Electromagnetic braking device and method for controlling flowing of molten steel in tundish

An electromagnetic braking and tundish technology, applied in the field of steel continuous casting, can solve the problems of secondary pollution of molten steel and achieve the effects of slowing down the flow rate, increasing the floating time and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

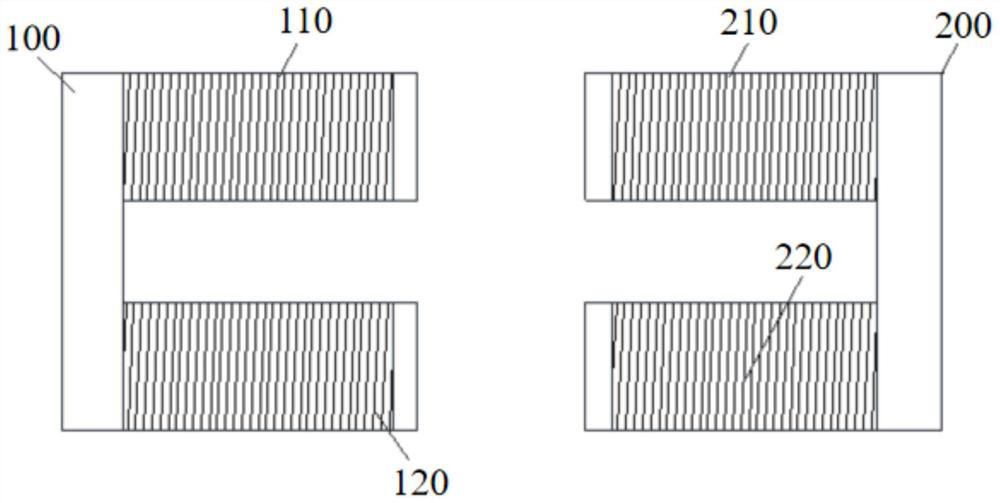

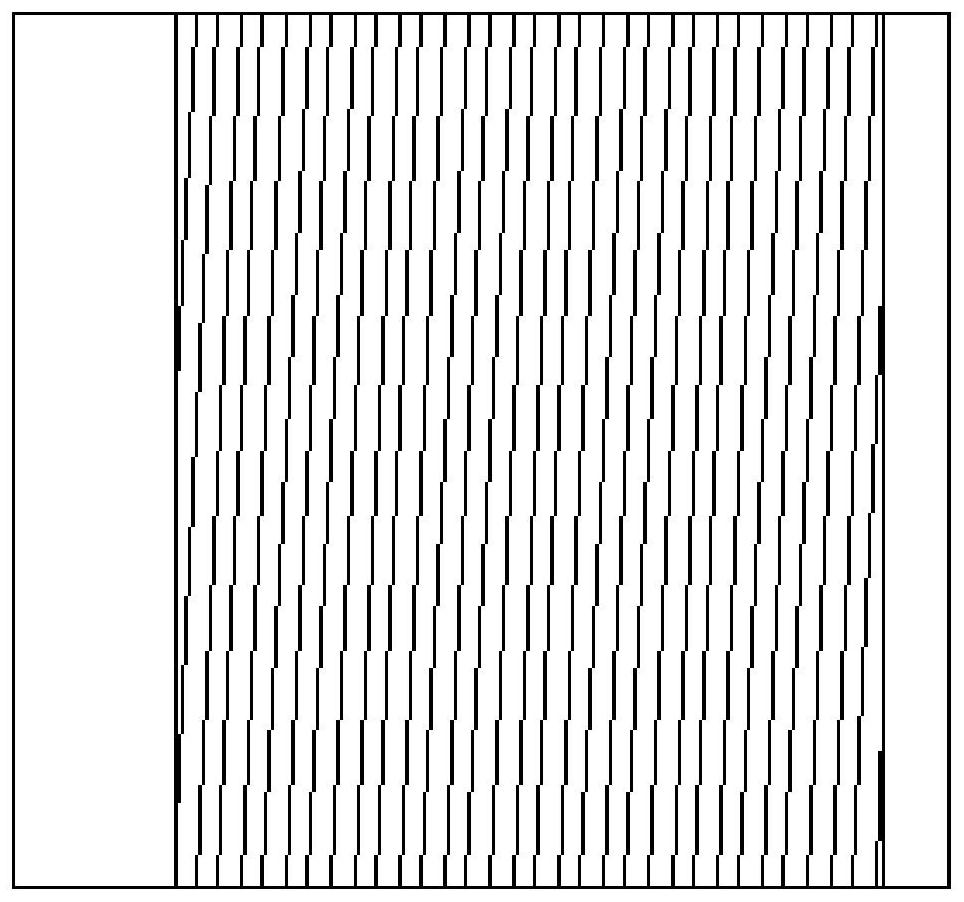

[0044] like figure 1 , figure 2 As shown, an electromagnetic braking device for controlling the flow of molten steel in a tundish according to this embodiment includes a first yoke 100, a second yoke 200, and the first yoke 100 and the second yoke 200 are arranged opposite to the middle On both sides of the package, the first yoke 100 and the second yoke 200 are wound with electromagnetic coils, and two magnetic fields are generated between the first yoke 100 and the second yoke 200, and the directions of the two magnetic fields are both directed from one side. On the other side, the two magnetic fields brake the molten steel in the tundish twice. The electromagnetic braking device of this embodiment does not directly contact the molten steel. Compared with the prior art, it will not cause secondary pollution of the molten steel due to the erosion and corrosion of the turbulence controller or refractory materials such as dams and weirs by the molten steel. , The device gene...

Embodiment 2

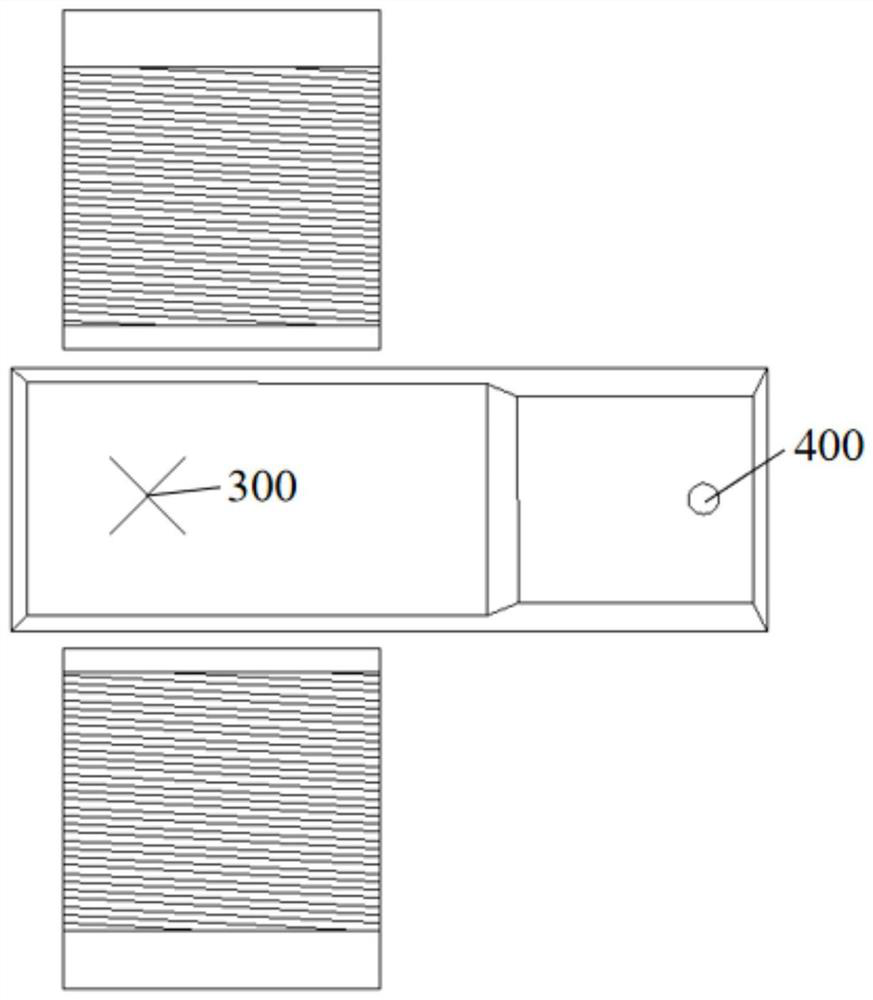

[0069] like image 3 , Figure 4 As shown, an electromagnetic braking device for controlling the flow of molten steel in the tundish according to this embodiment is arranged on both sides of the single-flow tundish as the electromagnetic braking device for the single-flow tundish. Specifically, the device is vertically installed on the front and rear sides of the tundish, and is placed facing the impact zone 300. The two magnetic field directions are both directed from one side to the other, and both are parallel to the bottom of the tundish, and the range is determined by the long nozzle ( That is, the molten steel starts from the position where the ladle flows into the inflow port of the tundish). Since the height of the yoke is higher than that of the single-flow tundish, when the molten steel is poured from the ladle to the single-flow tundish, the molten steel vertically passes through the upper magnetic field from top to bottom at high speed, and the bottom-up electroma...

Embodiment 3

[0072] like Figure 5 , Image 6 As shown, an electromagnetic braking device for controlling the flow of molten steel in the tundish according to this embodiment is arranged on both sides of the double-flow tundish as an electromagnetic braking device for the double-flow tundish. Specifically, the device is installed vertically on the front and rear sides of the tundish, and is placed facing the impact zone 300. The two magnetic field directions are both directed from one side to the other side, and both are parallel to the bottom of the tundish. Location is the center. Since the height of the yoke is higher than the double-flow tundish, when the molten steel is poured from the ladle to the double-flow tundish, the molten steel vertically passes through the upper magnetic field from top to bottom at a high speed, and the generated bottom-up electromagnetic force is applied to the molten steel. A deceleration is caused. After the molten steel reaches the impact zone 300, it f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com