Preparation method of chalcone-terminated photosensitive waterborne polyurethane/epoxy acrylate

A technology of epoxy acrylate and waterborne polyurethane, applied in polyurea/polyurethane coatings, epoxy resin coatings, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] According to a preferred embodiment of the present invention, the raw material further includes a water-based chain extender, and the water-based chain extender is a substance that introduces an ionic group or a group that can be ionized when the prepolymer performs chain extension.

[0036] The water-based chain extender is selected from one or more of sulfonate type chain extenders, preferably selected from dimethylol propionic acid, dimethylol butyric acid, dimethylolvaleric acid and dimethylol One or more of hexanoic acid, more preferably dimethylolpropionic acid with a hydrophilic carboxyl group.

[0037] Based on 30 parts by weight of polyisocyanate, the amount of the aqueous chain extender is 4-8 parts by weight, preferably 4.5-7 parts by weight, more preferably 5-6 parts by weight.

[0038] The raw material also includes a neutralizing agent, and the neutralizing agent is selected from one or more of organic bases, preferably selected from diethanolamine, trieth...

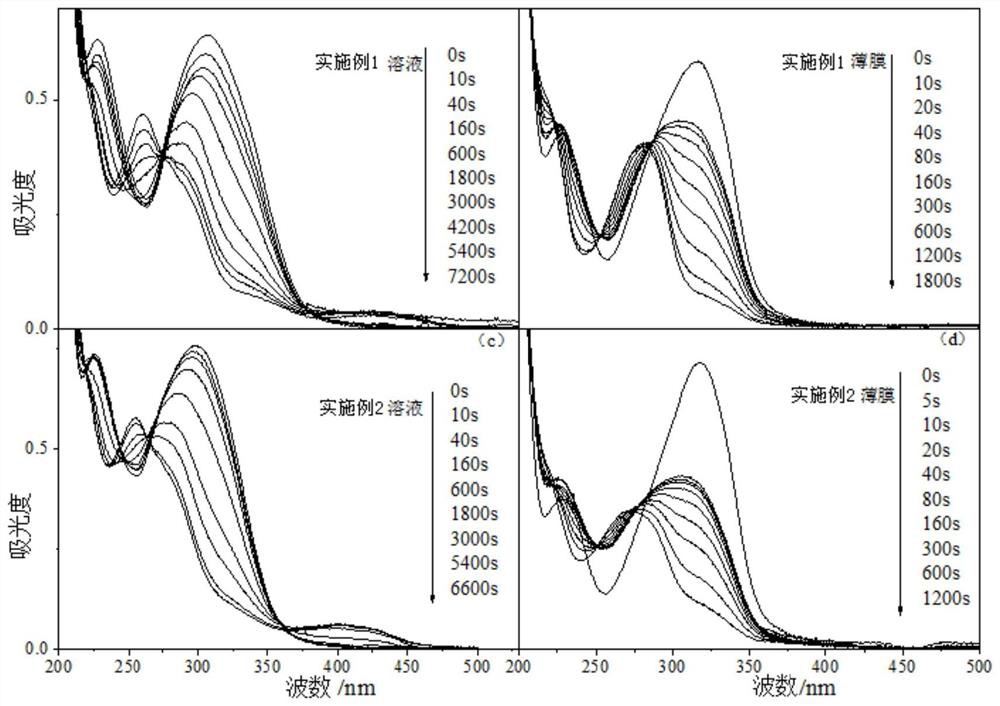

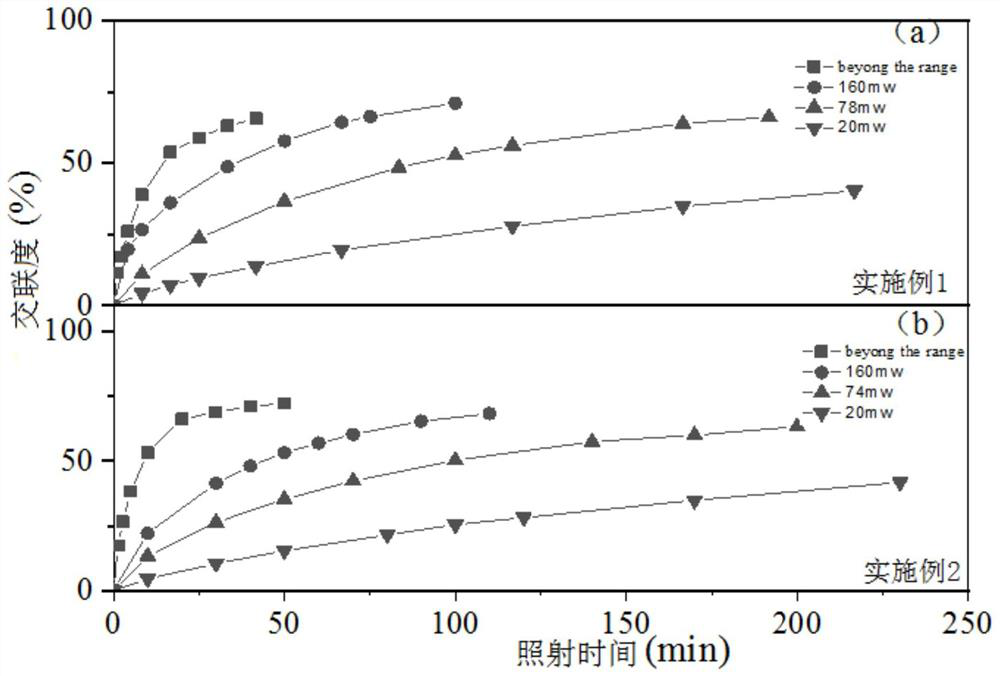

Embodiment 1

[0107] Under nitrogen protection, add 30g of isophorone diisocyanate (IPDI), 56g of polytetrahydrofuran ether glycol (PTMG-1000), 5.6g of dimethylolpropionic acid (DMPA) into the container, and heat up to 80°C , add 0.17g dibutyltin dilaurate (DBTDL), react for 3.5h, obtain isocyanate-terminated polyurethane;

[0108] Add 25g of 4-beta-hydroxyethyloxychalcone (HEOC) at a temperature of 80°C and react for 5h to obtain a chalcone-terminated aqueous polyurethane;

[0109] Cool down to 40°C, add 5g TEA, react for 20min-30min; then cool down to 25°C-30°C, add deionized water to control the solid content to 40wt.%, and stir at high speed for 1h at a stirring speed of 800r / min to obtain Char Ketone-terminated aqueous polyurethane emulsion PTMG-CWPU.

Embodiment 2

[0111] Prepare in a manner similar to Example 1, except that the soft segment is 56 g of polyethylene glycol (PEG-1000), and the other steps are the same to obtain a chalcone-terminated aqueous polyurethane emulsion PEG-CWPU.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com