High purity cyclic peptide compound and preparation method and application thereof

A compound and high-purity technology, applied in the field of high-purity cyclic peptide compounds and their preparation, can solve problems such as low product purity, ineffective removal of impurities, and large amounts of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0293] Preparation of crude compound I

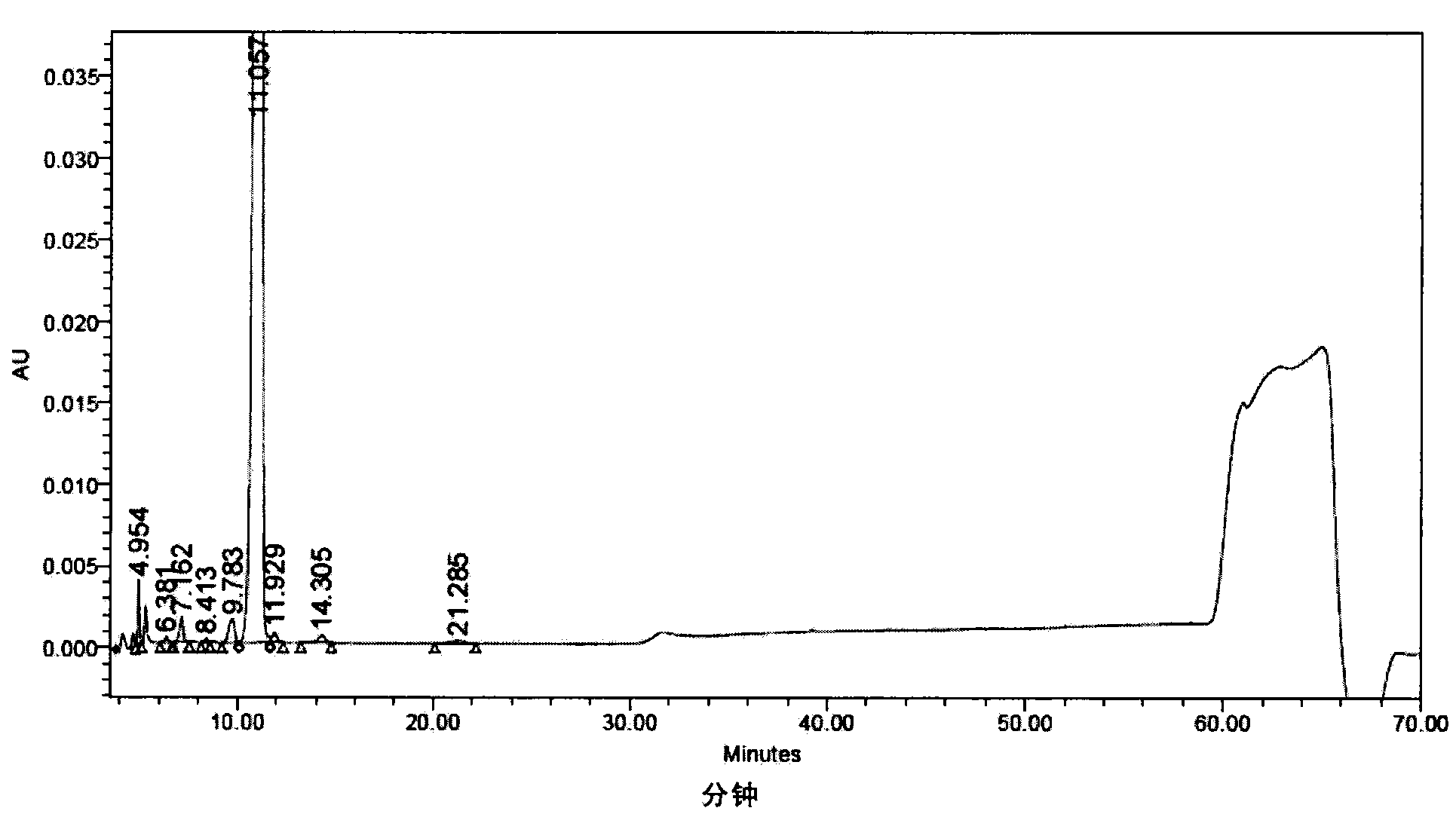

[0294] Referring to the method of Example 1 of US Patent No. 5,376,634, 76 g of solid powder of Compound I was prepared, and the content determined by HPLC was 97.51%, see figure 1 HPLC analysis spectrum.

[0295] Table 1

[0296] Impurity name

Embodiment 2

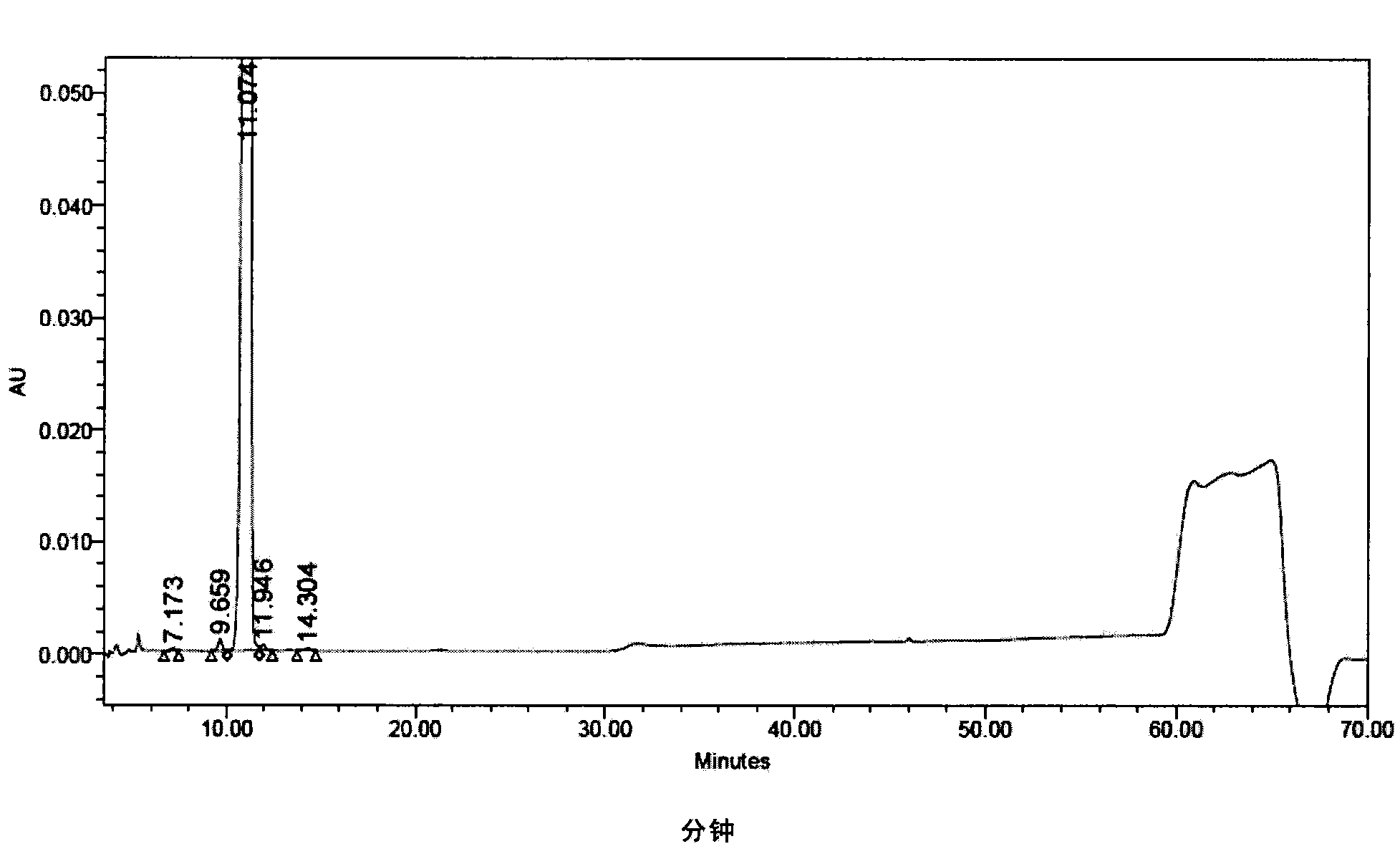

[0298] Preparation of high-purity formula I compound

[0299] At 30° C., 3.6 g of the crude compound I prepared in Example 1 was dissolved in a mixed solution of 25 ml of water and 20 ml of n-propanol, and stirred to completely dissolve the compound I. Glacial acetic acid was used to adjust the pH to 3.5, and the solution was cooled to 15°C, the crystals of Compound I were precipitated, and the stirring was continued at 15°C for 5 hours, so that the crystals of Compound I gradually grew. 90 ml of n-propanol was added dropwise, and after completion of the dropwise addition, the mixture was stirred at 15° C. for 1 hour. Suction filtration and vacuum drying afforded 3.5 g of compound I with a purity of 99.00% as determined by HPLC. The contents of the main relevant impurities are shown in Table 2.

[0300] Table 2

[0301] Impurity name

Embodiment 3

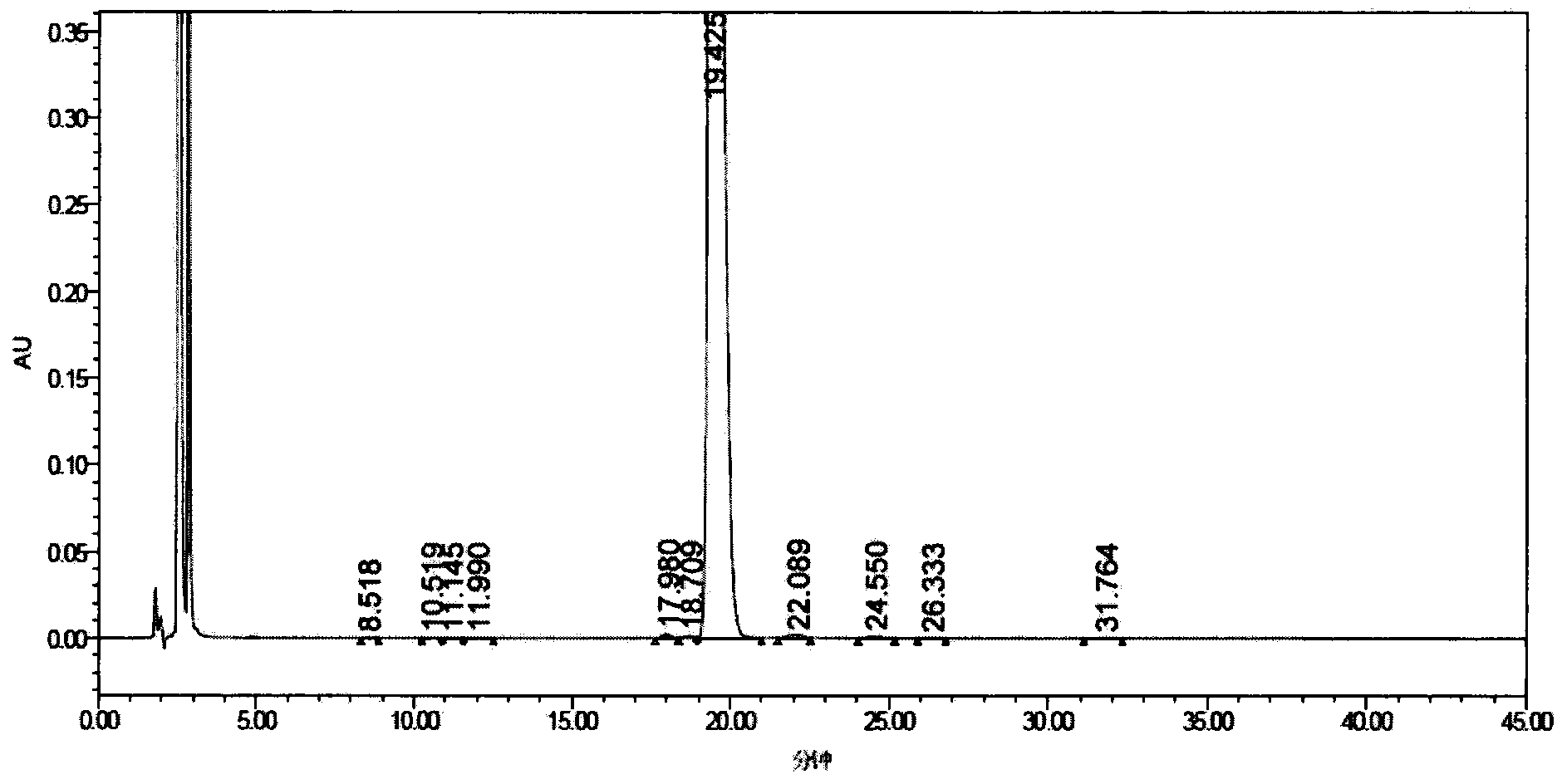

[0303] Preparation of high-purity formula I compound

[0304] At 40°C, 3.5g of Compound I prepared in Example 2 (Compound I prepared in Example 2, with an HPLC purity of 99.00%) was dissolved in a mixed solution of 19ml of water and 16ml of n-propanol, and stirred to make the compound I dissolve completely. Glacial acetic acid was used to adjust the pH to 2.0, and the solution was cooled to 15°C, the crystals of compound I were precipitated, and the stirring was continued at 15°C for 5 hours, so that the crystals of compound I grew gradually. 70 ml of n-propanol was added dropwise, and after the dropwise addition was completed, the mixture was stirred at 15° C. for 1 hour. Suction filtration and vacuum drying afforded 3.4 g of compound I with a purity of 99.23% as determined by HPLC. The content of relevant impurities is shown in Table 3.

[0305] table 3

[0306] Impurity name

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com