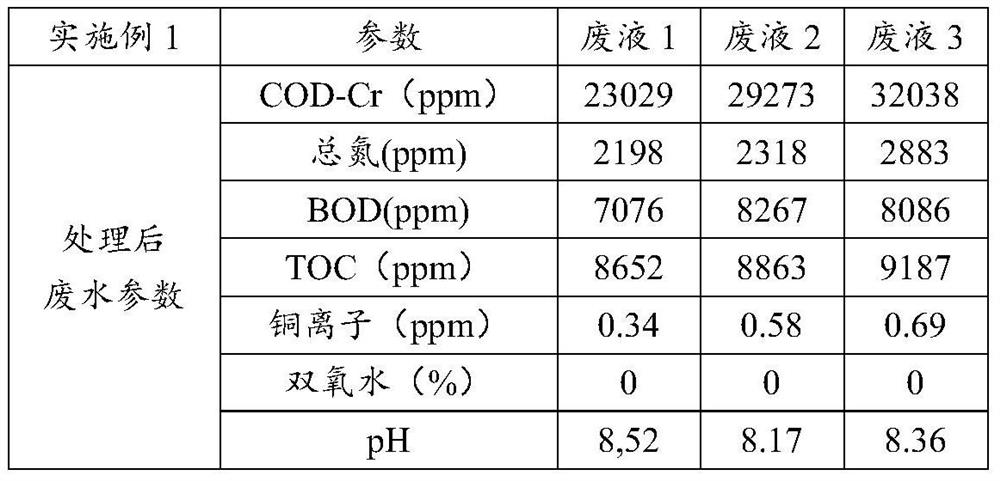

Embodiment 1

[0030] Embodiment 1 A first aspect provides a composition for removing copper ions in waste liquid. The raw material dosage of the composition is calculated as the mass percentage of the total mass of the waste liquid: 2% of ferrous ion source, 2% of alkaline hydroxide %, sulfide ion source 0.8%, sedimentation agent 0.5%.

[0031] The ferrous ion source is ferrous hydroxide, the alkaline hydroxide is a 10wt% sodium hydroxide aqueous solution, the sulfide ion source is a 35wt% sodium hydrosulfide aqueous solution, and the precipitation agent is a 2wt% PAM solution.

[0032] In this example, the sedimentation agent was purchased from the PAM sedimentation agent product sold by Gongyi Jiajie Filter Material Co., Ltd.

[0033] The second aspect of this embodiment provides a method for using the above composition. The steps include the following steps: (1) adding a ferrous ion source to the waste liquid, and stirring for 4 hours; (2) after the stirring is completed, adding alkaline...

Embodiment 2

[0037] The specific implementation of this embodiment is the same as that of Embodiment 1, except that the addition amount of the ferrous ion source is 1%.

[0038] The treated waste liquid is as follows:

[0039]

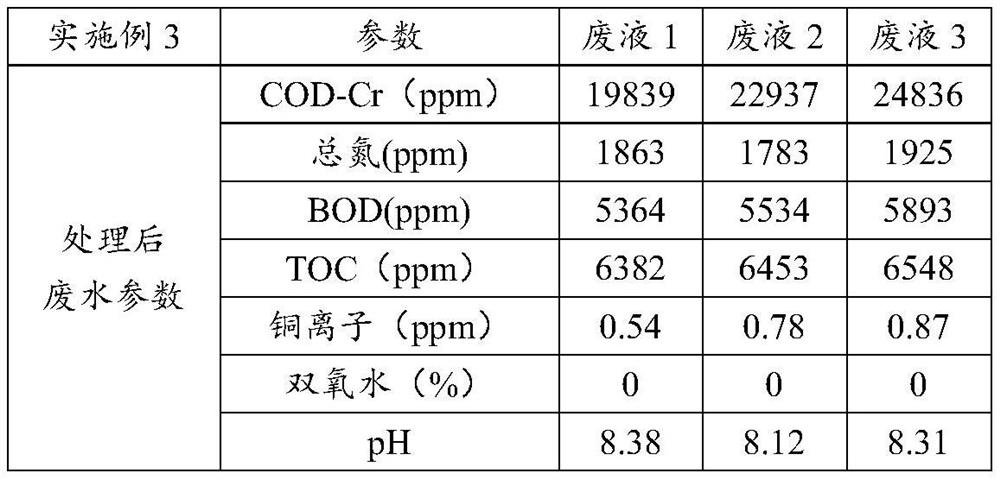

Embodiment 3

[0041] The specific implementation of this embodiment is the same as that of Embodiment 1, except that the addition amount of the ferrous ion source is 3%.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com