Injectable hydrogel adhesive capable of rapidly stopping bleeding as well as preparation method and application of injectable hydrogel adhesive

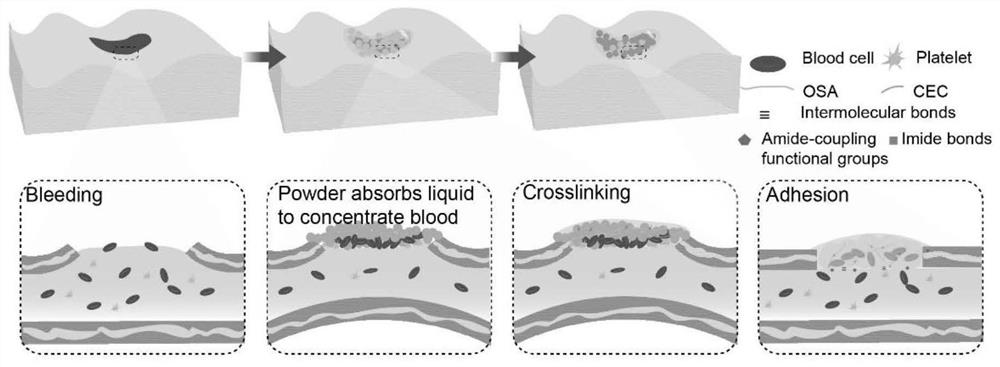

A hydrogel adhesive and hydrogel technology, applied in the fields of application, surgical adhesives, medical science, etc., can solve the problems of low strength and rapid disintegration of materials, so as to improve mechanical properties and maintain biocompatibility , the effect of preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

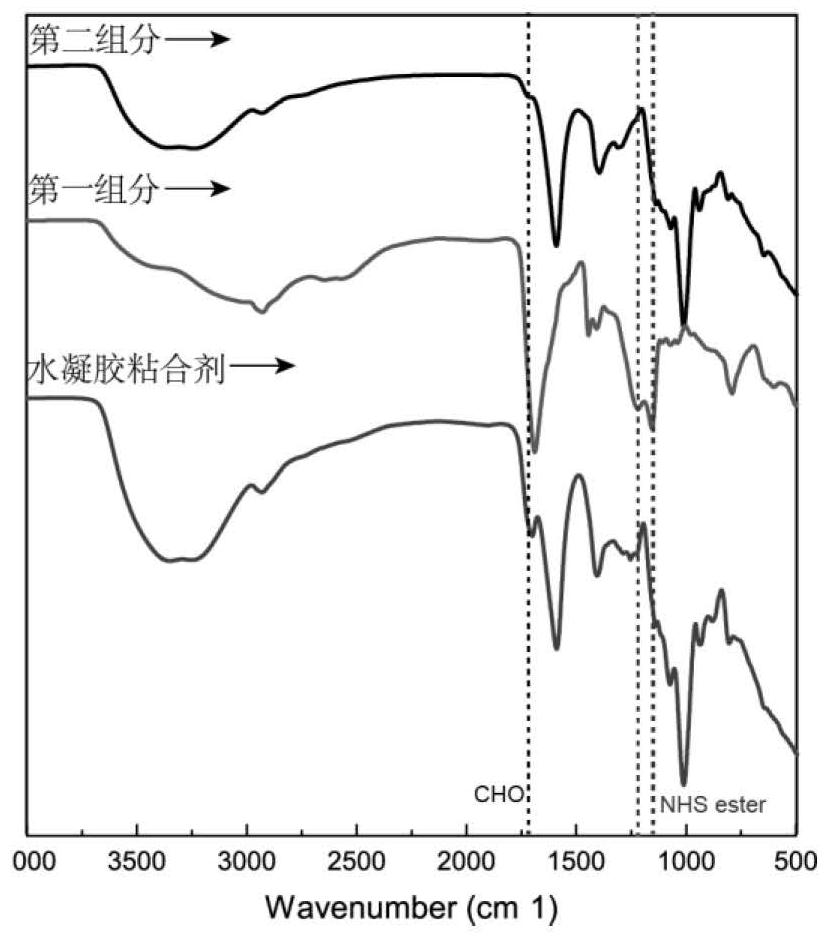

[0055] (1) At room temperature, dissolve 2 g of chitosan in 90 ml of water, and then add 10 g of acrylic acid for overnight.

[0056] (2) Take 20 g of the above solution, add 0.2 g of methacrylic anhydride gelatin, 0.2 g of α-ketoglutaric acid, and 0.2 g of N-acryloyloxysuccinimide, and stir until transparent.

[0057] (3) Pour into the mold of the acrylic plate and cross-link in the UV cross-linking box for 30min.

[0058] (4) Take out the sample and freeze-dry it with a vacuum freeze dryer.

[0059] (5) The lyophilized sample was put into a grinding jar at 50 Hz, and ground for 1 min to obtain the first component.

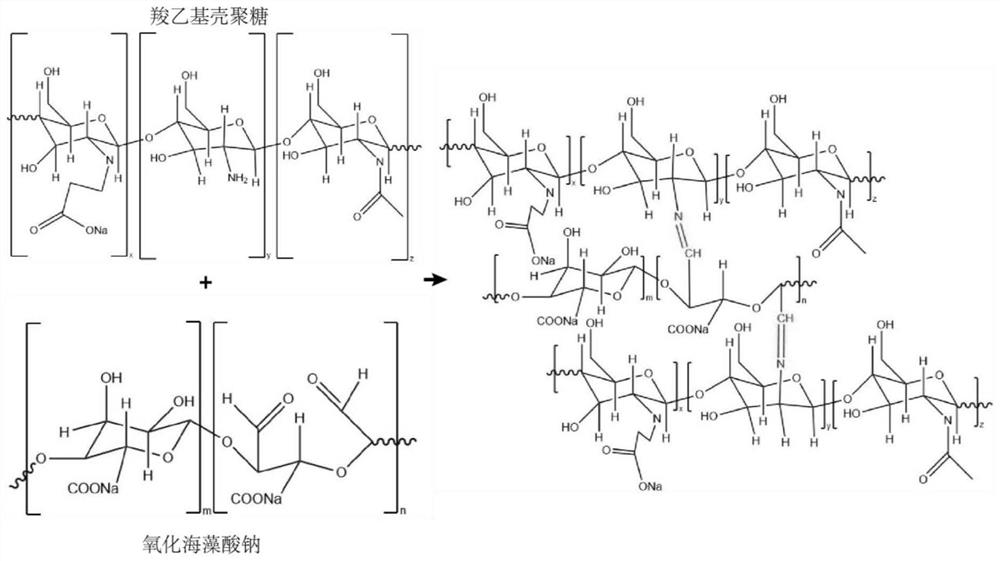

[0060] (6) Under normal temperature (of course, it can also be under other temperature conditions of 10-25°C), in 4wt% sodium alginate solution, add sodium periodate, and react in the dark for 12h; then add polyethylene glycol to react 2h, then dialyzed in deionized water, then dried, and then ground to obtain aldehyde group-terminated sodium alginate powder, n...

Embodiment 2

[0066] (1) At room temperature, dissolve 2g of carboxyethyl chitosan in 90ml of water, and then add 10g of acrylic acid for overnight.

[0067] (2) Take 20 g of the above solution, add 0.2 g of methacrylic anhydride gelatin, 0.2 g of α-ketoglutaric acid, and 0.2 g of N-acryloyloxysuccinimide, and stir until transparent.

[0068] (3) Pour into the mold of the acrylic plate and cross-link in the UV cross-linking box for 30min.

[0069] (4) Take out the sample and freeze-dry it with a vacuum freeze dryer.

[0070] (5) The lyophilized sample was put into a grinding jar at 50 Hz, and ground for 1 min to obtain the first component.

[0071] (6) At room temperature, in 4wt% sodium alginate solution, add sodium periodate, and react in the dark for 12 hours; then add polyethylene glycol for 2 hours, then dialyze in deionized water, then dry and grind again. An aldehyde group-terminated sodium alginate powder is obtained.

[0072] (7) Dissolving 20 g of oxidized sodium alginate in 80 g...

Embodiment 3

[0077] (1) At room temperature, dissolve 6g of chitosan in 60ml of water, and then add 40g of acrylic acid overnight.

[0078] (2) Take 20 g of the above solution, add 0.02 g of methacrylic acid anhydride gelatin, 0.1 g of α-ketoglutaric acid, and 0.2 g of N-acryloyloxysuccinimide, and stir until transparent.

[0079] (3) Pour into the mold of the acrylic plate and cross-link in the UV cross-linking box for 30min.

[0080] (4) Take out the sample and freeze-dry it with a vacuum freeze dryer.

[0081] (5) The lyophilized sample was put into a grinding jar at 50 Hz, and ground for 1 min to obtain the first component.

[0082] (6) At room temperature, in 4wt% sodium alginate solution, add sodium periodate, and react in the dark for 12 hours; then add polyethylene glycol for 2 hours, then dialyze in deionized water, then dry and grind again. An aldehyde group-terminated sodium alginate powder is obtained.

[0083] (7) Dissolving 20 g of oxidized sodium alginate in 80 g of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com