Coked wax oil purification device and method

A technology of coking wax oil and coke powder, which is applied in the field of coking wax oil purification equipment, can solve the problems of high maintenance cost, catalyst deactivation, and high equipment purchase cost, and achieve stable product performance, high filtration accuracy, and low operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

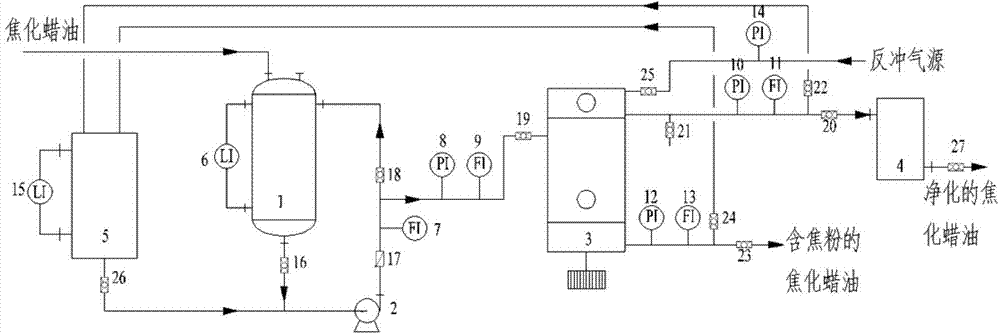

[0027] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0028] figure 1 It is a schematic diagram of the overall structure of the present invention, such as figure 1 Shown: The device for purifying coker wax oil provided by the present invention includes a storage tank 1 , a feed pump 2 , a ceramic disc membrane filter 3 , a product storage tank 4 and a cleaning tank 5 .

[0029] The storage tank 1 and the ceramic disc membrane filter 3 are connected together through pipelines, and a feed pump 2 is installed on the pipeline between the storage tank 1 and the ceramic disc membrane filter 3; A storage tank outlet valve 16 is installed on one section of the pipeline, and a feed pump check valve 17, a feed pump flow meter 7, and an inlet ceramic disc membrane filter 3 are sequentially installed on the pipeline from the feed pump 2 to the ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com