Silicon disulfide and preparation method thereof

A silicon disulfide and silicon powder technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of low powder phase purity and chemical purity, poor safety, complex equipment and procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The present embodiment provides a preparation method of silicon disulfide, specifically:

[0075] S1) Weigh a certain amount of solar (or above) grade (>99.9999wt.%) silicon block, crush it with a tungsten steel or steel device, and pass it through a 20-mesh (<0.85mm) sieve to obtain coarse Si powder;

[0076] S2) place the coarse Si powder in a planetary ball mill to carry out wet ball milling, use a stainless steel tank as the ball milling tank, use tungsten carbide-cobalt (WC-Co) balls as the ball milling medium, use anhydrous ethanol as the ball milling liquid, and the ball milling speed is Revolve at 150rpm, rotate at 300rpm, and ball mill for 2h to obtain Si slurry;

[0077] S3) ultrasonically clean the Si slurry prepared in S2) with 10 wt.% hydrochloric acid (HCl) three times, each 10 min; ultrasonically clean it with 6 wt.% hydrofluoric acid (HF) three times, each 10 min; use ultrapure water (resistance rate 18MΩ·cm, impurities - And it is neutral; vacuum-dryin...

Embodiment 2

[0082] The present embodiment provides a preparation method of silicon disulfide, specifically:

[0083] In the second embodiment, except that the holding temperature in the fifth step is different from that of the first embodiment, the rest are the same as those of the first embodiment.

[0084] The 5th step of embodiment two is as follows:

[0085] Mix and grind high-purity silicon powder and high-purity sulfur powder at the ratio of Si:S=1:3.3 (mol%), protect and seal it in a vacuum (≤10Pa) quartz tube with argon gas, set an inclination angle of 20°, and set the inclination angle of 20°. The tube was placed in a high-temperature furnace, raised to 800°C at 5°C / min, kept for 3 hours, mainly for solid / gas two-phase chemical reaction synthesis, then cooled to room temperature at 5°C / min, passed through a 200-mesh (<74μm) sieve, A rod-shaped silicon disulfide powder was obtained.

[0086] ICP tested, SiS 2 The impurity content is 3174ppm (mg / L), and the K / Na content is extre...

Embodiment 3

[0088] The present embodiment provides a preparation method of silicon disulfide, specifically:

[0089] In Example 3, except for the addition of the last step (surface treatment and modification of benzene to silicon disulfide), the rest are the same as in Example 1.

[0090] The last step of embodiment three is as follows:

[0091] The synthesized product was surface-treated and modified with benzene (≥99.5 wt.%), filtered, vacuum-dried at 80° C. for 5 h, and passed through a 200-mesh (2 The impurity content is 3227ppm (mg / L), and the impurity content without K / Na is 2141ppm (mg / L).

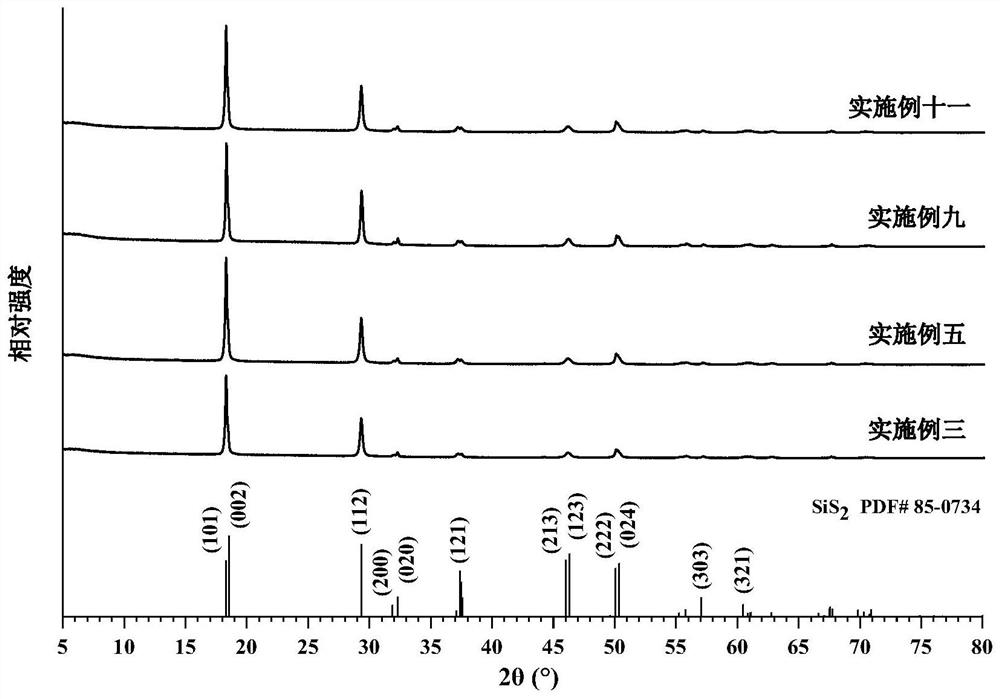

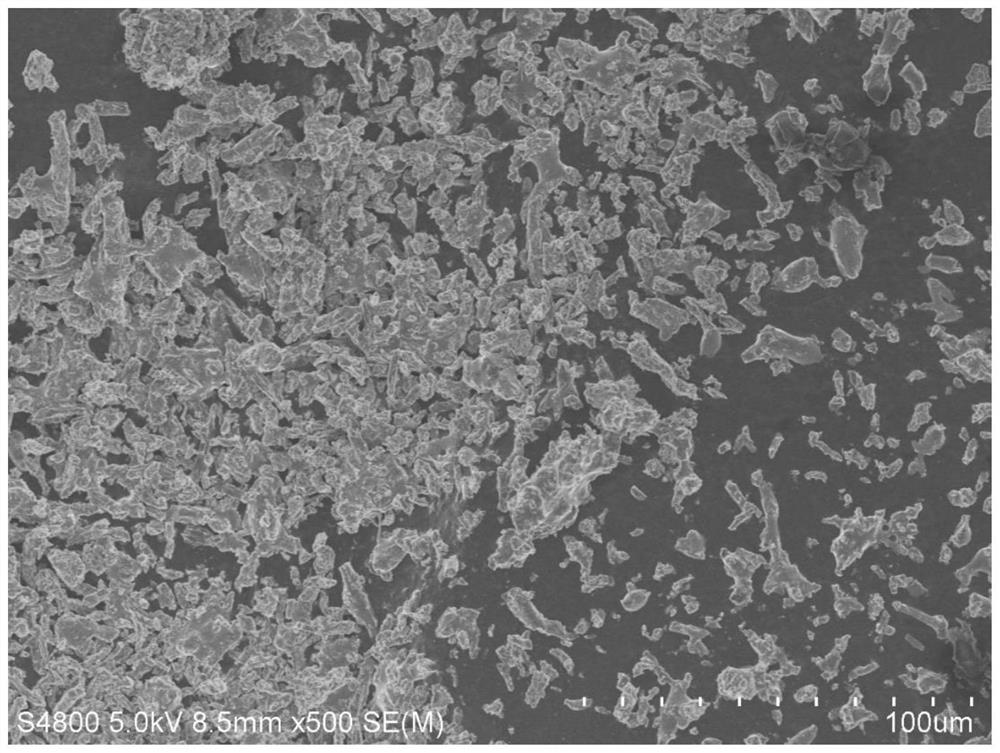

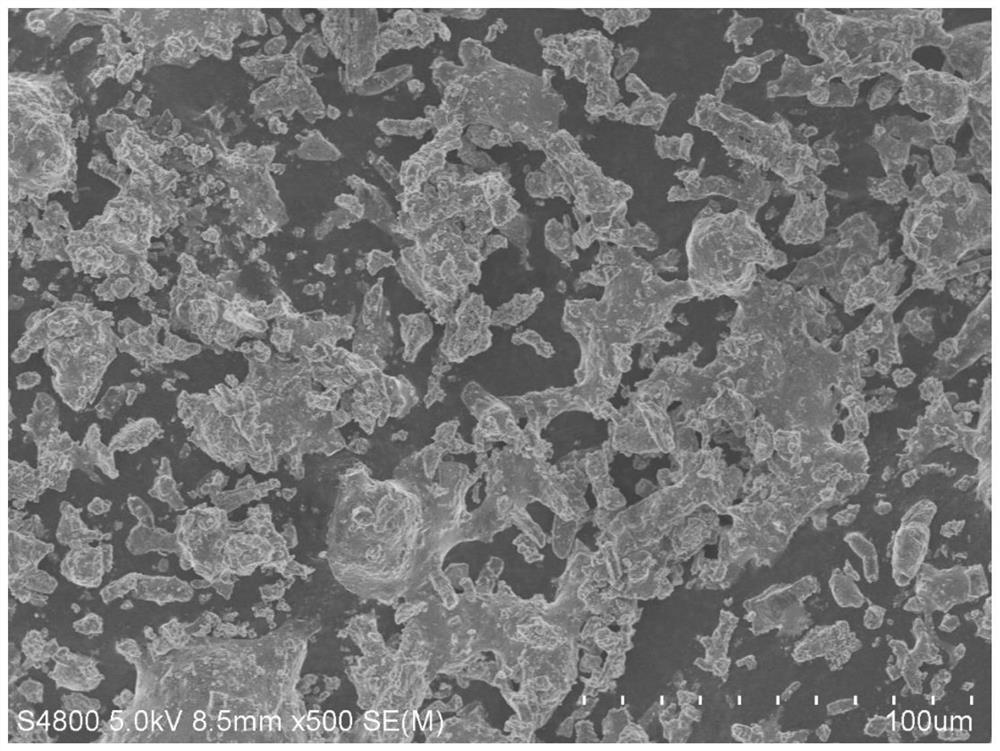

[0092] XRD test ( figure 1 ) showed that the polycrystalline particles had high phase purity and were preferentially aligned perpendicular to the (101) / (002) / (112) crystal planes; SEM tests ( figure 2 ) show that the rod-shaped particles have an aspect ratio of 2-7 and a size distribution of L9-35 × D3-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com