Polymer composite material as well as preparation method and application thereof

A composite material and polymer technology, applied in the field of polymer composite materials to achieve the effect of excellent friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

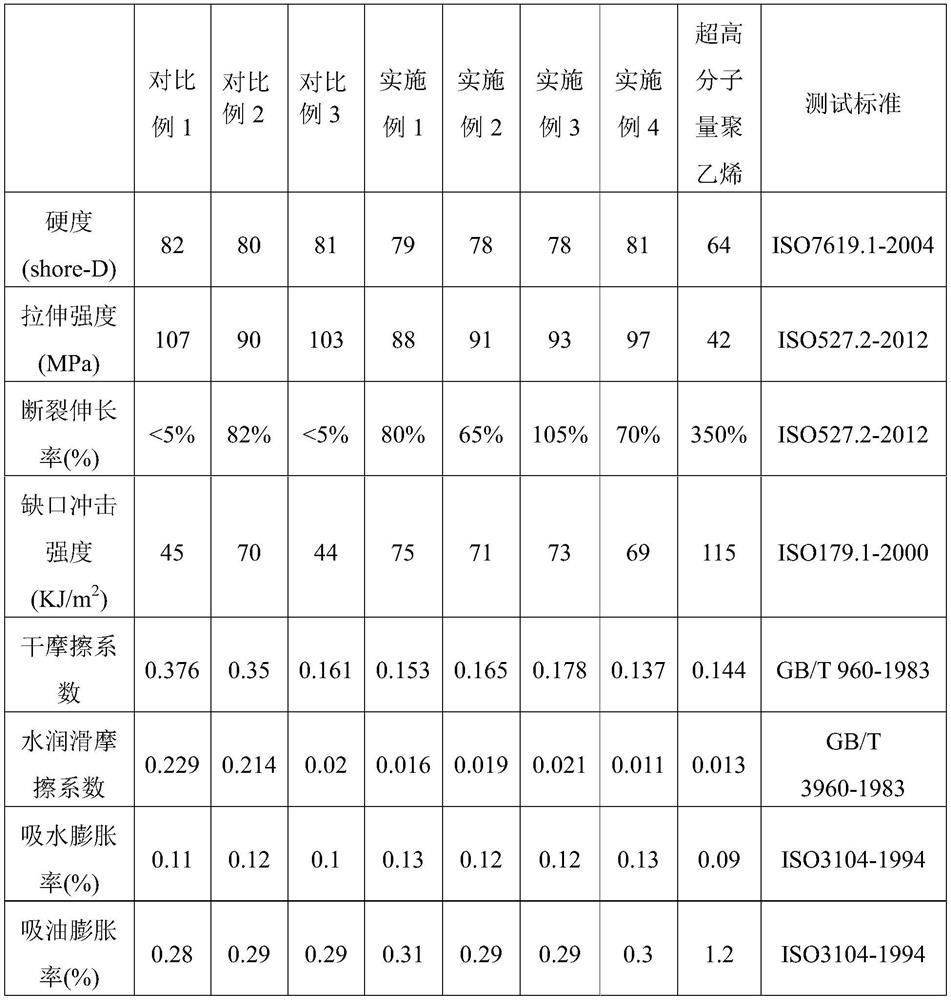

Examples

Embodiment 1

[0105] Step 1. Preparation of functional PU emulsion

[0106] 100g of polycaprolactone diol with a molecular weight of 2000 was vacuum dehydrated, and after cooling, it was added to a reaction device containing 200g of toluene and 17.5g of toluene diisocyanate. g of 1,4-butenediol, after continuing to react for 1 h, cooling to room temperature to obtain functional PU emulsion;

[0107] Step 2. Prepare PAEK solution

[0108] Dissolve 100 g of polyaryl ether ketone in 100 g of N,N-dimethylacetamide, fully stir to dissolve, and configure into a uniform solution with a solid content of 50%;

[0109] Step 3. Preparation of radiation-modified PTFE particles

[0110] The trade name of Shenyang Wuliang Technology Co., Ltd. is PTFE micropowder for coating (particle size is 1-10 microns), directly modified with electron beam irradiation dose of 1200KGy, the treatment time is 120 days, and the daily dose is 10KGy ;

[0111] Step 4. Preparation of PU-PAEK-PTFE three-phase composite mi...

Embodiment 2

[0116] Step 1. Preparation of functional PU emulsion

[0117] 100g of polytetrahydrofuran ether glycol with a molecular weight of 1000 was dehydrated in vacuum, and after cooling, it was added to a reaction device containing 250g of acetone and 50g of diphenylmethane diisocyanate. 22.8g of 1,5-hexadiene-3,4-diol, after continuing to react for 1h, cooled to room temperature to obtain functional PU emulsion;

[0118] Step 2. Prepare PAEK solution

[0119] Dissolve 100 g of polyaryl ether ketone in 60 g of sulfolane, fully stir and dissolve, and configure into a uniform solution with a solid content of 62.5%;

[0120] Step 3. Preparation of radiation-modified PTFE particles

[0121] The trade name of Shenyang Wuliang Technology Co., Ltd. is PTFE micropowder for ink, and it is directly modified with an electron beam irradiation dose of 1200KGy, the treatment time is 120 days, and the daily dose is 10KGy;

[0122] Step 4. Preparation of PU-PAEK-PTFE three-phase composite micropo...

Embodiment 3

[0127] Step 1. Preparation of functional PU emulsion

[0128] 100g of polyethylene adipate glycol with a molecular weight of 3000 was vacuum dehydrated, and after cooling, it was added to a reaction device containing 80g of dimethyl sulfoxide and 10.68g of p-phenylenediisocyanate, and under a nitrogen atmosphere, After reacting at 70°C for 1.5 hours, 7.6 g of 2,4-hexadiene-1,6-diol was added, and after continuing the reaction for 1.5 hours, the temperature was cooled to room temperature to obtain a functional PU emulsion;

[0129] Step 2. Prepare PAEK solution

[0130] Dissolve 100 g of polyaryl ether ketone in 150 g of dimethyl sulfoxide, fully stir to dissolve, and configure into a uniform solution with a solid content of 40%;

[0131] Step 3. Preparation of radiation-modified PTFE particles

[0132] The trade name of Shenyang Wuliang Technology Co., Ltd. is PTFE micropowder for lubricating grease, directly modified with electron beam irradiation dose of 1000KGy, the treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com