Electro-catalysis nitrogen fixation device and method for simultaneously generating nitric acid and ammonia double products

A technology of nitric acid and nitrogen fixation, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of low ammonia yield, poor selectivity, high comprehensive cost, etc., achieve low energy consumption, increase yield and reaction rate, and adjustability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

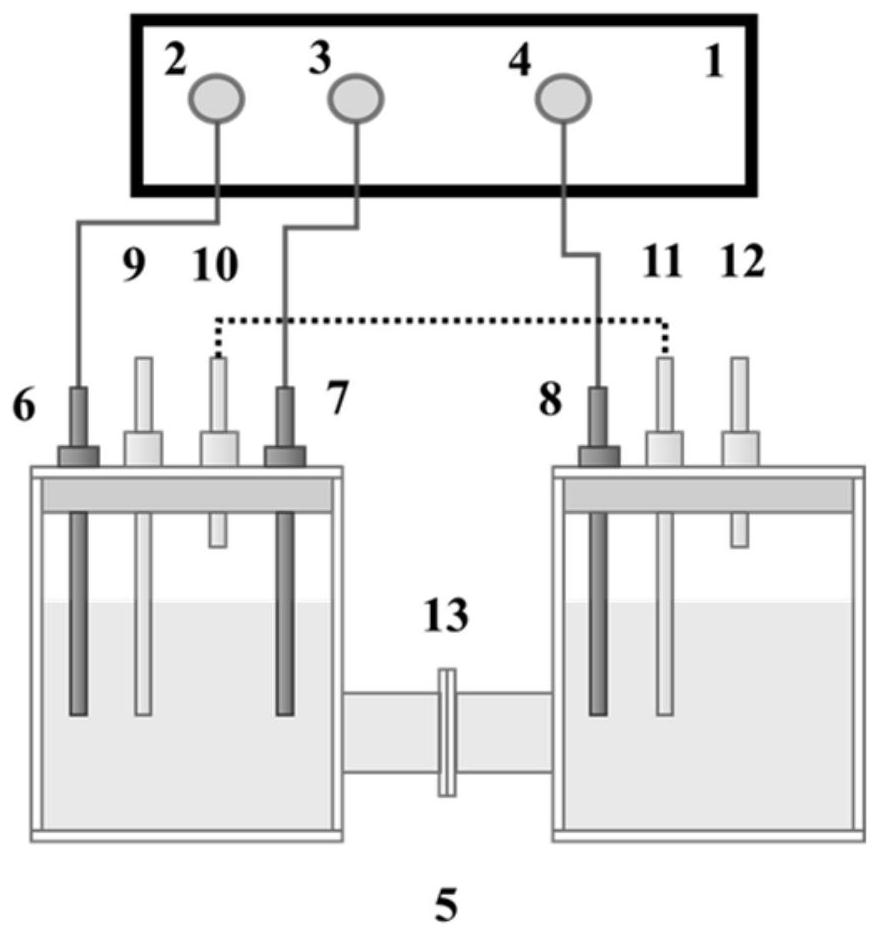

[0043] The surface of the single-sided carbon paper was uniformly covered with copper atoms by the method of magnetron sputtering, the sputtering thickness was 100 nm, and an argon atmosphere was used during sputtering. The carbon paper covered with copper was put into the electrodeposition electrolytic cell as the working electrode, and the electrolyte was 50ml of 0.05M dilute sulfuric acid, and 0.29g of cobalt nitrate hexahydrate and 0.29g of nickel nitrate hexahydrate were added, and the electrolytic solution was charged at a current of 0.2A. Deposit for 5min, rinse the impurities and electrolyte on the surface with deionized water, put it into a drying oven and dry to make the working electrode of the improved H-type electrolytic cell (5);

[0044] Take 60ml of 1M KOH solution into the cathode in the reaction vessel, take 60ml of 0.5M H 2 SO 4 The solution is put into the anode in the reaction vessel, separated by a bipolar membrane in the middle, the reaction vessel is p...

Embodiment 13-18

[0050] The surface of the single-sided carbon paper was uniformly covered with copper atoms by the method of magnetron sputtering, the sputtering thickness was 100 nm, and an argon atmosphere was used during sputtering. The carbon paper covered with copper is put into the electrodeposition electrolytic cell as the working electrode, and the electrolyte is 50ml of 0.05M dilute sulfuric acid, and a total of 0.02mol of cobalt nitrate and nickel nitrate of different proportions is added, and electrodeposited under the current of 0.2A. 5min, rinse the impurities and electrolyte on the surface with deionized water, put it into a drying box and dry to make the working electrode of the H-type electrolytic cell 6;

[0051] Take 60ml of 1M KOH solution into the cathode in the reaction vessel, take 60ml of 0.5M H 2 SO 4 The solution is put into the anode in the reaction vessel, separated by a bipolar membrane in the middle, the reaction vessel is placed on a magnetic stirrer, the rotati...

Embodiment 19-30

[0056] The surface of the single-sided carbon paper was uniformly covered with copper atoms by the method of magnetron sputtering, the sputtering thickness was 100 nm, and an argon atmosphere was used during sputtering. The carbon paper covered with copper was put into the electrodeposition electrolytic cell as the working electrode. The electrolyte was 50ml of 0.05M dilute sulfuric acid, 0.01mol of cobalt nitrate and 0.01mol of nickel nitrate were added, and the electrodeposition was carried out at a current of 0.2A for 5min. The impurities and electrolyte on the surface are washed with deionized water, put into a drying box and dried to make the working electrode of the H-type electrolytic cell 6;

[0057] The cathode and the anode in the reaction vessel are all added with 60ml of 1M KOH, the middle is separated by a proton exchange membrane, the reaction vessel is placed on a magnetic stirrer, the rotating speed is set to 200rpm, and the mass flow meter is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com