Sulfide solid electrolyte and preparation method and application thereof

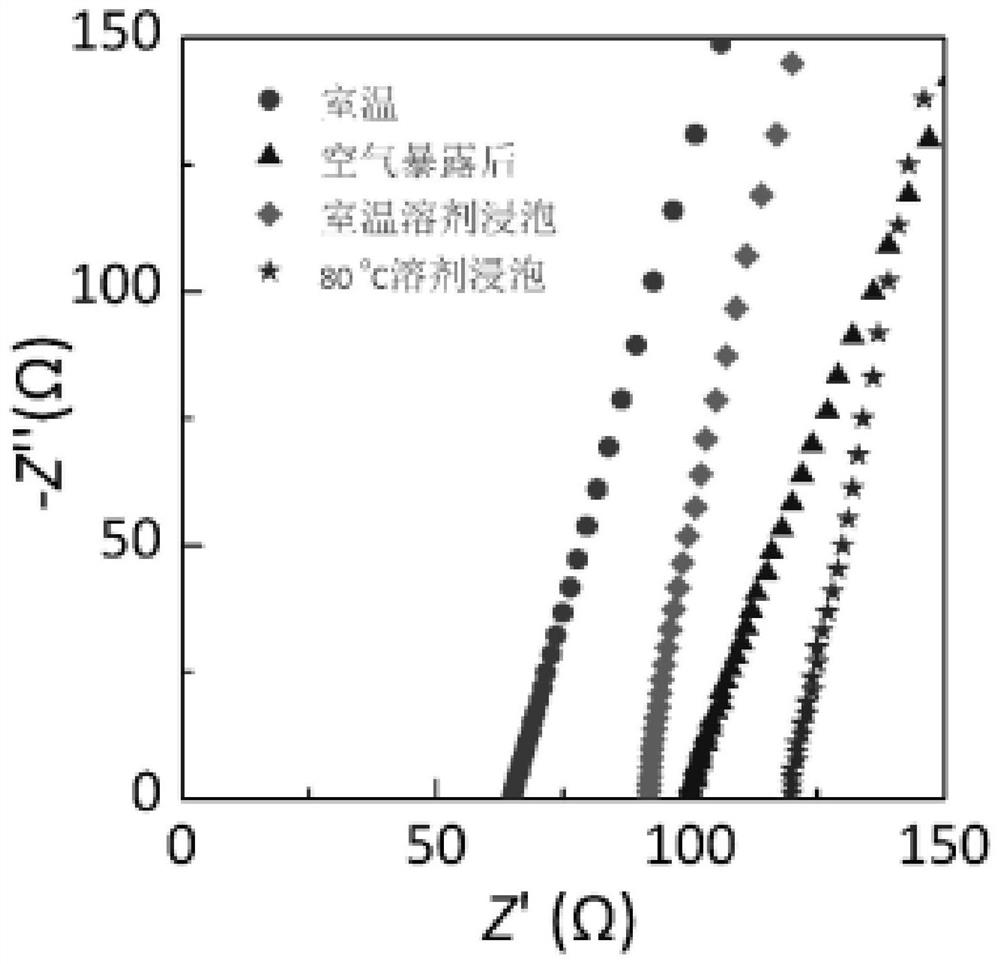

A solid electrolyte and sulfide technology, applied in the field of lithium-ion batteries, can solve the problems of low conductivity and poor stability, and achieve excellent lithium-ion conductivity and excellent air stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a sulfide solid state electrolyte, which is prepared by the following method:

[0037] Will Li 2 S, SiS 2 , Sb 2 S 5 , LiI, LiBr were added to the roller mill at a molar ratio of 28:6:4:7:3, and zirconia balls were added at the same time. The mass ratio of balls and raw materials was 10:1. The precursor powder was obtained by mixing at 300rpm for 24 hours. After the mixing was completed, the product was sintered at 550 °C for 12 hours under an argon atmosphere to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 5 I 0.7 Br 0.3 , the sheet density of the sulfide solid electrolyte is 95%.

[0038] The X-ray diffraction spectrum of the sulfide solid electrolyte is as follows figure 1 As shown, in the X-ray diffraction pattern, the characteristic peak 2Theta values of the sulfide solid electrolyte are 24.55°, 17.32°, 30.17°, 28.86°, 43.18°, 50.26°, 39.28° and 45.93° in sequence. Intensity I of the (111) plane of the LiI crystal phase I (...

Embodiment 2

[0040] This embodiment provides a sulfide solid state electrolyte, which is prepared by the following method:

[0041] Will Li 2 S, SiS 2 , Sb 2 S 5, LiI, LiBr were added to the high-energy ball mill at a molar ratio of 28:6:4:9:1, and zirconia balls were added at the same time. The mass ratio of balls to raw materials was 20:1, and the precursor powder was obtained by mixing at 550rpm for 12 hours. The product was sintered under vacuum at 450 °C for 6 hours to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 5 I 0.9 Br 0.1 , the sheet density of the sulfide solid electrolyte is 96%.

Embodiment 3

[0043] This embodiment provides a sulfide solid state electrolyte, and the sulfide solid state electrolyte is prepared by the following method:

[0044] Will Li 2 S, SiS 2 , Sb 2 S 5 , LiI, and LiBr were added into a mortar at a molar ratio of 28:6:4:3:7, and the precursor powder was obtained by hand-milling and mixing for 4 hours. The product was sintered at 500 °C for 12 hours in a nitrogen atmosphere to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 5 I 0.3 Br 0.7 , the sheet density of the sulfide solid electrolyte is 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com