Gypsum-based plastering mortar composition

A technology for plastering mortar and composition, applied in the field of material preparation, can solve the problems of increased energy consumption and cost, high production cost, low thermal conductivity, etc., and achieves a low production cost, good construction performance and stable product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

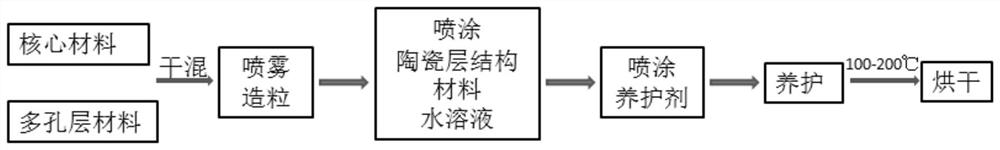

Method used

Image

Examples

Embodiment 1

[0090] This embodiment provides an aggregate comprising a core material, a porous layer material and a ceramic layer structure material;

[0091] The core material is walnut shell solid particles and / or corn flour solid particles;

[0092] The porous layer material includes the following components in parts by weight: 5 parts of cement, active components (30 parts of fly ash, 30 parts of active blast furnace slag, 10 parts of silica fume, 3 parts of kaolin), activator (3 parts of quicklime) parts, 1 part of gypsum), pelletizing agent (5 parts of polyvinyl alcohol, 2 parts of bentonite), dispersant (5 parts of sodium tripolyphosphate, 3 parts of polycarboxylate), 3 parts of xanthan gum, K 2 O 0.25 servings;

[0093] The ceramic layer structure material includes the following components in parts by weight: 55 parts of dead-burned MgO, 18 parts of ammonium dihydrogen phosphate, 20 parts of potassium dihydrogen phosphate, 1 part of borax, 5 parts of diammonium hydrogen phosphate,...

Embodiment 2

[0103] This embodiment provides an aggregate comprising a core material, a porous layer material and a ceramic layer structure material;

[0104] The core material is walnut shell solid particles and / or corn flour solid particles;

[0105] The porous layer material includes the following components in parts by weight: 5 parts of cement, active components (25 parts of fly ash, 30 parts of active blast furnace slag, 15 parts of silica fume, 3 parts of kaolin, and 0.5 parts of stone powder), excitation Agents (1 part of sodium sulfate, 1 part of sodium silicate, 1 part of quicklime, 1 part of triethanolamine), pelletizing agent (2 parts of polyvinyl alcohol, 2 parts of bentonite), dispersant (3 parts of sodium tripolyphosphate, polycarboxylate) acid 3 parts), 3 parts xanthan gum, K 2 O 0.25 servings;

[0106] The ceramic layer structure material includes the following components in parts by weight: 40 parts of dead-burned MgO, 40 parts of ammonium dihydrogen phosphate, 15 parts...

Embodiment 3

[0109] This embodiment provides an aggregate comprising a core material, a porous layer material and a ceramic layer structure material;

[0110] The core material is walnut shell solid particles and / or corn flour solid particles;

[0111] The porous layer material includes the following components in parts by weight: 7 parts of cement, active components (20 parts of fly ash, 30 parts of active blast furnace slag, 15 parts of silica fume, 4 parts of kaolin), activator (3 parts of quicklime) parts, 2 parts of gypsum), pelletizing agent (5 parts of polyvinyl alcohol, 2 parts of bentonite, 2 parts of polyethylene glycol, 2 parts of starch), dispersant (5 parts of sodium tripolyphosphate), 3 parts of xanthan gum, K 2 O 0.25 servings;

[0112] The ceramic layer structure material includes the following components in parts by weight: 45 parts of dead-burned MgO, 30 parts of ammonium dihydrogen phosphate, 15 parts of potassium dihydrogen phosphate, 2 parts of borax, 4 parts of diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com