Liquid fermentation culture medium of brevibacterium friariorum SDB5

A cold-resistant Brevibacterium, liquid fermentation technology, applied in bacteria, microorganism-based methods, microorganisms, etc., can solve the problems of lack of organic matter, medium/trace elements, high production cost, low fermentation density, etc., to improve nutrient utilization efficiency, The effect of shortening the fermentation cycle and promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Medium optimization of Brevibacterium hardy SDB5

[0019] The yeast extract was replaced with yeast paste, and NaCl was replaced with pickled coarse salt (the main component was sodium chloride). On this basis, a single-factor replacement experiment was performed. In this experiment, LB medium was used as the control group, and its components were: 10g / L tryptone, 5g / L yeast extract, 10g / L NaCl.

[0020] 1.1 Single factor influence

[0021] (1) Experiment of pickling coarse salt instead of analytically pure sodium chloride

[0022] Experimental group: peptone medium: 10g / L peptone, 5g / L yeast extract, 10g / L coarse salt. The bacterial culture conditions were the same. Using a spectrophotometer to measure the OD of the bacterial liquid at different incubation times 600 The value of bacteria was measured, and the bacterial content in the bacterial liquid was detected to judge the growth of bacteria. The experimental results are shown in Table 1.

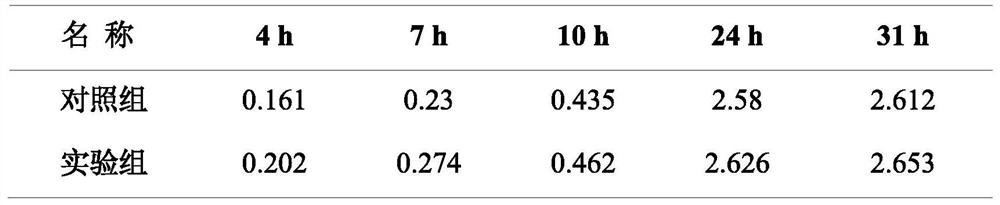

[0023] Ta...

Embodiment 2

[0045] Example 2: Sodium chloride removal experiment

[0046] Coarse salts were removed from the medium most suitable for SDB5 bacteria, and inorganic salts were directly added for comparative experiments, as shown in Table 7. The control group is LB medium (numbered 4), and the results are shown in the results table of the plate counting experiment, as shown in Table 8. It can be seen from Table 8 that NaCl has a significant impact on SDB5 bacteria and cannot be directly replaced by inorganic salts, otherwise the growth ability of the strain will be weakened, thereby reducing the bacterial content in the fermentation broth.

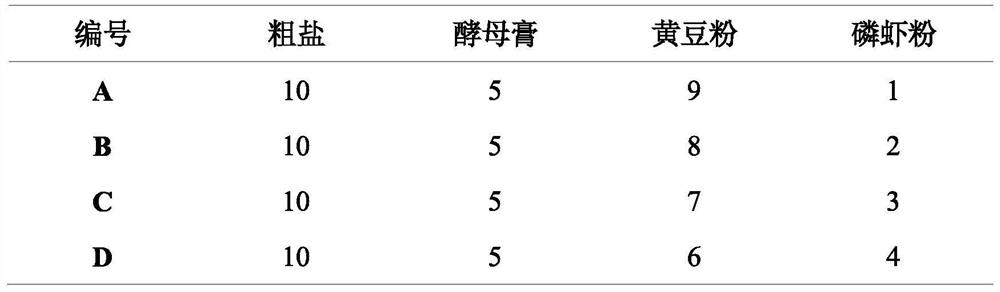

[0047] Table 7 Plate Counting Experiment Design Table (unit: g / L)

[0048]

[0049] Table 8 Plate Counting Experiment Results Table

[0050]

Embodiment 3

[0051] Example 3: Optimal medium composition and plate count experiment

[0052] Based on the above experimental results, it can be seen that the most suitable special low-cost high-density liquid fermentation medium for Brevibacterium cold-resistant SDB5 is: 8g / L soybean meal, 2g / L krill meal, 5g / L yeast extract, 10g / L pickled Coarse salt, 1.8g / L MgSO 4 , 1.8g / L K 2 HPO 4 and 1.2g / L CaCO 3 . Fermentation experiments were carried out using this medium, and the control group was LB medium, and the fermentation conditions were the same. The results showed that the viable bacteria content of Brevibacterium cold resistant SDB5 in the fermentation broth of the control group was 0.8×10 8 CFU / mL, while the viable bacterial content of Brevibacterium cold-resistant SDB5 in the fermentation broth of the optimal medium was 3.42×10 8 CFU / mL, the fermentation effect of the optimal medium was about 4.3 times higher than that of the control group, and the effect was good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com