Automobile brake pad graphene hybrid/PEEK plastic and reparation method

A polyetheretherketone, automobile brake technology, applied in the field of automobile brake pad graphene hybrid/polyetheretherketone plastic and preparation, can solve the problems of easy corrosion, high price and high cost of semi-metal brake pads, and achieve friction Excellent performance, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

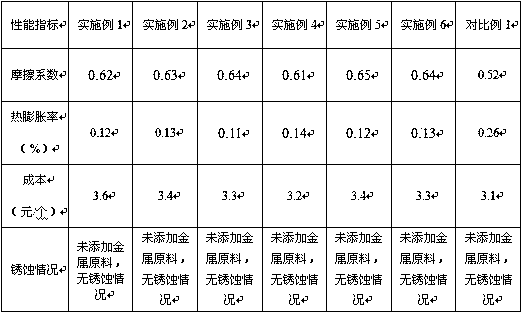

Examples

Embodiment 1

[0031] The preparation process is:

[0032] (1) Disperse graphene oxide in water, add nano-montmorillonite, polyamide-amine dendritic molecule (PAMAM), ultrasonically disperse, then add ascorbic acid as a reducing agent, stir evenly with magnetic force, and obtain dendritic PAMAM / graphene / montmorillonite mixed solution; wherein, 17 parts by weight of graphene oxide, 55 parts by weight of water, 3 parts by weight of nano-montmorillonite, 23 parts by weight of polyamide-amine dendrimer, 2 parts by weight of ascorbic acid; the time of ultrasonic dispersion is 2h, the time of magnetic stirring is 8h;

[0033] (2) Add calcium hydroxide suspension to the mixed solution prepared in step (1), drop into sulfuric acid solution, heat up to react, then add crystallization directing agent, filter and dry to obtain calcium sulfate whiskers and A hybrid of dendritic PAMAM / graphene / montmorillonite; wherein, 57 parts by weight of mixed solution, 23 parts by weight of calcium hydroxide suspen...

Embodiment 2

[0041] The preparation process is:

[0042] (1) Disperse graphene oxide in water, add nano-montmorillonite, polyamide-amine dendritic molecule (PAMAM), ultrasonically disperse, then add ascorbic acid as a reducing agent, stir evenly with magnetic force, and obtain dendritic PAMAM / graphene / montmorillonite mixed solution; wherein, 15 parts by weight of graphene oxide, 62 parts by weight of water, 2 parts by weight of nano-montmorillonite, 20 parts by weight of polyamide-amine dendrimer, 1 part by weight of ascorbic acid; the time of ultrasonic dispersion is 1h, the time of magnetic stirring is 9h;

[0043] (2) Add calcium hydroxide suspension to the mixed solution prepared in step (1), drop into sulfuric acid solution, heat up to react, then add crystallization directing agent, filter and dry to obtain calcium sulfate whiskers and A hybrid of dendritic PAMAM / graphene / montmorillonite; wherein, 60 parts by weight of mixed solution, 22 parts by weight of calcium hydroxide suspens...

Embodiment 3

[0051] The preparation process is:

[0052] (1) Disperse graphene oxide in water, add nano-montmorillonite, polyamide-amine dendritic molecule (PAMAM), ultrasonically disperse, then add ascorbic acid as a reducing agent, stir evenly with magnetic force, and obtain dendritic PAMAM / graphene / montmorillonite mixed solution; wherein, 20 parts by weight of graphene oxide, 48 parts by weight of water, 4 parts by weight of nano-montmorillonite, 25 parts by weight of polyamide-amine dendrimer, 3 parts by weight of ascorbic acid; the time of ultrasonic dispersion is 3h, the time of magnetic stirring is 9h;

[0053] (2) Add calcium hydroxide suspension to the mixed solution prepared in step (1), drop into sulfuric acid solution, heat up to react, then add crystallization directing agent, filter and dry to obtain calcium sulfate whiskers and A hybrid of dendritic PAMAM / graphene / montmorillonite; wherein, 52 parts by weight of mixed solution, 25 parts by weight of calcium hydroxide suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com