Power type electrolyte and sodium ion battery

An electrolyte and power-based technology, which is applied in secondary batteries, hybrid capacitor electrolytes, secondary battery repair/maintenance, etc., can solve the problems that are not conducive to the desolvation of sodium ions, limit the work of sodium-ion batteries, and have high melting points of solvents. Achieve the effects of fast intercalation, excellent capacity retention, and low solvation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

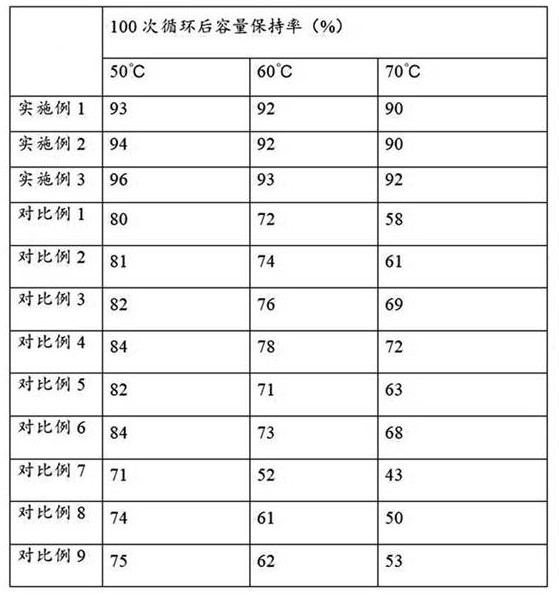

Examples

preparation example Construction

[0045] Wherein the preparation method of bentonite modifier is:

[0046] S11: Add 10-20 parts of bentonite to 25-35 parts of 5% hydrochloric acid solution by mass, then add 1-5 parts of silane coupling agent KH570, 1-3 parts of sodium alginate and 1-2 parts of lignosulfonic acid Sodium, stir and mix well to obtain bentonite liquid;

[0047] S12: placing the carbon nanotubes in a proton irradiation box for irradiation treatment, the irradiation power is 350-450W, the irradiation time is 10-20min, and the irradiation is completed to obtain irradiation-type carbon nanotubes;

[0048] S13: fully stir and disperse the irradiated carbon nanotubes and the bentonite liquid in a weight ratio of 1:5, then wash with water and dry;

[0049] S14: The product of S13 is calcined at 155-175° C. for 10-20 minutes, and then brought to room temperature at a rate of 1-3° C. / min.

[0050] The electrolyte salt of this embodiment is a mixed electrolyte of a sodium salt with a larger anion and othe...

Embodiment 1

[0069] The invention of this embodiment provides a power type electrolyte, an electrolyte salt, an organic solvent and a composite additive, wherein the electrolyte salt includes at least one weakly-coordinating anion sodium salt with a larger ionic radius and a bentonite modifier by weight It is compounded in a ratio of 3:1, and the compound additives include fluorocarbonate, sultone and modified alumina;

[0070] Wherein the preparation method of bentonite modifier is:

[0071] S11: add 10 parts of bentonite to 25 parts of hydrochloric acid solution with a mass fraction of 5%, then add 1 part of silane coupling agent KH570, 1 part of sodium alginate and 1 part of sodium lignosulfonate, stir and mix sufficiently to obtain bentonite liquid ;

[0072] S12: placing the carbon nanotubes in a proton irradiation box for irradiation treatment, the irradiation power is 350W, the irradiation time is 10min, and the irradiation is completed to obtain irradiation-type carbon nanotubes; ...

Embodiment 2

[0093] The invention of this embodiment provides a power type electrolyte, an electrolyte salt, an organic solvent and a composite additive, wherein the electrolyte salt includes at least one weakly-coordinating anion sodium salt with a larger ionic radius and a bentonite modifier by weight It is compounded in a ratio of 3:1, and the compound additives include fluorocarbonate, sultone and modified alumina;

[0094] Wherein the preparation method of bentonite modifier is:

[0095] S11: add 20 parts of bentonite to 35 parts of hydrochloric acid solution with a mass fraction of 5%, then add 5 parts of silane coupling agent KH570, 3 parts of sodium alginate and 2 parts of sodium lignosulfonate, stir and mix sufficiently to obtain bentonite liquid ;

[0096] S12: placing the carbon nanotubes in a proton irradiation box for irradiation treatment, the irradiation power is 450W, the irradiation time is 20min, and the irradiation is completed to obtain irradiated carbon nanotubes;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com