Conductive silver aluminum paste, preparation method, electrode and battery

A conductive silver and aluminum paste technology, which is applied to conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as low minority carrier lifetime, increased light-induced attenuation, and restrictions on P-type silicon , to achieve the effect of reducing bulk resistance, reducing damage and improving contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment GA01-GA06

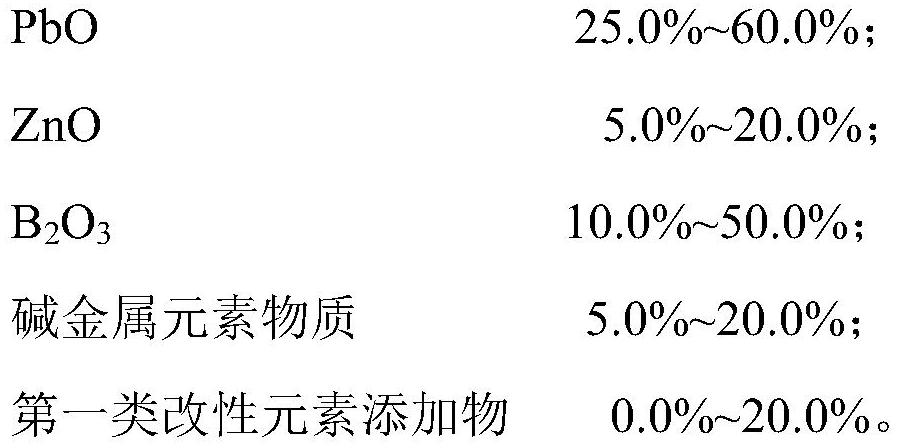

[0053] Preparation of the first type of glass powder: Calculate and weigh the first type of glass powder using raw materials according to the set formula. The added alkali metal oxide is the carbonate corresponding to the oxide. The properties of the carbonate It is more stable and not easy to be oxidized and deteriorated. Then mix the raw materials evenly, add them into the crucible, put the crucible in the muffle furnace, and keep the temperature at 750℃-1100℃ for 20-60min. After the raw materials are completely melted and reacted, take them out and pour the glass liquid into the crucible. Enter the low-temperature counter-roller or low-temperature ice tank to cool the high-temperature glass liquid, and then use high-speed airflow and cold air to dry at room temperature to obtain glass particles, and then add the dried glass particles to a disc mill and grind it into primary under the disc gap of 50-200 microns. Glass powder, and finally the primary glass powder is pulverized...

Embodiment GB01-GB06

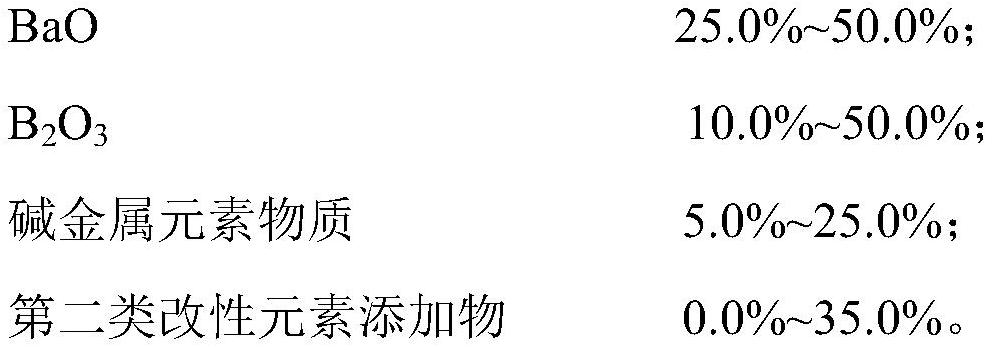

[0058] Preparation of the second type of glass powder: Calculate and weigh the raw materials of the second type of glass powder according to the set formula. The added alkali metal oxide is the carbonate of the corresponding proportion of the oxide, and BaO is the corresponding proportion. BaCO 3 , then mix the raw materials evenly, add them into the crucible, then put the crucible in the muffle furnace, keep the temperature at 750℃-1100℃ for 20-60min, take out the raw materials after the complete melting reaction, pour the glass liquid into the low-temperature counter-roller or low-temperature The ice tank is cooled, and then the glass particles are obtained by drying at room temperature with high-speed airflow and cold air. Then, the dried glass particles are added to the disc mill and crushed into primary glass powder under the disc gap of 50-200 microns. Finally, the primary glass powder is passed through the airflow. The pulverizer is crushed under the pressure of 6-12Mpa...

Embodiment O

[0062] Examples OC01-OC06:

[0063] Preparation of organic carrier: The prepared organic carrier raw materials are weighed according to the set formula ratio, stirred and mixed, and uniformly dispersed by high-speed centrifugation to obtain organic carriers OC01-OC06 for use. The composition ratio of each organic carrier is shown in Table 3.

[0064] Table 3 Organic carrier weight component table (wt%)

[0065] name OC01 OC02 OC03 OC04 OC05 OC06 Organic solvents 60.0 75.0 80.0 65.2 80.0 75.0 organic resin 2.5 1.0 9.8 3.0 cellulose 2.5 4.5 3.0 thickener 20.0 15.0 10.0 5.0 15.0 7.5 defoamer 15.0 10.0 9.0 20.0 0.5 11.5 total 100.0 100.0 100.0 100.0 100.0 100.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com