High-solid-content crystal combination porcelain feed and preparation method thereof

A technology of high solid content and crystal porcelain, which is applied in the appearance structural parts of crystal porcelain, high solid content composite crystal porcelain feeding and its preparation, can solve the problems of single color of the shell, small cutting amount, low strength, etc., and reduce the manufacturing cost. Low cost, good size processing, and low surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

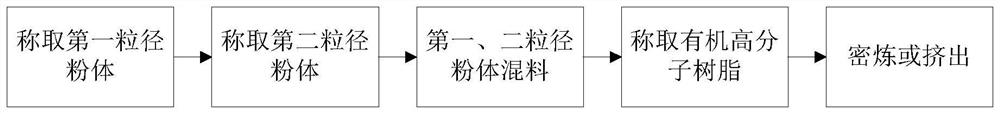

[0026] The invention discloses a preparation method of high solid content composite crystal ceramic feed, comprising the following steps:

[0027] a) Weigh parts by weight of 25-32.5 parts by weight of the inorganic powder of the first particle size, 25-32.5 parts by weight of the inorganic powder of the second particle size and 35-50 parts by weight of the organic polymer resin to obtain a mixed raw material ;

[0028] b) Banbury or extrude the mixed raw materials obtained in step a).

[0029] In this embodiment, the D50 of the inorganic powder with the first particle size selected in the above-mentioned preparation method of the high-solid content composite ceramic material is 0.7-1.8 μm, and the D50 of the inorganic powder with the second particle size is 0.1-1. 0.3 μm.

[0030] In the present embodiment, in the above-mentioned preparation method of high-solid content composite ceramic feedstock, the weight part of the inorganic powder with the first particle size is 28-3...

Embodiment 1

[0034] Feed preparation with a particle size ratio of 4.5

[0035] Weigh 2kg of zirconia inorganic powder with D50 of about 1.8μm, and then weigh 2kg of zirconia inorganic powder with D50 of about 0.4μm, and mix the two powders uniformly with a small solid mixer for later use.

[0036] Weigh 2.15kg of polyphenylene sulfide and add it to the mixer and heat it up to 310°C to melt it. Add the mixed powder to the mixer for several times, then close the mixer and evacuate to -0.06MPa at 310°C. After mixing for 1 hour, the temperature is lowered and the material is crushed to obtain the feed.

[0037] Melt index meter test Heat to 310 ℃, after heating 150g of the above-mentioned feed melt index meter, test under 2.16kg weight, the melt index is 0.91g / 10min.

Embodiment 2

[0039] Feed preparation with a particle size ratio of 20

[0040]Weigh 2kg of zirconia inorganic powder with D50 of about 1.8μm, and then weigh 2kg of zirconia inorganic powder with D50 of about 0.09μm, and mix the two powders uniformly with a small solid mixer for later use.

[0041] Weigh 2.15kg of polyphenylene sulfide and add it to the mixer and heat it up to 310°C to melt it. Add the mixed powder to the mixer for several times, then close the mixer and evacuate to -0.06MPa at 310°C. After mixing for 1 hour, the temperature is lowered and the material is crushed to obtain the feed.

[0042] Melt index meter test Heating to 310 ℃, after heating 150g of the above-mentioned feed melt index meter, test under 2.16kg weight, the melt index is 0.55g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com