Intermediate low-loss low-temperature co-fired ceramic material and preparation method thereof

A low-temperature co-firing and glass-ceramic technology, applied in the field of low-temperature co-firing ceramic materials, can solve the problems of restricted use and high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

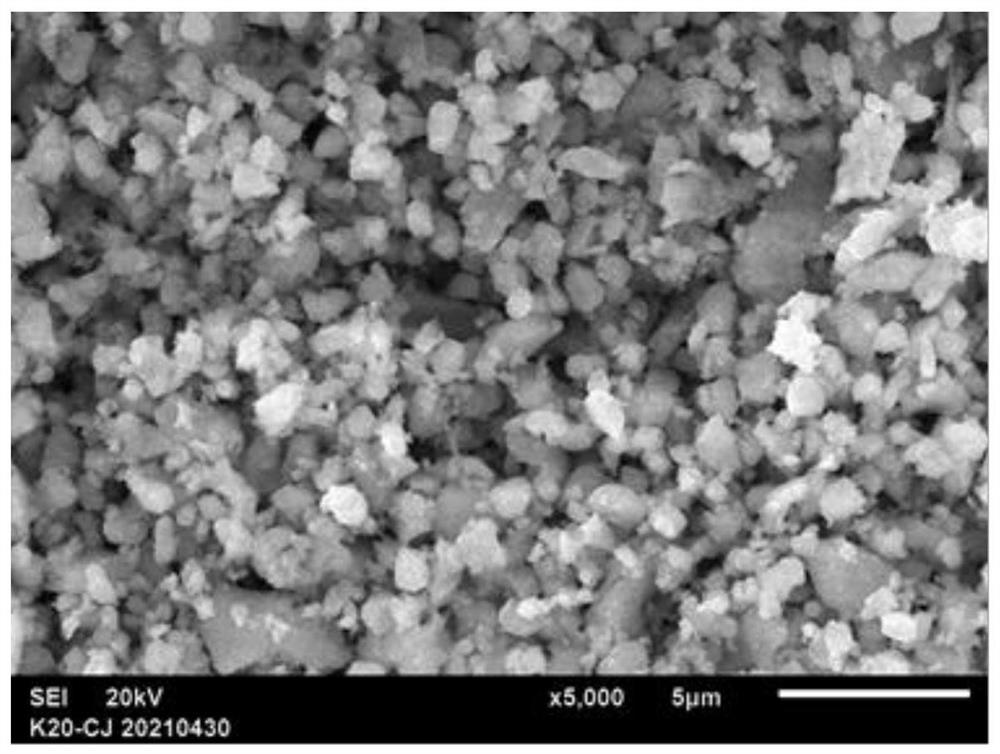

Image

Examples

Embodiment 1

[0055] Ba in this example 2 Ti 9 o 20 Based on the low-temperature co-fired ceramic material, based on the total amount of raw materials for its preparation, it includes the following components in mass content:

[0056] Ba2Ti9O20 55wt%;

[0057] Mg2SiO4 20wt%;

[0058] Low melting point glass powder 25wt%;

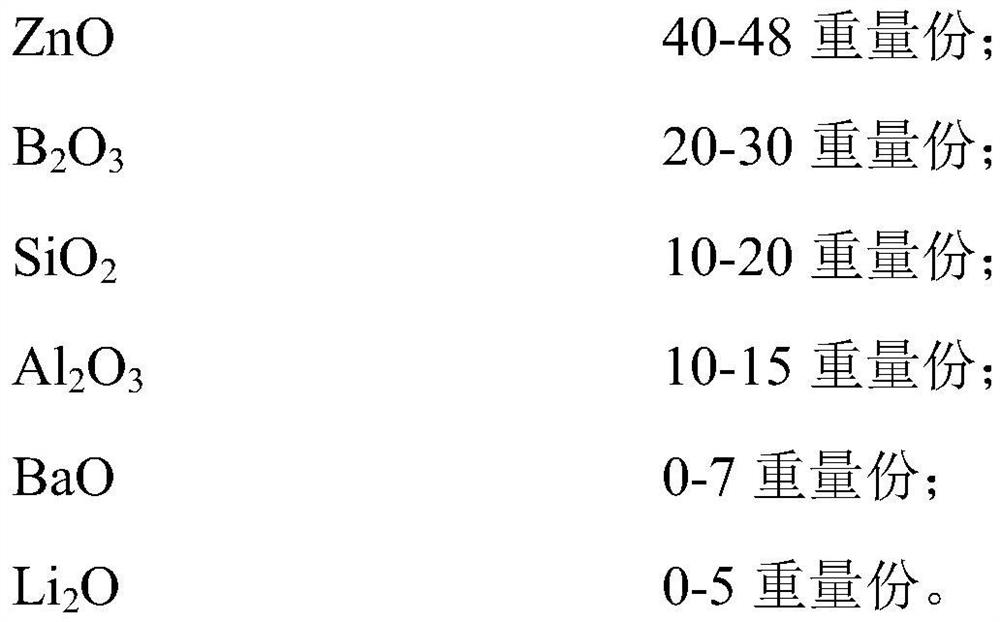

[0059] Wherein, the low-melting point glass powder includes the following components by weight:

[0060]

[0061] Ba in this example 2 Ti 9 o 20 A method for preparing a low-temperature co-fired ceramic material comprising the steps of:

[0062] (1) According to the selected mass content ratio, weigh the corresponding weight of BaTiO 3 、TiO 2 , add water (material: water=1:1.2) and ammonium acrylate dispersant (accounting for 0.7wt% of the powder amount) and mix evenly, use a ball mill to pre-mix for 3h, and then use a horizontal sand mill (the grinding medium adopts 0.65 mm zirconium balls) to disperse to obtain a uniformly dispersed slurry;

[0063] (2) U...

Embodiment 2

[0073] Ba in this example 2 Ti 9 o 20 Based on the low-temperature co-fired ceramic material, based on the total amount of raw materials for its preparation, it includes the following components in mass content:

[0074] Ba2Ti9O20 60wt%;

[0075] Mg2SiO4 15wt%;

[0076] Low melting point glass powder 25wt%;

[0077] Wherein, the low-melting point glass powder includes the following components by weight:

[0078]

[0079] Ba in this example 2 Ti 9 o 20 A method for preparing a low-temperature co-fired ceramic material comprising the steps of:

[0080] (1) According to the selected mass content ratio, weigh the corresponding weight of BaTiO 3 、TiO 2 , add water (material: water=1:1.1) and ammonium acrylate dispersant (accounting for 0.5wt% of the powder amount) and mix evenly, use a ball mill to pre-mix for 3h, and then use a horizontal sand mill (the grinding medium adopts 0.65 mm zirconium balls) to disperse to obtain a uniformly dispersed slurry;

[0081] (2) U...

Embodiment 3

[0090] Ba in this example 2 Ti 9 o 20 Based on the low-temperature co-fired ceramic material, based on the total amount of raw materials for its preparation, it includes the following components in mass content:

[0091] Ba2Ti9O20 65wt%;

[0092] Mg2SiO4 20wt%;

[0093] Low melting point glass powder 15wt%;

[0094] Wherein, the low-melting point glass powder includes the following components by weight:

[0095]

[0096] Ba in this example 2 Ti 9 o 20 A method for preparing a low-temperature co-fired ceramic material comprising the steps of:

[0097] (1) According to the selected mass content ratio, weigh the corresponding weight of BaTiO 3 、TiO 2 , add water (material: water=1:1.3) and ammonium acrylate dispersant (accounting for 0.8wt% of the powder amount) and mix evenly, use a ball mill to pre-mix for 3h, and then use a horizontal sand mill (the grinding medium adopts 0.65 mm zirconium balls) to disperse to obtain a uniformly dispersed slurry;

[0098] (2) U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com