Arranging method of super-hydrophobic and hydrophilic double-faced heterologous cotton fabric

A technology for double-sided heterosexual, cotton fabrics, applied in fiber processing, textiles and papermaking, etc., can solve the problems of high hygroscopicity, unevenness, and difficulty in single-sided hydrophobic finishing, etc., to achieve convenient operation, good hydrophobic effect, good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

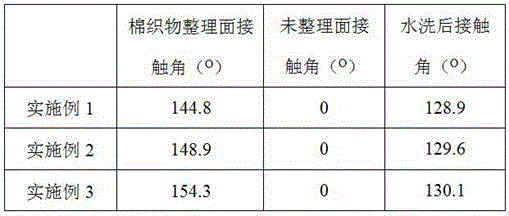

Embodiment 1

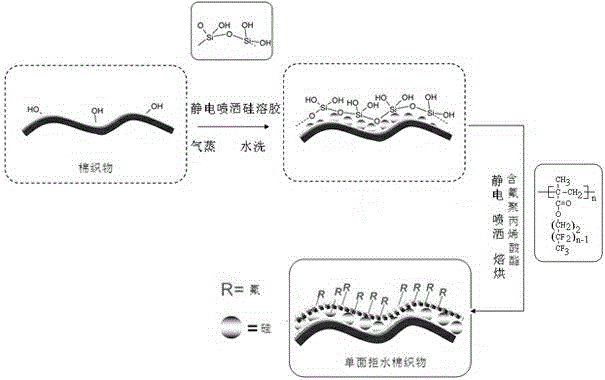

[0031] The finishing method of the superhydrophobic and hydrophilic double-sided heterosexual cotton fabric of the present embodiment, the steps are as follows:

[0032] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

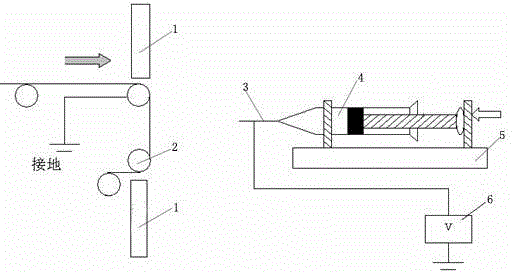

[0033] (2) Fix the fabric on the metal drum collection device, the rotation speed of drum 2 is 50 rpm, and the metal drum collection device is connected to the negative electrode of high voltage generator 6;

[0034] (3) Put 1% silica sol finishing agent with pH=4 in the syringe 4, place it on the syringe pump, and fix the positive electrode of the high-voltage generator 6 on the metal needle 3 of No. 9;

[0035] (4) Adjust the distance between the roller 2 and the metal No. 9 needle 3 at 10cm, the voltage at 15kv, and control the flow rate at 1ml / min. Spray the silica sol finishing agent evenly on the surface of the fabric in small droplets, and control the spray flow rate, frequency and time. Ensure that wetting only occurs on o...

Embodiment 2

[0039] The finishing method of the superhydrophobic and hydrophilic double-sided heterosexual cotton fabric of the present embodiment, the steps are as follows:

[0040] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

[0041] (2) Fix the fabric on the metal drum collection device, the drum speed is 200 rpm, and the metal drum collection device is connected to the negative pole of the high voltage generator;

[0042] (3) Put 2% silica sol finishing agent with pH=4 in the syringe, place it on the syringe pump, and fix the positive electrode of the high-voltage generator on the metal No. 9 needle;

[0043] (4) Adjust the distance between the roller and the needle at 20cm, the voltage at 25kv, control the flow rate at 5ml / min, spray the silica sol finishing agent on the surface of the fabric evenly in small droplets, control the spray flow rate, frequency and time, and ensure that only wetting occurs On one side of cotton fabric;

[0044] (5) Steam...

Embodiment 3

[0047] The finishing method of the superhydrophobic and hydrophilic double-sided heterosexual cotton fabric of the present embodiment, the steps are as follows:

[0048] (1) Pre-condition the cotton fabric to control the moisture regain at 8±0.5%;

[0049] (2) Fix the fabric on the metal drum collection device, the drum speed is 500 rpm, and the metal drum collection device is connected to the negative pole of the high voltage generator;

[0050] (3) Put 3% silica sol finishing agent with pH=4 in the syringe, place it on the syringe pump, and fix the positive electrode of the high-voltage generator on the metal No. 9 needle;

[0051] (4) Adjust the distance between the roller and the needle at 20cm, the voltage at 30kv, and control the flow rate at 10ml / min. Spray the silica sol finishing agent on the surface of the fabric evenly in small droplets, and control the spray flow rate, frequency and time to ensure that only wetting occurs. On one side of cotton fabric;

[0052] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com