Liquid-crystal-display-element sealant, vertical conductive material, and liquid-crystal display element

A technology of liquid crystal display components and sealants, applied in the direction of electrical components, adhesives, adhesive types, etc., can solve problems such as liquid crystal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

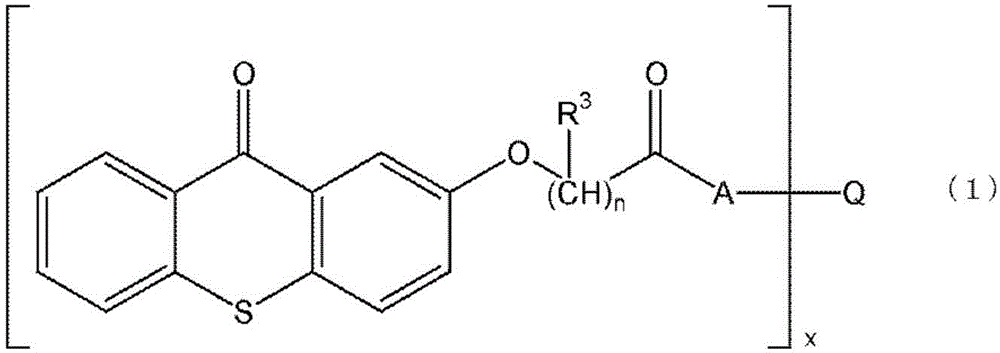

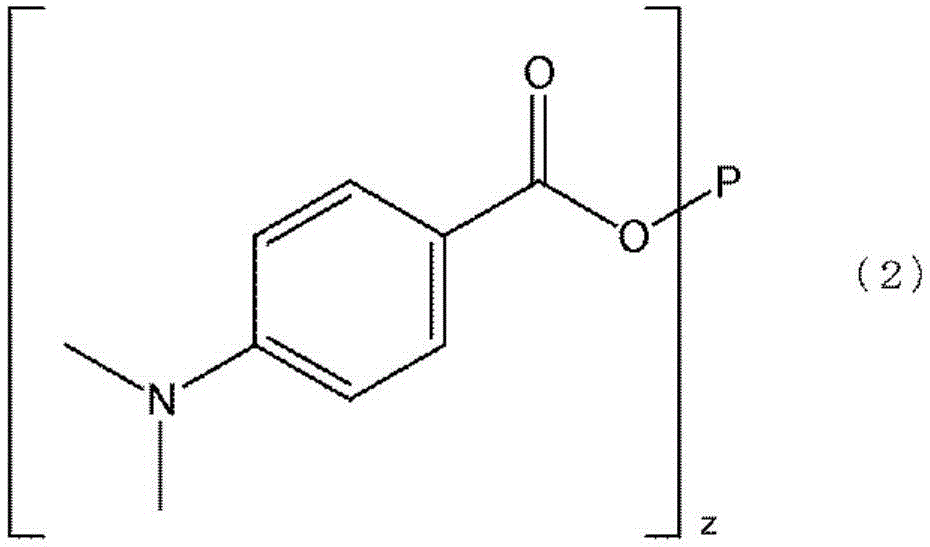

Method used

Image

Examples

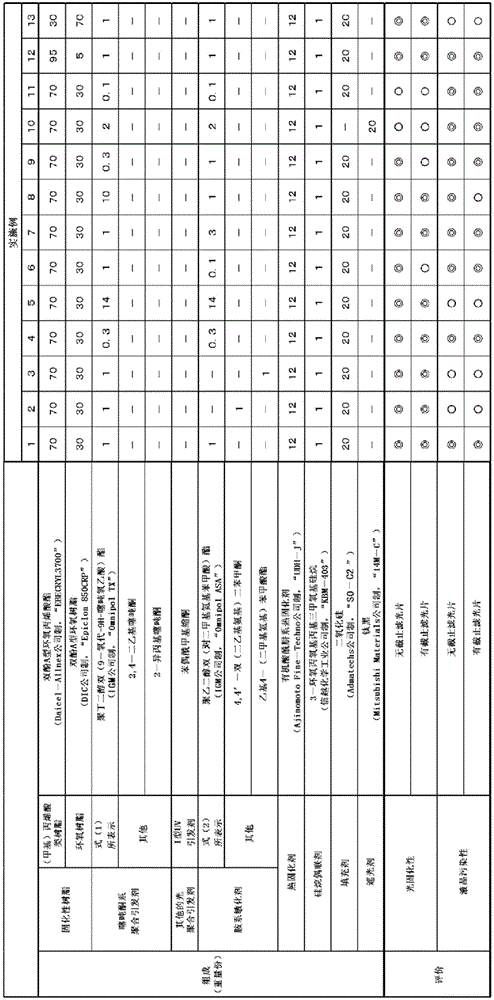

Embodiment 1~13、 comparative example 1~5

[0121] According to the compounding ratios described in Tables 1 and 2, each material was mixed using a planetary mixer ("わとり) Kontaro" manufactured by Thinky Co., Ltd.), and further mixed using a three-roll machine, thereby preparing Examples 1 to 2. 13. The sealing compound for each liquid crystal display element of Comparative Examples 1-5.

[0122]

[0123] The following evaluation was performed about each sealing compound for liquid crystal display elements obtained in the Example and the comparative example. The results are shown in Tables 1 and 2.

[0124] (photocurable)

[0125] A sealant obtained by dispersing 1 part by weight of spacer particles ("Micropearl SI-H050" manufactured by Sekisui Chemical Co., Ltd.) to 100 parts by weight of each sealant for liquid crystal display elements obtained in Examples and Comparative Examples was applied. On the glass substrate, a glass substrate of the same size is overlaid on the substrate, and then irradiated with a metal h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com