Polymer engineering plastic and preparation method thereof

A technology of engineering plastics and polymers, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of high cost, lack of preparation technology, lack of special equipment, etc., and achieve good wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

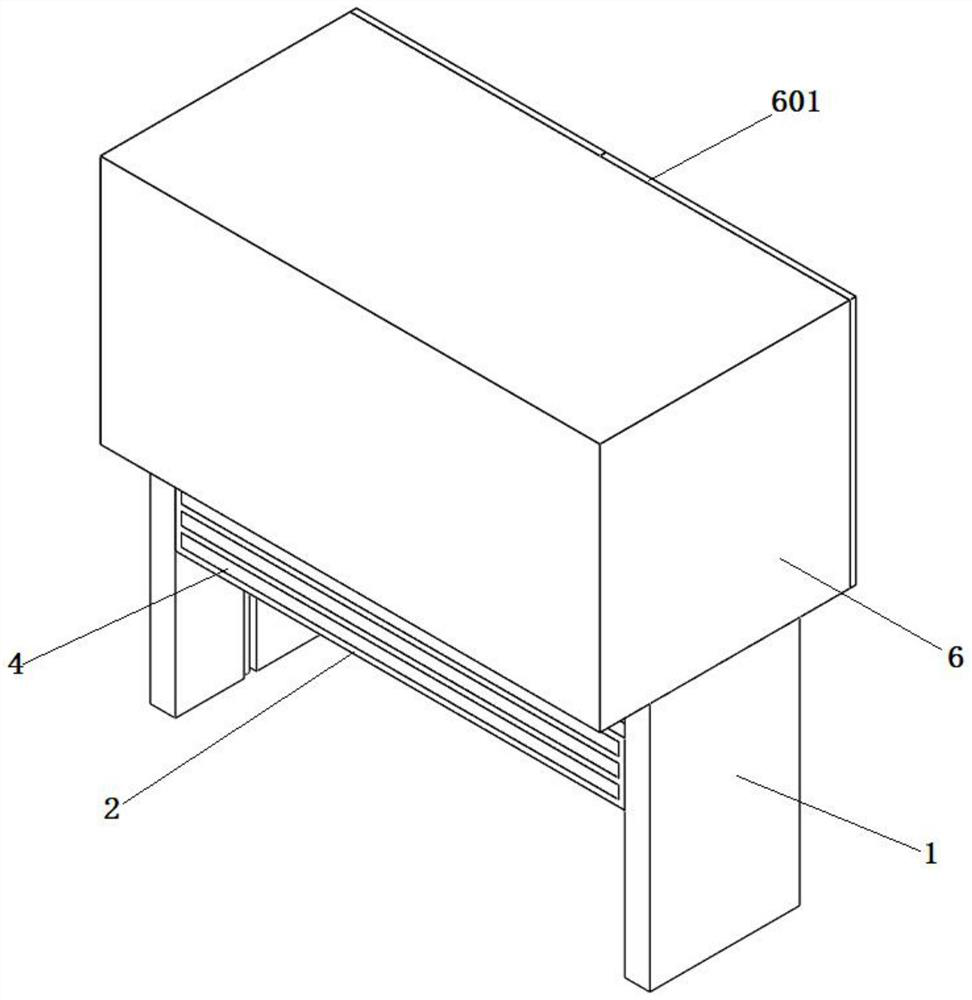

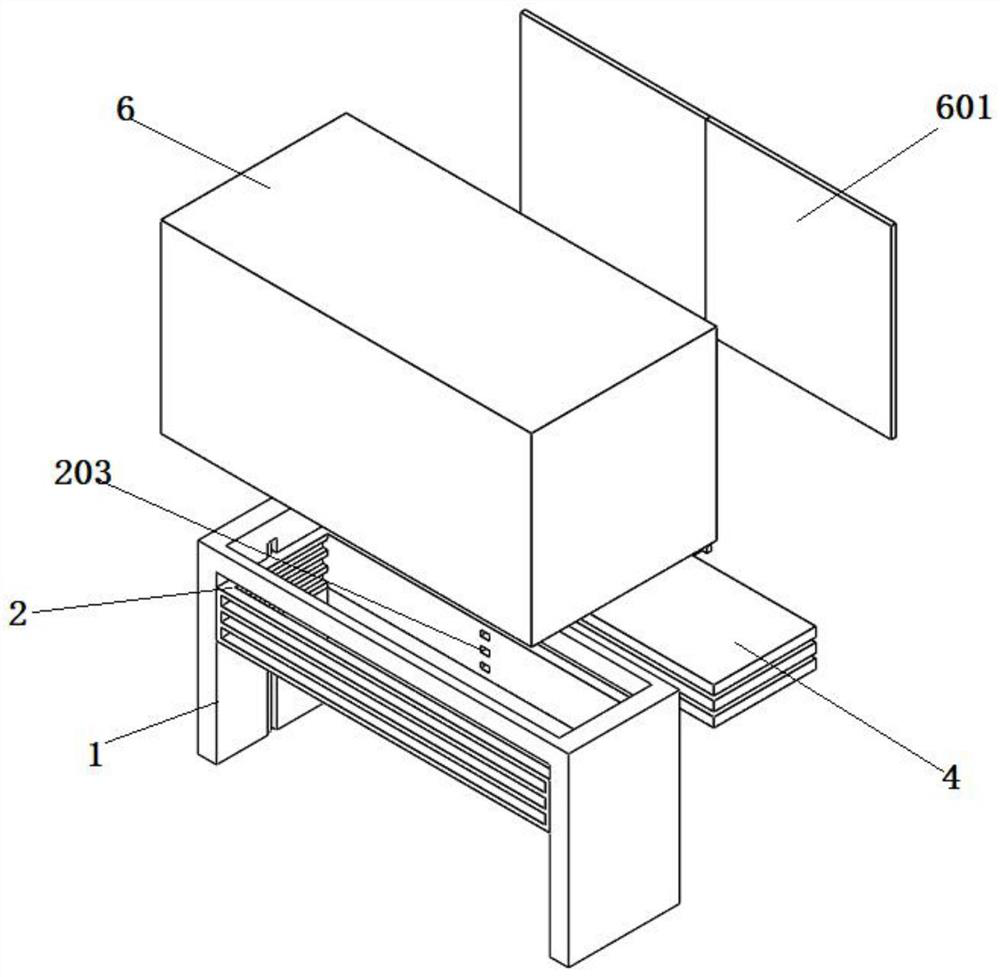

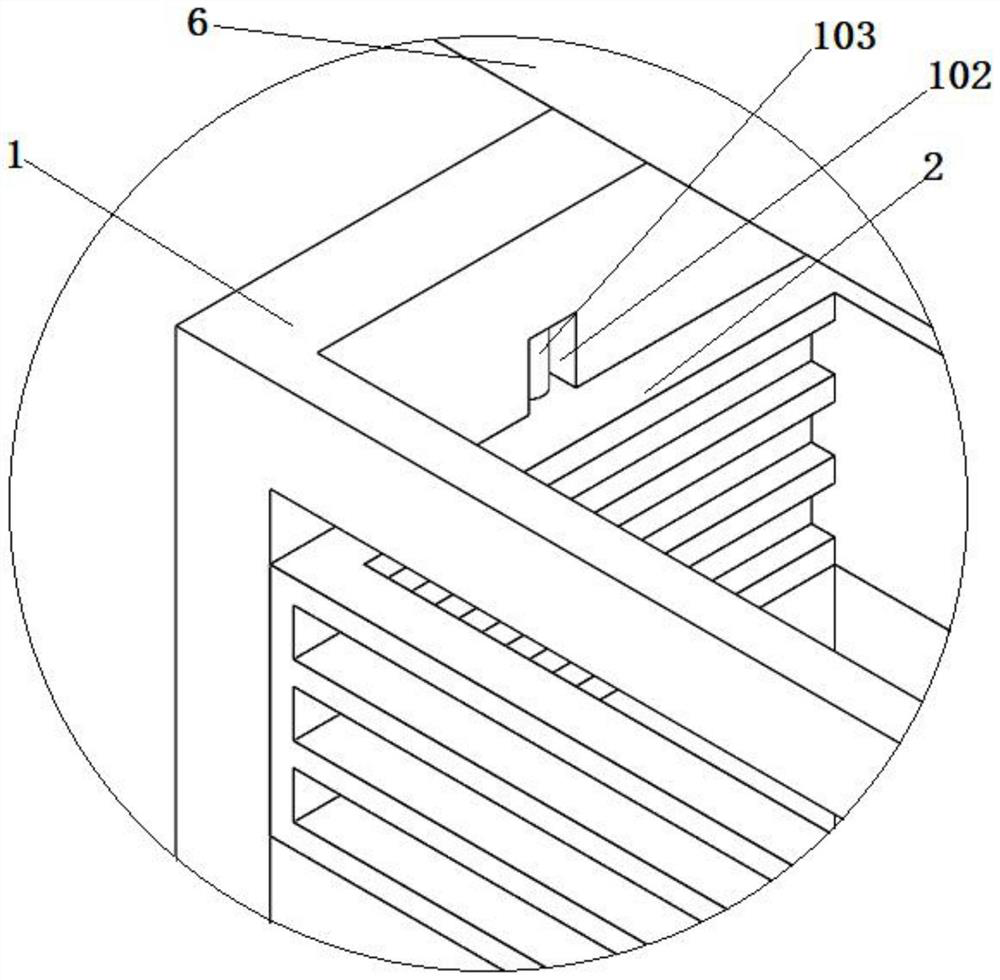

Image

Examples

Embodiment 1

[0050] A polymer engineering plastic, comprising the following raw materials by weight:

[0051] Raw material group 1: 50-57 parts of thermoplastics, 15-20 parts of polymer plastics, 2-3 parts of chain extender, 5-8 parts of polycarbonate, and 10-13 parts of nano-silica fume powder;

[0052] Raw material group 2: 2-5 parts of nano-magnesium hydroxide, 1-3.5 parts of flame retardant, 1-2 parts of glass fiber, 15-20 parts of crosslinking agent, 1-5 parts of plasticizer, 45-60 parts of phenolic plastic , 1 to 3 parts of nano titanium dioxide;

[0053] The engineering plastics are formed by hot-melting the two plastic layers prepared from the raw material group 1 and the raw material group 2.

Embodiment 2

[0055] A preparation method of polymer engineering plastics, comprising the following steps:

[0056] With the help of temperature control equipment, the temperature is controlled to a preset value, and the following reactions are carried out at the preset temperature;

[0057] Step 1: mixing the raw materials in the raw material group 1 to obtain a mixed material 1;

[0058] Step 2: adding the obtained mixed material 1 into the twin-screw machine, and cooling and granulating after melt extrusion;

[0059] Step 3: mixing the raw materials in the raw material group two to obtain a mixed material two;

[0060]Step 4: adding the obtained mixed material 2 into the twin-screw machine, and cooling and granulating after melt extrusion;

[0061] Step 5: two plastic layers are respectively obtained after granulating the raw material group 1 and the raw material group 2;

[0062] Step 6: Two plastic layers are formed into engineering plastics by hot melt welding;

[0063] The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com