Irradiation-resistant erbium-doped optical fiber preform rod based on fluorine-doped cladding and preparation method of irradiation-resistant erbium-doped optical fiber preform rod

An erbium-doped fiber, radiation-resistant technology, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems that the nano-particle doping technology cannot be realized, reduce the radiation sensitivity of the erbium-doped fiber, and the high content of co-dopants, and achieve Reduce background transmission loss, reduce radiation sensitivity, and maintain stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

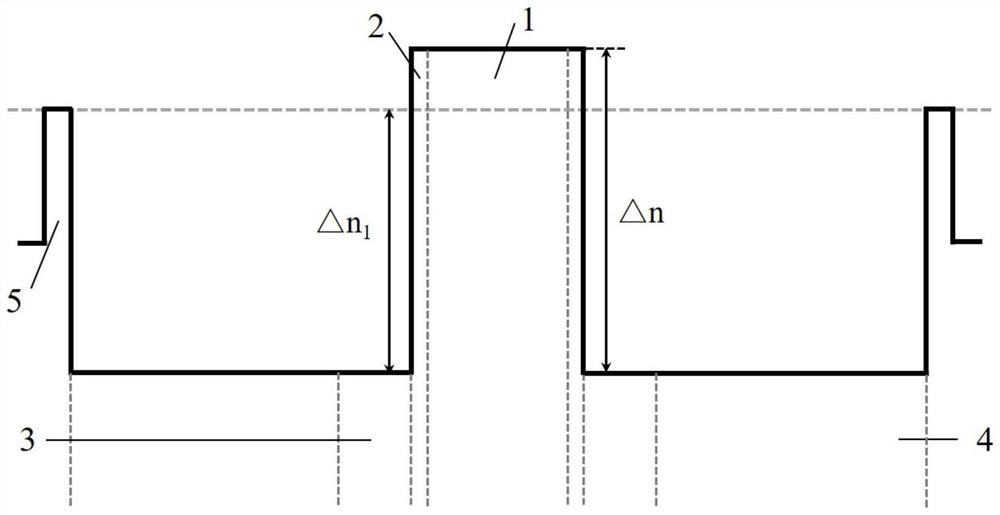

[0043] The germanium-fluorine co-doped quartz tube and the fluorine-doped quartz tube with a quartz layer on the outer surface were prepared by plasma chemical vapor deposition method. The germanium and fluorine co-doped quartz tubes are arranged from the inside to the outside as the transition layer 3 and the pure quartz layer, and the outer diameter ratio is 1:1.1. Layer 5, its outer diameter ratio is 1:1.15; the absolute refractive index of transition layer 3 and fluorine-doped quartz layer 4 are equal, and the relative refractive index difference between the two and pure quartz is Δn 1 Both are 0.015. Electron probe test results show that the composition and content of transition layer 3 are SiO 2 : 94.6Wt.%, GeO 2 : 1.3Wt.%, F: 4.1Wt.%; the composition and content of the fluorine-doped quartz layer 4 are SiO respectively 2 : 96.4Wt.%, F: 3.6Wt.%.

[0044] Using the above-mentioned germanium-fluorine co-doped silica tube as the deposition liner, the erbium-doped optica...

Embodiment 2

[0049] The deposition method of the erbium-doped optical fiber core rod, the size of the preform, the processing method of the sleeve, and the optical fiber structure are all the same as those in the first embodiment. The difference is the relative refractive index difference Δn between the transition layer 3 in the germanium-fluorine co-doped quartz tube, the fluorine-doped quartz layer 4 in the fluorine-doped quartz tube and the pure quartz layer 1 are 0.007; the deposition temperature is 1900°C, the rotational speed is 30rpm / min, the moving speed of the oxyhydrogen flame is 90mm / min, and the settings of the reaction materials are different when depositing the core area, as shown in Table 3. Electron probe test results show that the composition and average content of the central erbium-doped region 1 are SiO 2 : 95.0Wt.%, Er 2 O 3 : 1.2Wt.%, Al 2 O 3 : 2.3Wt.%, Ce 2 O 3 : 1.5Wt.%; the composition and average content of the non-erbium-doped region 2 are SiO 2 : 95.0Wt....

Embodiment 3

[0053] The deposition method of the erbium-doped optical fiber core rod, the sleeve processing method, and the optical fiber structure are all the same as those in the first embodiment. The difference is the relative refractive index difference Δn between the transition layer 3 in the germanium-fluorine co-doped quartz tube, the fluorine-doped quartz layer 4 in the fluorine-doped quartz tube and the pure quartz layer 1 All are 0.0142; the deposition temperature is 1750°C, the rotational speed is 30rpm / min, the moving speed of the oxyhydrogen flame is 100mm / min, and the settings of the reaction materials are different when depositing the core area, as shown in Table 4. Electron probe test results show that the composition and average content of the central erbium-doped region 1 are SiO 2 : 97.95Wt.%, Er 2 O 3 : 0.37Wt.%, Al 2 O 3 : 0.68Wt.%, Ce 2 O 3 : 1.0Wt.%; the composition and average content of the non-erbium-doped region 2 are SiO 2 : 97.5Wt.%, GeO 2 : 2.5Wt.%; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com