Ultraviolet light detector with titanium dioxide nanotube array serving as matrix and preparation method thereof

A nanotube array and titanium dioxide technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that the UV-visible suppression ratio cannot be improved, the time response performance of the detector is deteriorated, and the dark current of the detector is large, etc. problem, to achieve the effect of high UV-visible suppression ratio, good time response performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

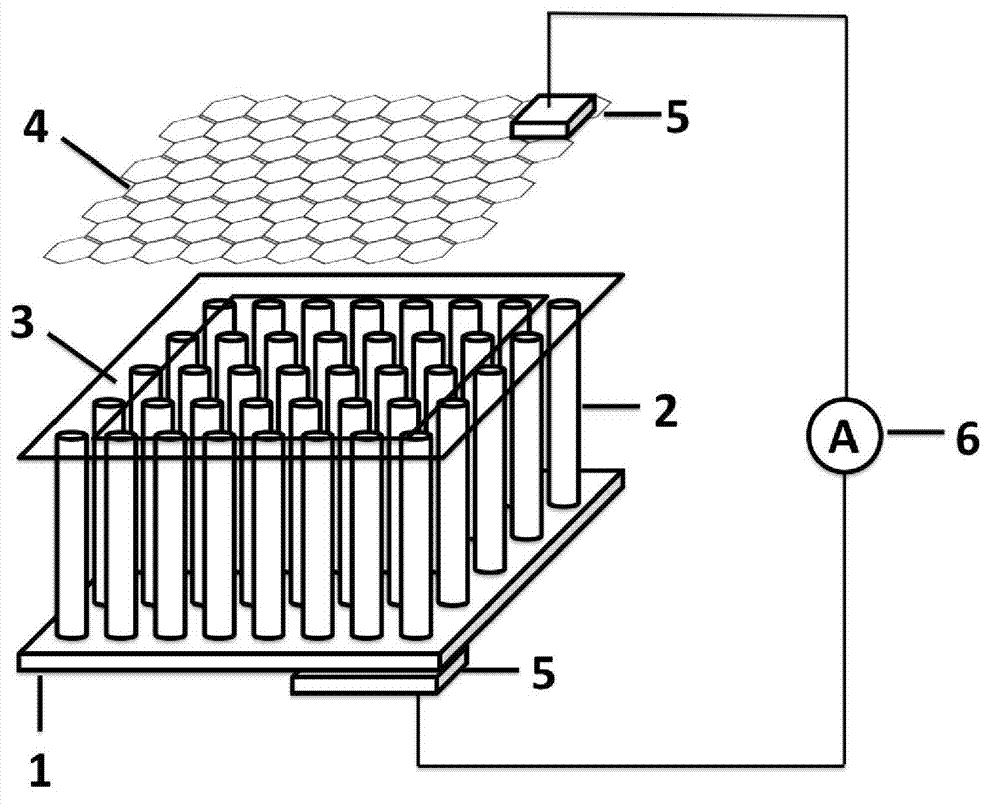

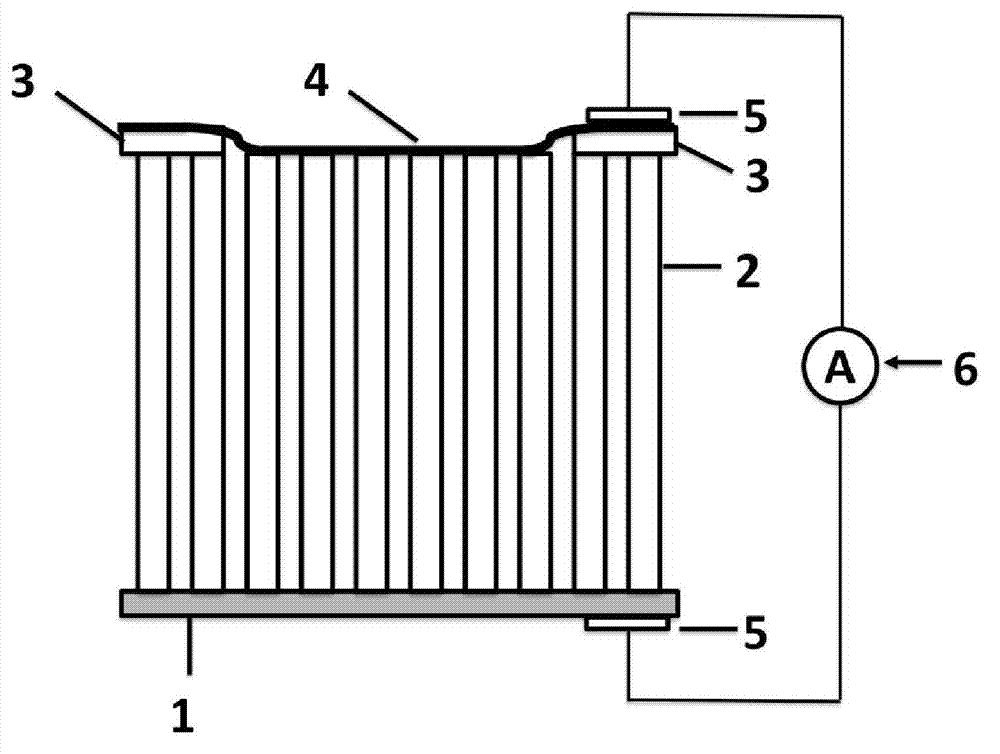

[0030] In this embodiment, the ultraviolet light detector based on the titanium dioxide nanotube array is composed of a titanium sheet substrate 1, a titanium dioxide nanotube array 2, an insulating layer 3 and a graphene film 4 from bottom to top, The lower surface of the titanium sheet substrate 1 and the upper surface of the graphene film 4 are respectively provided with extraction electrodes 5, and the extraction electrodes 5 are connected by a current measuring device 6;

[0031]The insulating layer 3 is a PET film with a frame-shaped hollow structure, the graphene film 4 is in contact with the insulating layer 3, and the graphene film 4 forms a Schottky contact with the titanium dioxide nanotube array 2;

[0032] The extraction electrode 5 is a silver electrode, and the extraction electrode 5 forms an ohmic contact with the graphene film 4 , and the extraction electrode 5 forms an ohmic contact with the titanium substrate 1 .

[0033] The specific preparation method is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com