High-temperature-resistant synchronous motor magnetic steel and preparation method thereof

A technology for synchronous motors and high temperature resistance, which is applied in the manufacture of inductors/transformers/magnets, circuits, magnetic objects, etc., and can solve problems such as poor high temperature resistance, large temperature coefficient, and low Curie temperature of sintered NdFeB magnets , to achieve the effect of improving magnetic properties, high mechanical strength, improving grain size and grain morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

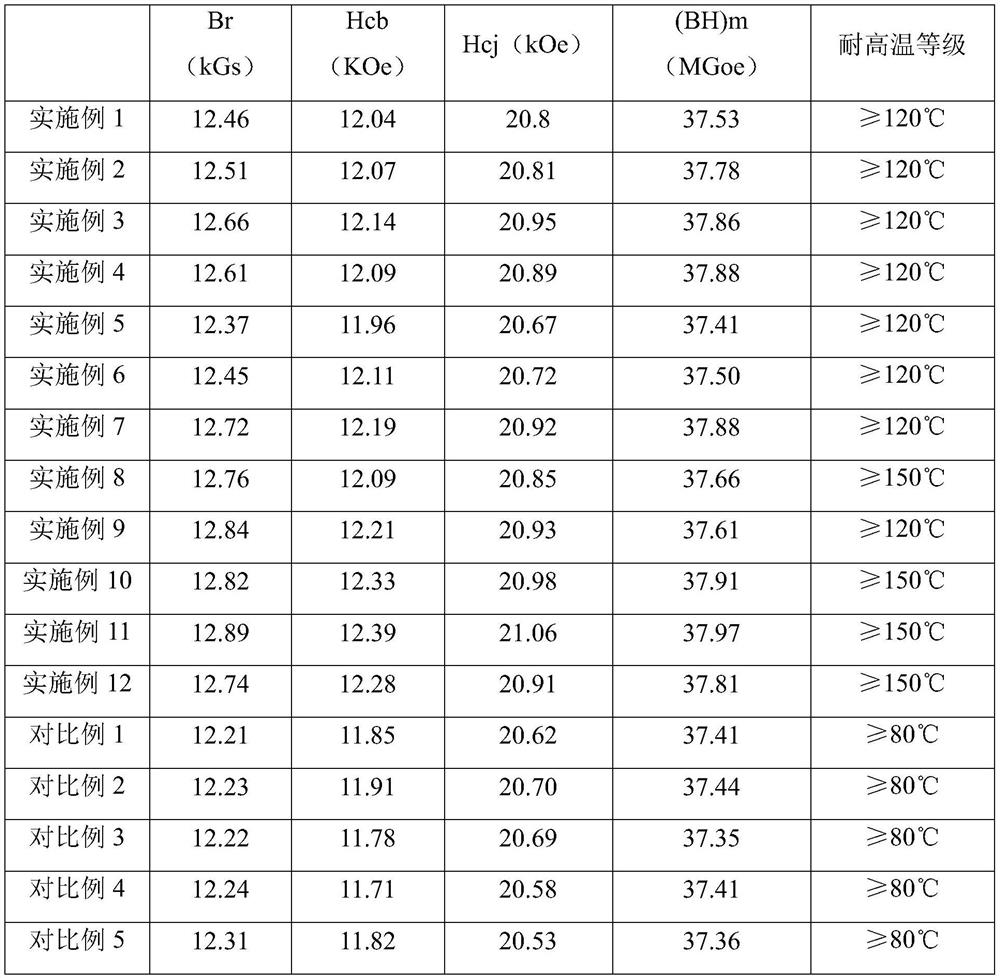

Examples

Embodiment 1-4

[0031] A high temperature resistant synchronous motor magnetic steel is prepared according to the following method with reference to the ratio in Table 1:

[0032] S1. Put the raw materials of the alloy main body into a vacuum reactor, smelt at 1650 ° C, cast into 0.5mm thick slabs after smelting, and crush the slabs into coarse powder by hydrogen breaking reaction in a hydrogen breaking furnace, Then add gasoline accounting for 0.03% of the total mass of the coarse powder as a lubricant to carry out jet milling, and jet milling until the median particle size of the main alloy powder is 4 μm;

[0033] S2. Add silicon nitride powder accounting for 0.3% of the total mass of the alloy body powder to the alloy body powder, mix evenly, then add gasoline accounting for 0.02% of the total mass of the alloy body powder as a lubricant, and add 0.02% of the total weight of the alloy body powder. The phosphite is used as an antioxidant, and the mixture is uniformly mixed. Under the prote...

Embodiment 5

[0038] A high temperature resistant synchronous motor magnetic steel, the proportion of each component of the alloy body is prepared by the following method with reference to Example 3:

[0039] S1. Put the raw materials of the alloy main body into a vacuum reactor, smelt at 1800 ° C, cast into 0.75mm thick slabs after smelting, and crush the slabs into coarse powder by hydrogen breaking reaction in a hydrogen breaking furnace, Then add gasoline accounting for 0.05% of the total mass of the coarse powder as a lubricant to carry out jet milling, and jet milling until the median particle size of the main alloy powder is 5 μm;

[0040] S2. Add silicon nitride powder accounting for 0.3% of the total mass of the alloy body powder to the alloy body powder, mix evenly, then add gasoline accounting for 0.04% of the total mass of the alloy body powder as a lubricant, and add 0.05% of the total weight of the alloy body powder. Phosphite is used as antioxidant, mixed evenly, under the pr...

Embodiment 6

[0043] A high temperature resistant synchronous motor magnetic steel, the proportion of each component of the alloy body is prepared by the following method with reference to Example 3:

[0044] S1. Put the raw materials of the alloy main body into a vacuum reactor, smelt at 1700 ° C, cast into a 0.75mm thick slab after smelting, and crush the slab into coarse powder by hydrogen breaking reaction in a hydrogen breaking furnace, Then add gasoline accounting for 0.03% of the total mass of the coarse powder as a lubricant to carry out jet milling, and jet milling until the median particle size of the main alloy powder is 5 μm;

[0045] S2. Add silicon nitride powder accounting for 0.3% of the total mass of the main alloy powder to the main alloy powder, mix evenly, then add gasoline accounting for 0.03% of the total mass of the main alloy powder as a lubricant, and add 0.04% of the total mass of the main alloy powder. The phosphite is used as an antioxidant, and the mixture is un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com