Preparation method of automotive topcoat composite coating capable of being rapidly cured and long in activation period

A car topcoat, rapid curing technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problem that the car topcoat cannot be applied, the comprehensive requirements of construction technology and paint film performance cannot be met at the same time, and the pot life is short and other problems, to achieve the effect of strong practicability, prolonging the activation period and long activation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] At a temperature of 8°C and a humidity of 50%RH, a method for preparing a composite coating of an automotive topcoat that can be cured quickly and has a long pot life, comprises the following steps:

[0029] (1) Spray a 1k base coat on the surface of the car without chemical crosslinking reaction, and let it dry for 5-10 minutes to form a 1k base coat layer;

[0030] (2) Spraying a 1k transparent accelerator coating containing 0.5%-1wt% drier without chemical crosslinking reaction on the 1k base paint, and drying on the surface for 5-10 minutes to form a 1k transparent accelerator paint layer;

[0031] (3) Spray the 2k finish varnish that does not contain drier with chemical crosslinking reaction on described 1k transparent promotion paint, and the drier in described 1k transparent promotion paint is to 1k base color paint layer and 2k cover varnish. Osmotic migration in the varnish coating to form a 2k varnish layer and promote rapid curing of the varnish.

[0032] Th...

Embodiment 2

[0052] The preparation method and the coating thereof of the fast-curing and long pot life automotive topcoat composite coating provided in this embodiment, its basic steps are the same as those in Example 1, except that:

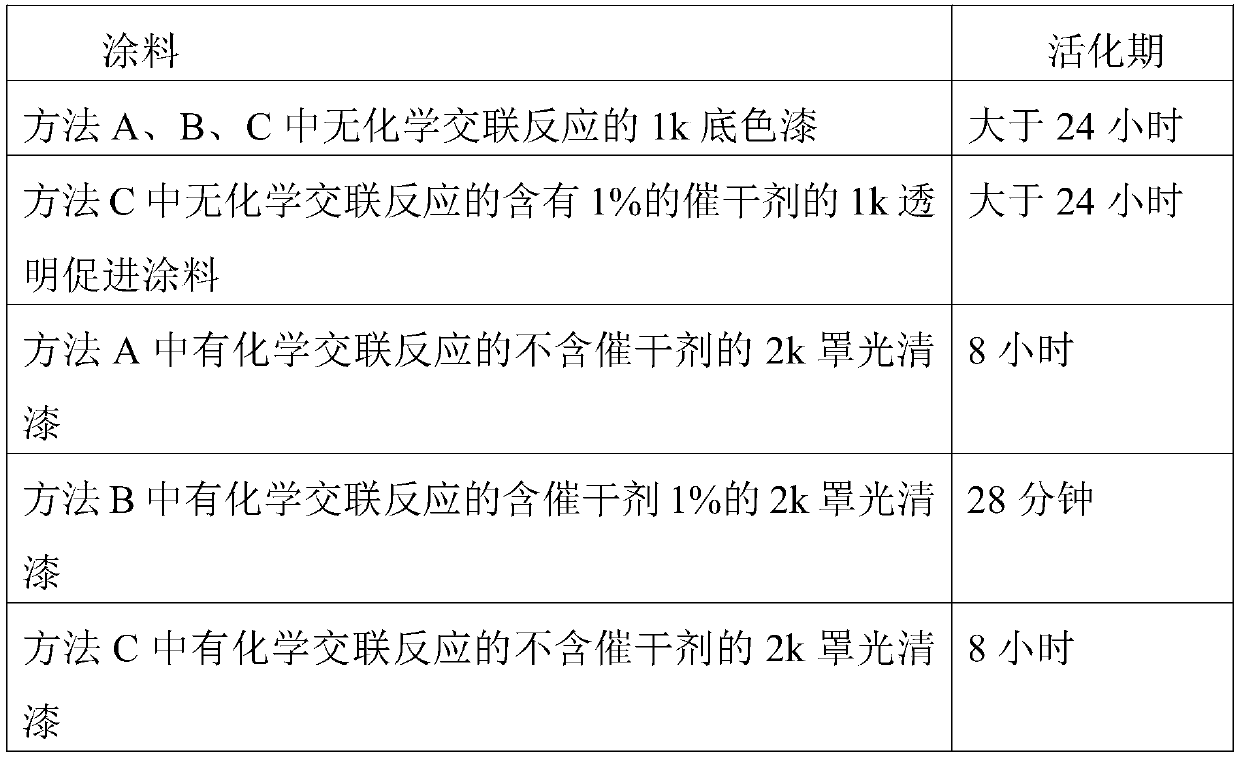

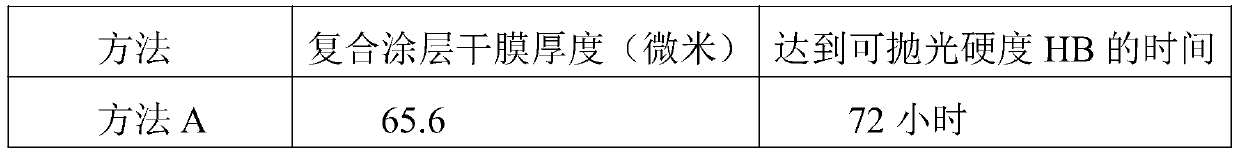

[0053] When the temperature is 25°C and the humidity is 40%RH, three methods are used for construction.

[0054] Method A: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and then spray a 2k finish varnish with chemical crosslinking reaction without drier;

[0055] Method B: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and spray a 2k finish varnish with chemical crosslinking reaction containing 1% drier;

[0056] Method C: Spray 1k base paint without chemical crosslinking reaction, surface dry for 5 minutes, spray 1k transparent accelerator coating containing 1% drier without chemical crosslinking reaction, surface dry for 5 minutes, spray with chemical crosslinking Reactive 2k varn...

Embodiment 3

[0063] The preparation method and the coating thereof of the fast-curing and long pot life automotive topcoat composite coating provided in this embodiment, its basic steps are the same as those in Example 1, except that:

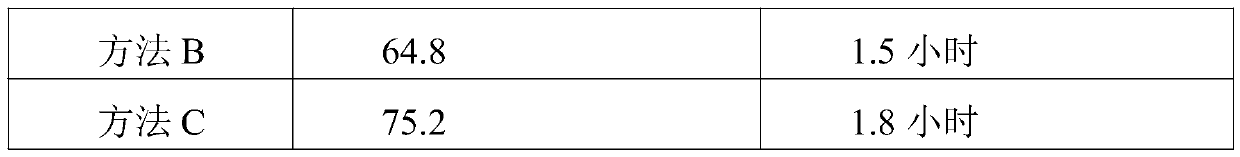

[0064] When the temperature is 35°C and the humidity is 30%RH, three methods are used for construction.

[0065] Method A: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and then spray a 2k finish varnish with chemical crosslinking reaction without drier;

[0066] Method B: Spray a 1k primer without chemical crosslinking reaction, let it dry for 5 minutes, and spray a 2k finish varnish with chemical crosslinking reaction containing 1% drier;

[0067] Method C: Spray 1k base paint without chemical crosslinking reaction, surface dry for 5 minutes, spray 1k transparent accelerator coating containing 1% drier without chemical crosslinking reaction, surface dry for 5 minutes, spray with chemical crosslinking Reactive 2k varn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com