Aluminum alloy door/window scratch repair putty and preparation method thereof

A technology of aluminum alloy doors and windows and putty, which is applied in the direction of filling slurry, etc., can solve the problems of difficult metal surface repair, short material activation period, poor metal surface adhesion, etc., and achieve good construction performance, good filling performance, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

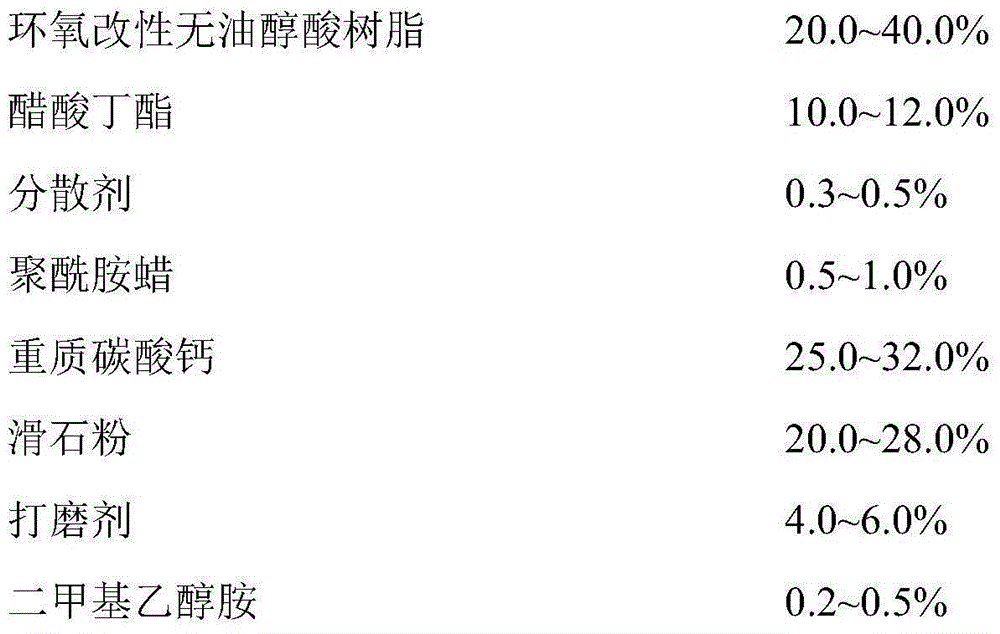

[0026] A component is made up of following components among the present embodiment:

[0027]

[0028]

[0029] The above percentages are mass percentages;

[0030] Component B is hexamethylene diisocyanate (HDI)-toluene diisocyanate (TDI) mixed trimer.

[0031] A preparation method of putty for repairing scratches on aluminum alloy doors and windows, said preparation method comprising the following preparation steps:

[0032] Put the epoxy-modified oil-free alkyd resin, butyl acetate and dispersant in component A into the paint-making tank, add polyamide wax at a stirring speed of 1200rpm / min and keep stirring for 30 minutes, and then add it to the paint-making tank in turn. Put heavy calcium carbonate, talcum powder and abrasive into the cylinder, disperse at a high speed at a speed of 2500rpm / min until the fineness is less than or equal to 50μm, then put in dimethylethanolamine, and stir evenly;

[0033] The B component is a mixed trimer of hexamethylene diisocyanate...

Embodiment 2

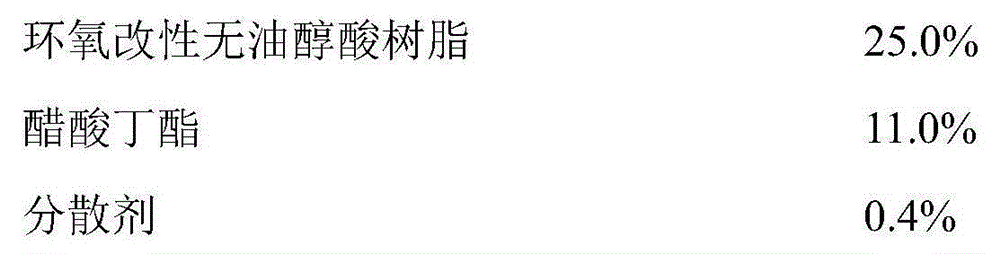

[0036] A component is made up of following components among the present embodiment:

[0037]

[0038] The above percentages are mass percentages;

[0039] Component B is hexamethylene diisocyanate (HDI)-toluene diisocyanate (TDI) mixed trimer.

[0040] A preparation method of putty for repairing scratches on aluminum alloy doors and windows, said preparation method comprising the following preparation steps:

[0041] Put the epoxy-modified oil-free alkyd resin, butyl acetate and dispersant in component A into the paint-making tank, add polyamide wax at a stirring speed of 1200rpm / min and keep stirring for 30 minutes, and then add it to the paint-making tank in turn. Put heavy calcium carbonate,

[0042] Talc powder and grinding agent are dispersed at a high speed at a speed of 2500rpm / min until the fineness is less than or equal to 50μm, and then dimethylethanolamine is added and stirred evenly;

[0043] The B component is a mixed trimer of hexamethylene diisocyanate (HD...

Embodiment 3

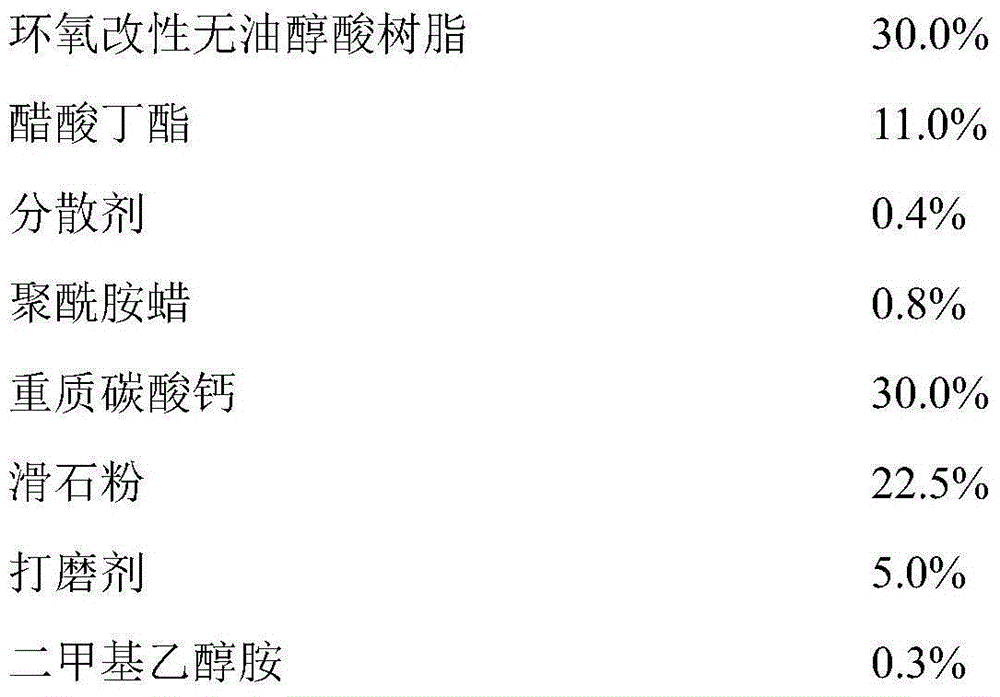

[0046] A component is made up of following components among the present embodiment:

[0047]

[0048] The above percentages are mass percentages;

[0049] Component B is hexamethylene diisocyanate (HDI)-toluene diisocyanate (TDI) mixed trimer.

[0050] A preparation method of putty for repairing scratches on aluminum alloy doors and windows, said preparation method comprising the following preparation steps:

[0051] Put the epoxy-modified oil-free alkyd resin, butyl acetate and dispersant in component A into the paint-making tank, add polyamide wax at a stirring speed of 1200rpm / min and keep stirring for 30 minutes, and then add it to the paint-making tank in turn. Put heavy calcium carbonate, talcum powder and abrasive into the cylinder, disperse at a high speed at a speed of 2500rpm / min until the fineness is less than or equal to 50μm, then put in dimethylethanolamine, and stir evenly;

[0052] The B component is a mixed trimer of hexamethylene diisocyanate (HDI)-tolue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com