Low-temperature co-fired ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics and slurry, applied in the field of low-temperature co-fired ceramic materials, which can solve problems such as excessively high resonance frequency temperature coefficient and low dielectric loss, achieve low dielectric loss and improve low-temperature sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The low-temperature co-fired ceramic material described in this embodiment, in terms of the total amount of its preparation raw materials, includes the following components in mass content:

[0052] BaTi 4 O 9 55wt%;

[0053] Mg 2 SiO 4 15wt%;

[0054] Low melting point glass powder 30wt%;

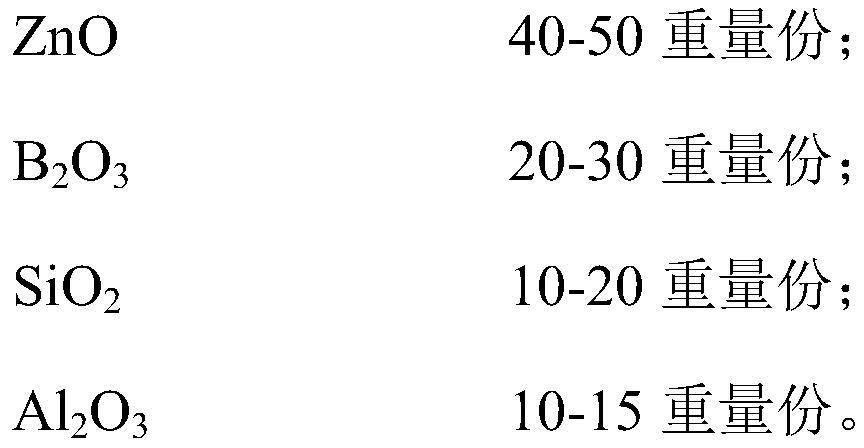

[0055] Wherein, the low melting point glass powder includes the following components by weight:

[0056]

[0057] The preparation method of the low-temperature co-fired ceramic material described in this embodiment includes the following steps:

[0058] (1) According to the selected stoichiometric ratio, weigh the corresponding weight of BaCO 3 , TiO 2 , adding water (material: water = 1: 1.2) and ammonium acrylate dispersant (accounting for 0.7wt% of the powder) and mixing, using a ball mill for pre-mixing for 3h, and after ball milling, using a horizontal sand mill (The grinding medium adopts 0.65mm zirconium balls) for further dispersion to obtain a uniformly disper...

Embodiment 2

[0068] The low-temperature co-fired ceramic material described in this embodiment, in terms of the total amount of its preparation raw materials, includes the following components in mass content:

[0069] BaTi 4 O 9 70wt%;

[0070] Mg 2 SiO 4 5wt%;

[0071] Low melting point glass powder 25wt%;

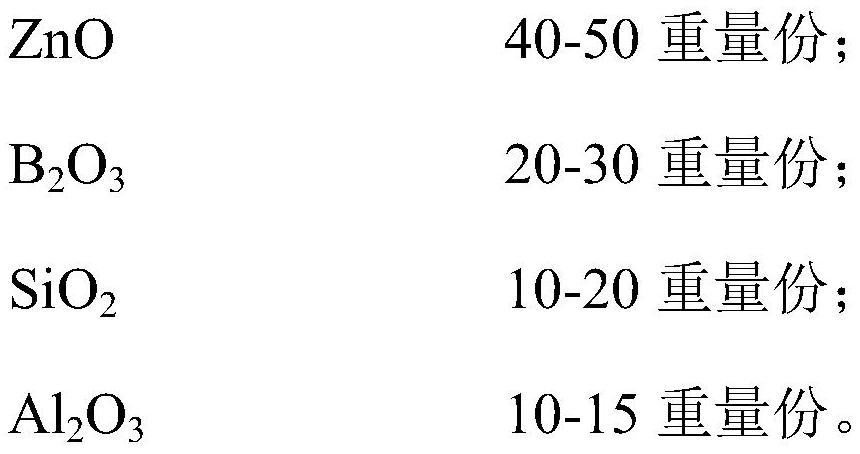

[0072] Wherein, the low melting point glass powder includes the following components by weight:

[0073]

[0074] BaTi described in this example 4 O 9 The preparation method of the base low temperature co-fired ceramic material comprises the following steps:

[0075] (1) According to the selected stoichiometric ratio, weigh the corresponding weight of BaCO 3 , TiO 2 , adding water (material: water = 1: 1.2) and ammonium acrylate dispersant (accounting for 0.8wt% of the powder) and mixing, using a ball mill for pre-mixing for 3h, and after ball milling, using a horizontal sand mill (The grinding medium adopts 0.65mm zirconium balls) for further dispersion to obtain a u...

Embodiment 3

[0083] The low-temperature co-fired ceramic material described in this embodiment, in terms of the total amount of its preparation raw materials, includes the following components in mass content:

[0084] BaTi 4 O 9 65wt%;

[0085] Mg 2 SiO 4 15wt%;

[0086] Low melting point glass powder 20wt%;

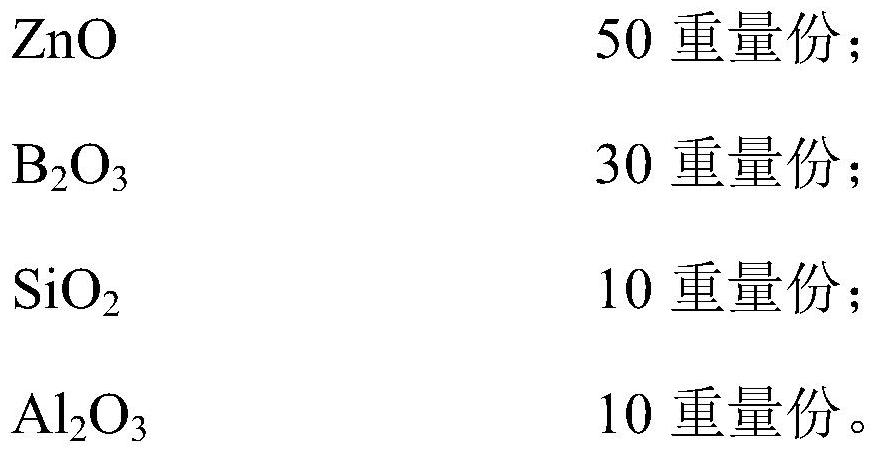

[0087] Wherein, the low melting point glass powder includes the following components by weight:

[0088]

[0089] The preparation method of the low-temperature co-fired ceramic material described in this embodiment includes the following steps:

[0090] (1) According to the selected stoichiometric ratio, weigh the corresponding weight of BaCO 3 , TiO 2 , adding water (material: water = 1: 1.3) and ammonium acrylate dispersant (accounting for 0.9wt% of the powder) and mixing, using a ball mill for pre-mixing for 3h, and after ball milling, using a horizontal sand mill (The grinding medium adopts 0.65mm zirconium balls) for further dispersion to obtain a uniformly disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com