Water-dispersible polyisocyanate curing agent as well as preparation method and application thereof

A polyisocyanate and diisocyanate technology, applied in the field of polyurethane, can solve the problems of effective functional group content, water resistance and strength performance, and no further description of the industrial practicability and influence of water-based TDI curing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

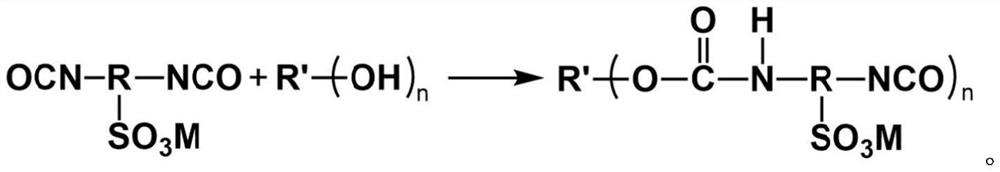

Method used

Image

Examples

Embodiment 1

[0086] The present embodiment has prepared a water-dispersible polyisocyanate curing agent, and the steps are:

[0087] A1. Preparation of sulfonate modified diisocyanate (TDI) prepolymer:

[0088] In the No. 1 reaction flask, add 400g (4.598 equivalents) of TDI, turn on the stirrer, heat up to 30°C, take 352g (1.532 equivalents) of small-molecule sulfonate diol, add it in six times, and react 0.5 times after each addition. h, until all the additions are completed, after 1h of reaction, the temperature is first heated to 50°C for 2h, then heated to 60°C for 5h, and then samples are taken every 0.5h to measure the -NCO content. , to obtain sulfonate-modified diisocyanate (TDI) prepolymer.

[0089] The viscosity of the sulfonate-modified diisocyanate (TDI) prepolymer was tested to be 4200 mPa.s / 25°C, and the NCO% was 17.1%.

[0090] A2. Preparation of sulfonate modified multifunctional internal emulsifier:

[0091] In the No. 2 reaction flask, add 200 g (0.814 equivalent) of ...

Embodiment 2

[0097] The present embodiment has prepared a water-dispersible polyisocyanate curing agent, and the steps are:

[0098] a) Preparation of sulfonate modified multifunctional internal emulsifier:

[0099] In the No. 1 reaction flask, add 200g (0.814 equivalent) of the sulfonate-modified diisocyanate (TDI) prepolymer prepared in step A1 of Example 1 and 70g of propylene glycol monomethyl ether acetate (hydrophilic solvent), turn on the stirrer , heat up to 50°C, add 9.1g (0.2035 equivalents) of trimethylolpropane (small molecule polyol), react without heating for 1h, heat up to 60°C for 2h, then heat up to 80~85°C for 4h and measure the reactant When the -NCO content of -NCO decreased and became stable, the reaction was stopped; the residual TDI monomer was removed, the temperature of the material was reduced to 60 °C, 70 g of propylene glycol methyl ether acetate was added, and the material was discharged to obtain a sulfonate modified polyfunctional Internal emulsifier.

[01...

Embodiment 3

[0105] The present embodiment has prepared a water-dispersible polyisocyanate curing agent, and the steps are:

[0106] In the reaction flask, add 250g of polyisocyanate prepolymer 2, turn on the stirrer, then add 50g of the multifunctional internal emulsifier obtained in step A2 of Example 1, heat up to 85°C, mix and react for 2h, cool down to 60°C, add 15g of cyclohexane, 15g of 200# gasoline and 6g of Siloke 4600 defoamer, stir evenly, and discharge to obtain a water-dispersible polyisocyanate curing agent.

[0107] After testing, the solid content of the curing agent is 67%, the viscosity is 1100 mPa·s / 25°C, the NCO% is 11.0%, and the residual TDI is 0.28%.

[0108] Pour 100 g of the water-dispersible polyisocyanate curing agent obtained in this example into 100 g of distilled water under stirring, and stir at a rotational speed of 400 rpm for 20 min to obtain a milky white blue light emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com