Treatment method of silicon dioxide nanoparticles for blue-green fluorescent powder

A silicon dioxide and nanoparticle technology, applied in the fields of nanotechnology, chemical instruments and methods, and nanotechnology for materials and surface science, it can solve problems such as performance limitations and inability to make further breakthroughs, and achieve stable product performance and preparation. Less demanding timing requirements, the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

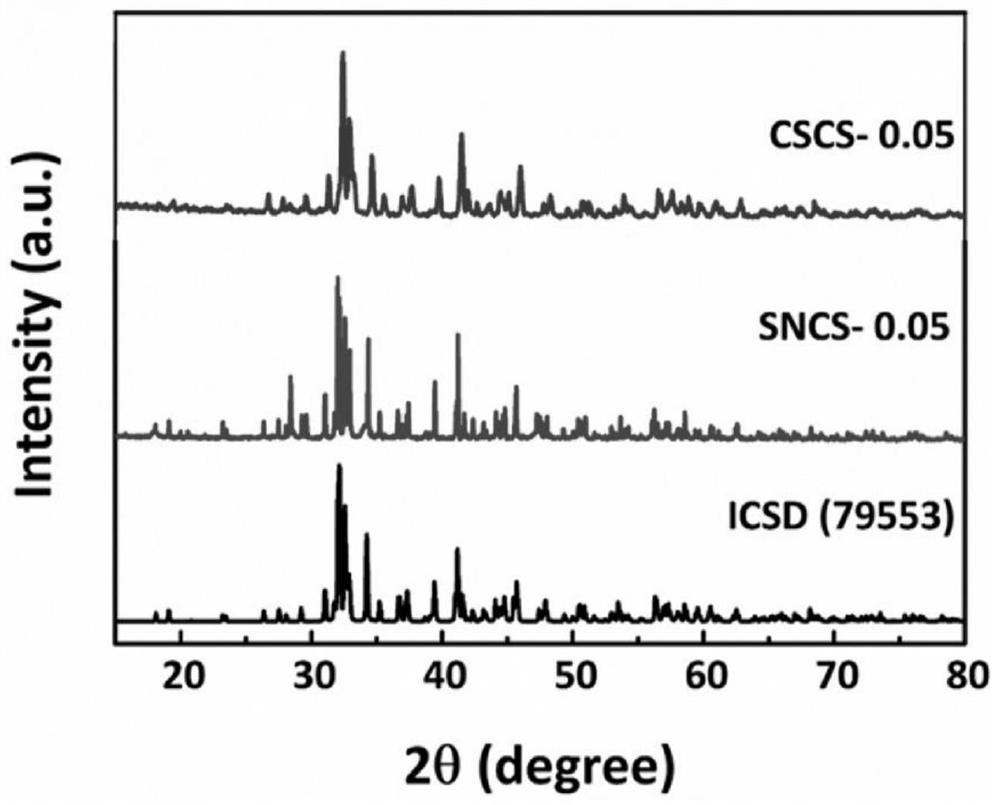

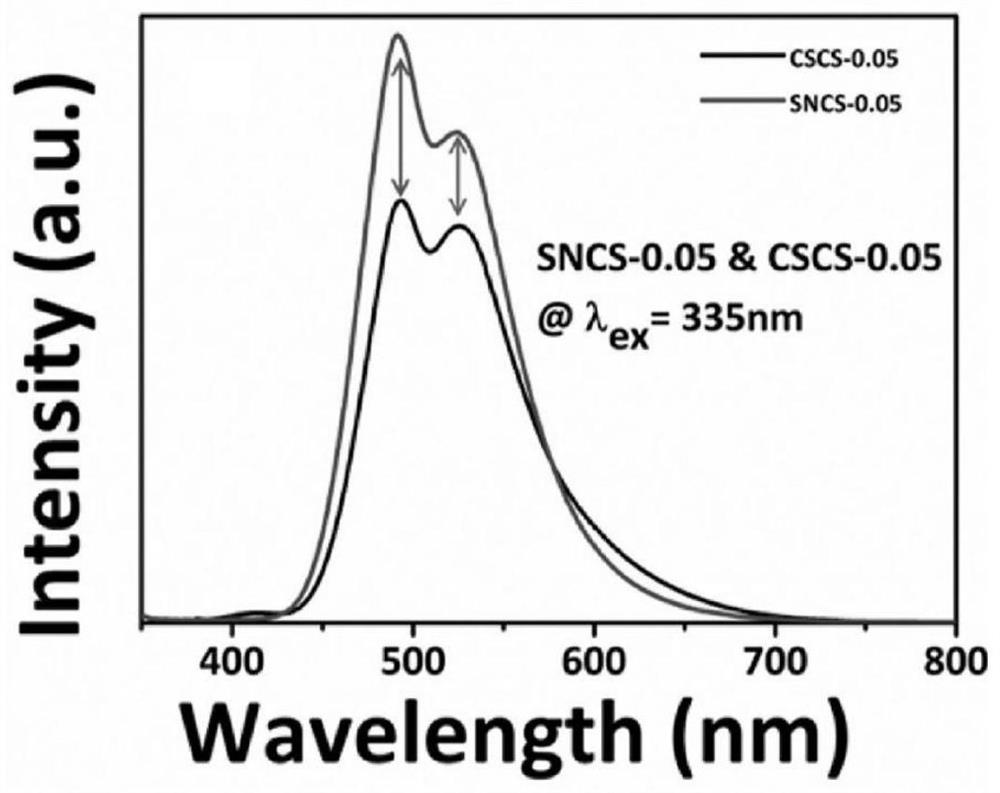

[0016] Example 1: Ca 2 SiO 4 : 0.05Eu 2+

[0017] Commercially available Ca 2 SiO 4 : Eu 2+ The phosphor powder was ground in acetone and calcined at 700° C. for 2 hours to obtain the blue-green phosphor.

Embodiment 2

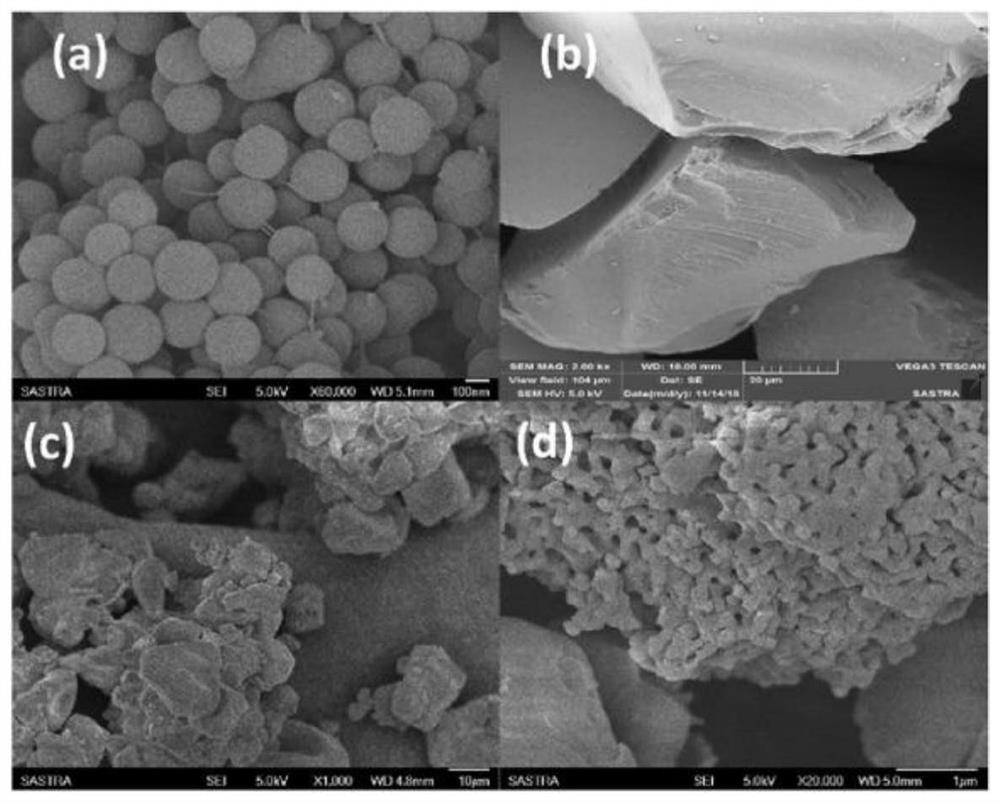

[0018] Example 2: 0.5SiO 2 -Ca 2 SiO 4 : 0.05Eu 2+

[0019] The treatment method of silica nanoparticles: commercially available polyvinylpyrrolidone (PVP) and absolute ethanol were stirred at room temperature at 200 rpm for 0.5 h at a volume ratio of 2 to obtain a mixed solution A. Then tetraethyl orthosilicate (TEOS) with a purity greater than 99.9% and ammonia water with a concentration of 5 mol / L were added to the mixed solution A to obtain a mixed solution B, wherein tetraethyl orthosilicate accounted for 10% of the mass of the mixed solution B. %. The mixed solution B was calcined at 200° C. for 2 hours to obtain powder particles. The particles are ground to obtain treated silica nanoparticles.

[0020] Preparation of phosphor powder: first, the treated silica particles were mixed with Ca 2 SiO 4 : Eu 2+ Mixed according to the mass ratio of 0.5, ground in acetone and calcined at 700° C. for 2 hours to obtain the blue-green fluorescent powder. Assuming that the ...

Embodiment 3

[0021] Example 3: 3SiO 2 -Ca 2 SiO 4 : 0.05Eu 2+

[0022] The treatment method of silica nanoparticles: commercially available polyvinylpyrrolidone (PVP) and absolute ethanol were stirred at room temperature at 300 rpm for 1 h at a volume ratio of 0.5 to obtain a mixed solution A. Then tetraethyl orthosilicate (TEOS) with a purity greater than 99.9% and ammonia water with a concentration of 0.5 mol / L are added to the mixed solution A to obtain a mixed solution B, wherein tetraethyl orthosilicate accounts for 2% of the mass of the mixed solution B. 20%. The mixed solution B was calcined at 100° C. for 4 hours to obtain powder particles. The particles are ground to obtain treated silica nanoparticles.

[0023] Preparation of phosphor powder: first, the treated silica particles were mixed with Ca 2 SiO 4 : Eu 2+ Mixed according to a mass ratio of 3, ground in acetone and calcined at 500° C. for 4 hours to obtain the blue-green fluorescent powder. Assuming that the lumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com