Automobile chassis part based on impact-resistant coating

A technology for impact-resistant coatings and automobile chassis, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of damage to automobile chassis parts, easy to be hit and rubbed by external objects, large in size, etc. Corrosion performance, effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The reinforcing agent includes the following raw materials: 10 g of polyether sulfone, 70 g of phenolphthalein-based polyether ketone, and 5 g of sodium dodecylbenzenesulfonate.

[0036] The enhancer is prepared by the following steps:

[0037] S1. Pour polyethersulfone and sodium dodecylbenzenesulfonate into 150 g of DMF solution, stir until dispersed uniformly, then dry at 140° C. for 4 h, remove the solvent, and obtain a mixture;

[0038] S2. The mixture obtained in step S1 and the phenolphthalein-based polyether ketone are screened with a 60-mesh screen, and then the screened mixed powder is dried in a vacuum oven at 120° C. for 3 hours, and finally stirred with an electric stirrer to obtain enhanced agent.

[0039] The epoxy resin is a mixture of aliphatic epoxy resin and alicyclic epoxy resin.

[0040] The modified graphene oxide includes the following raw materials: 10 g of graphene oxide and 3 g of bisphenol S.

[0041] The modified graphene oxide is prepared...

Embodiment 2

[0052] The reinforcing agent includes the following raw materials: 10 g of polyether sulfone, 90 g of phenolphthalein-based polyether ketone, and 3 g of sodium dodecylbenzenesulfonate.

[0053] The enhancer is prepared by the following steps:

[0054] S1. Pour polyethersulfone and sodium dodecylbenzenesulfonate into 200 g of DMF solution, stir until dispersed uniformly, then dry at 160° C. for 2 h, remove the solvent, and obtain a mixture;

[0055] S2. The mixture obtained in step S1 and the phenolphthalein-based polyether ketone are screened with a 60-mesh sieve, then the screened mixed powder is dried in a vacuum oven at 140°C for 1 hour, and finally stirred with an electric stirrer to obtain enhanced agent.

[0056] The modified graphene oxide includes the following raw materials: 10 g of graphene oxide and 5 g of bisphenol S.

[0057] The modified graphene oxide is prepared by the following steps:

[0058] (1) ultrasonically dispersing graphene oxide in 220 g of thionyl...

Embodiment 3

[0068] The reinforcing agent includes the following raw materials: 10 g of polyether sulfone, 80 g of phenolphthalein-based polyether ketone, and 4 g of sodium dodecylbenzenesulfonate.

[0069] The enhancer is prepared by the following steps:

[0070] S1. Pour polyethersulfone and sodium dodecylbenzenesulfonate into 180 g of DMF solution, stir until dispersed uniformly, then dry at 150° C. for 3 hours, remove the solvent, and obtain a mixture;

[0071] S2. The mixture obtained in step S1 and phenolphthalein-based polyether ketone are screened with a 60-mesh sieve, then the screened mixed powder is dried in a vacuum oven at 130 ° C for 2 hours, and finally stirred with an electric stirrer to obtain enhanced agent.

[0072] The modified graphene oxide includes the following raw materials: 10 g of graphene oxide and 4 g of bisphenol S.

[0073] The modified graphene oxide is prepared by the following steps:

[0074] (1) ultrasonically dispersing graphene oxide in 210 g of thio...

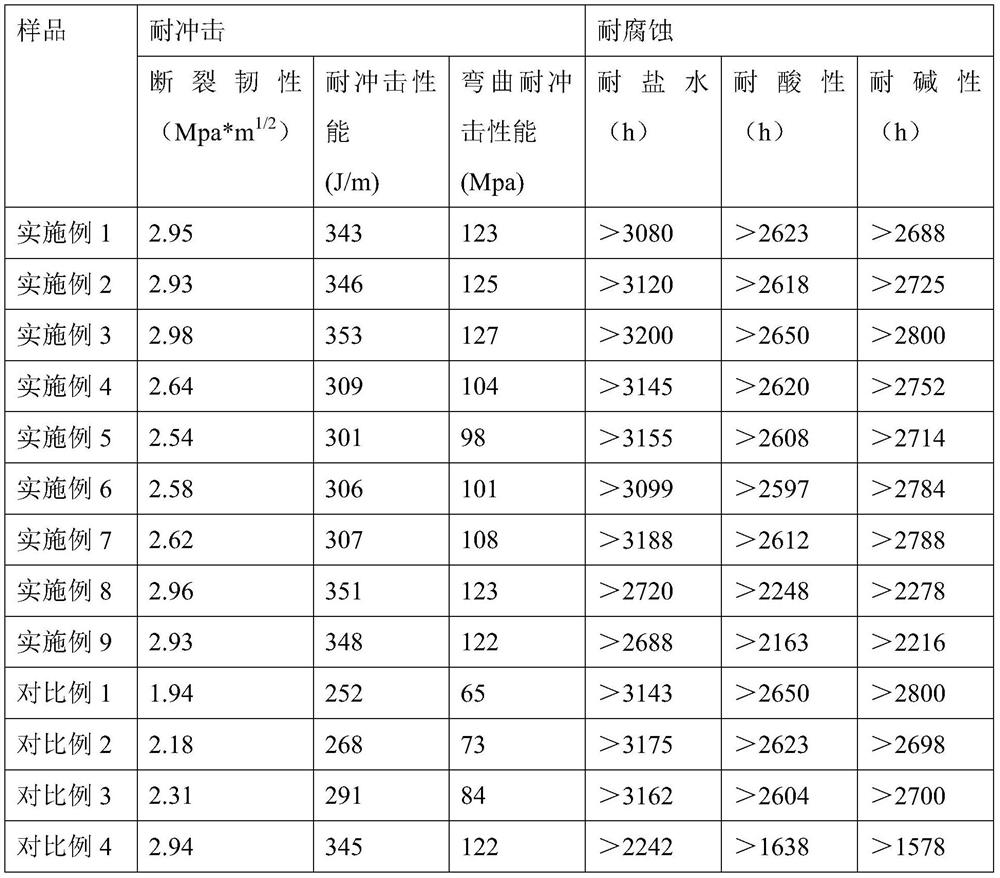

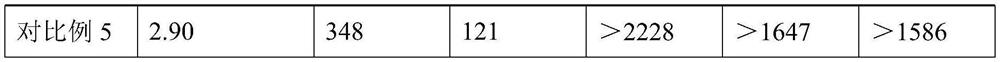

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com