Bundled bullet release device with primary and secondary structure

A release device and bundled technology, which is applied in the direction of warheads, ammunition, weapon accessories, etc., can solve the problems of complex structure and process, high impact and vibration of bullets, high production cost, etc., to simplify design pressure, reduce process pressure, and release quickly reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

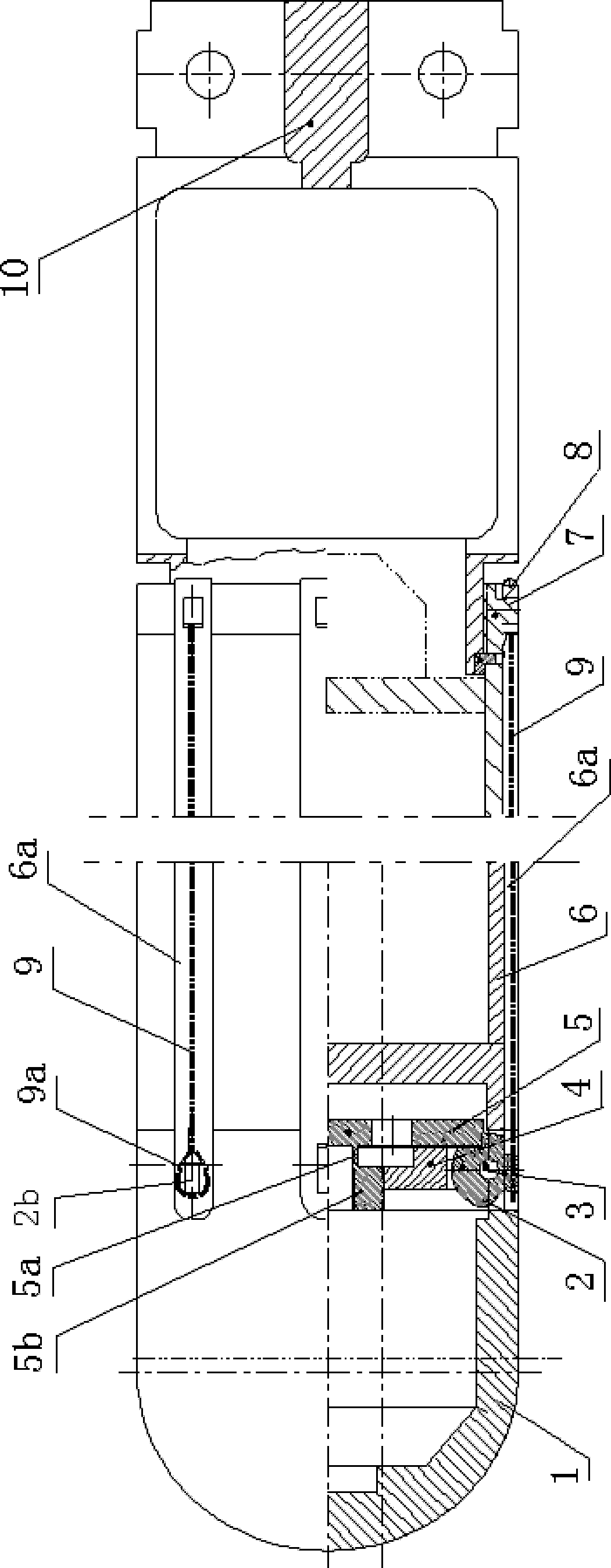

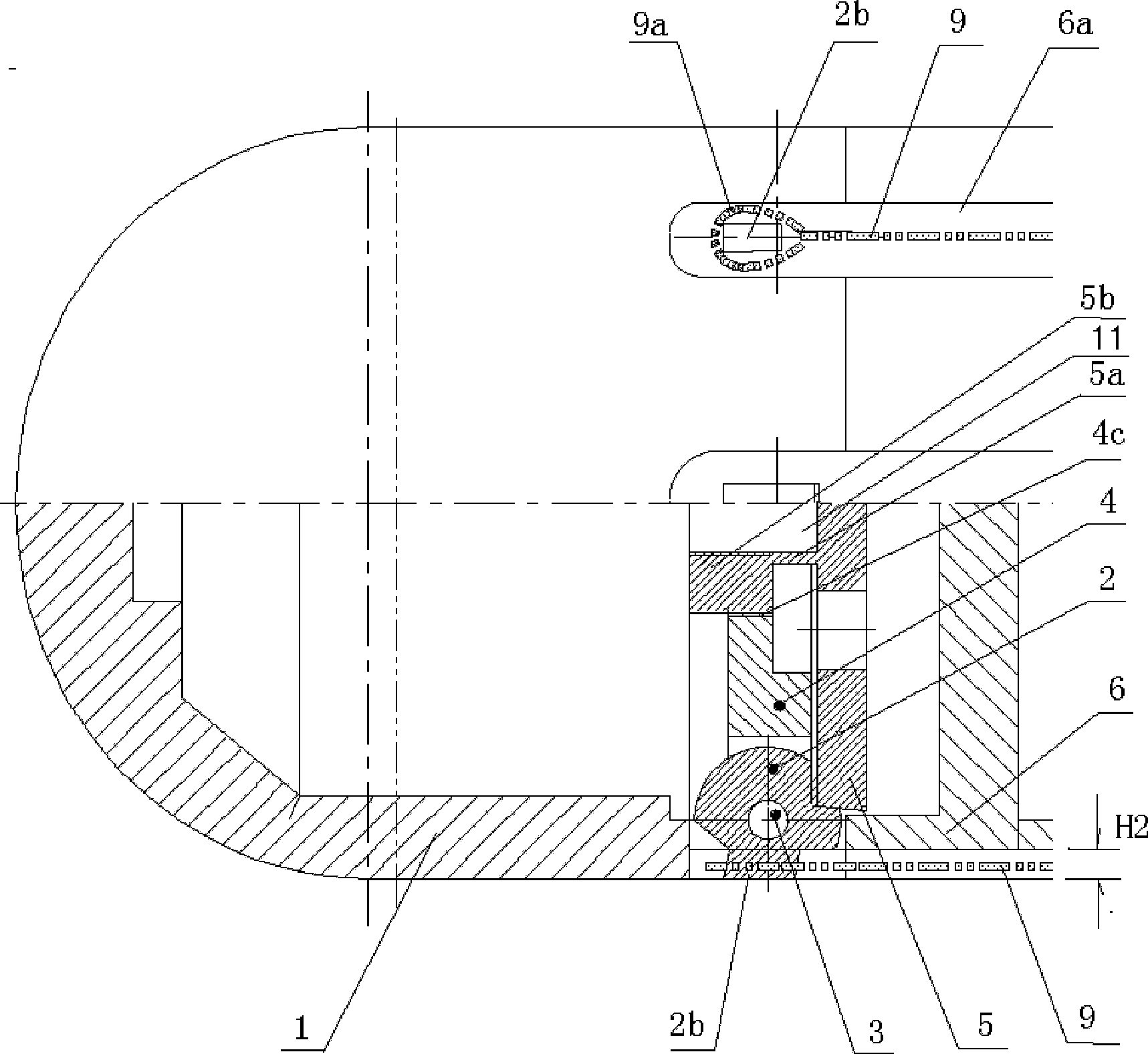

[0020] Such as figure 1 , figure 2 : the bullet release device of the present invention's binding type sub-female structure includes a binding mechanism and a release mechanism that are connected between the parent body, the bullet and the empennage seat, and its parent body is a head cap 1, and the release mechanism is installed at the opening of the cylinder section of the head cap 1 , the release mechanism includes a toothed ring 4 connected to the head cap 1, a plurality of pairs of shaft seats 4a are arranged around the toothed ring 4, the axis of the shaft seats 4a is parallel to the tangent line of the toothed ring 4, and on the toothed ring 4 in the middle of each pair of shaft seats 4a There is a radial rotary block opening 4b, and the corresponding position of the head cap 1 has an axial rotary block opening 1b, and the rotary block 2 is installed on each pair of shaft seats 4a through the rotating shaft 3; the rotary block 2 has a positioning notch 2a and a hook bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com