Double-strategy modified layered oxide sodium-ion battery positive electrode material as well as preparation method and application thereof

A sodium-ion battery and positive electrode material technology, applied in active material electrodes, chemical electrode manufacturing, electrode manufacturing, etc., can solve problems such as unsatisfactory cycle stability, and achieve good industrial production potential, good application prospects, and high working voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

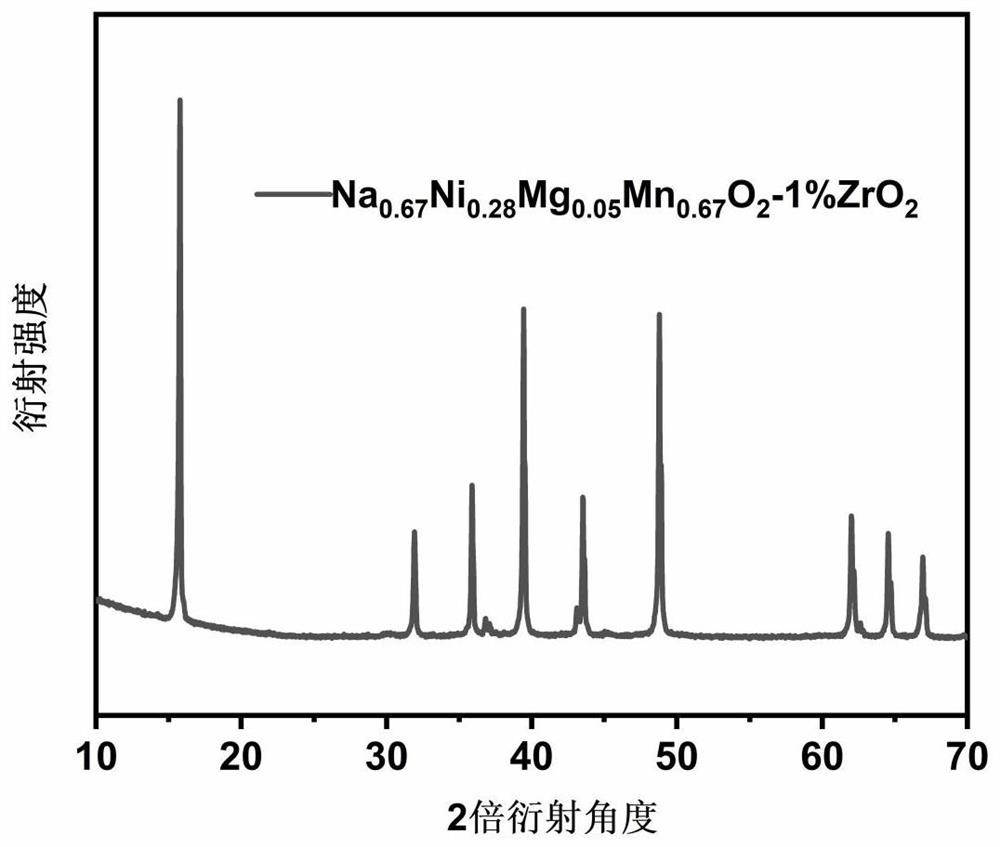

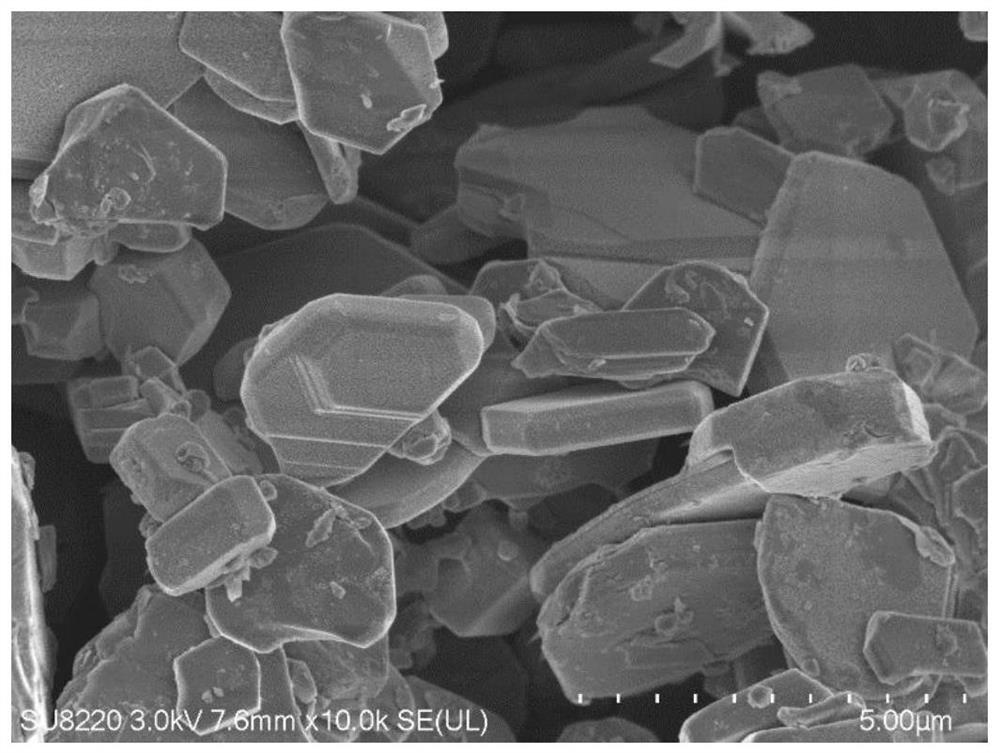

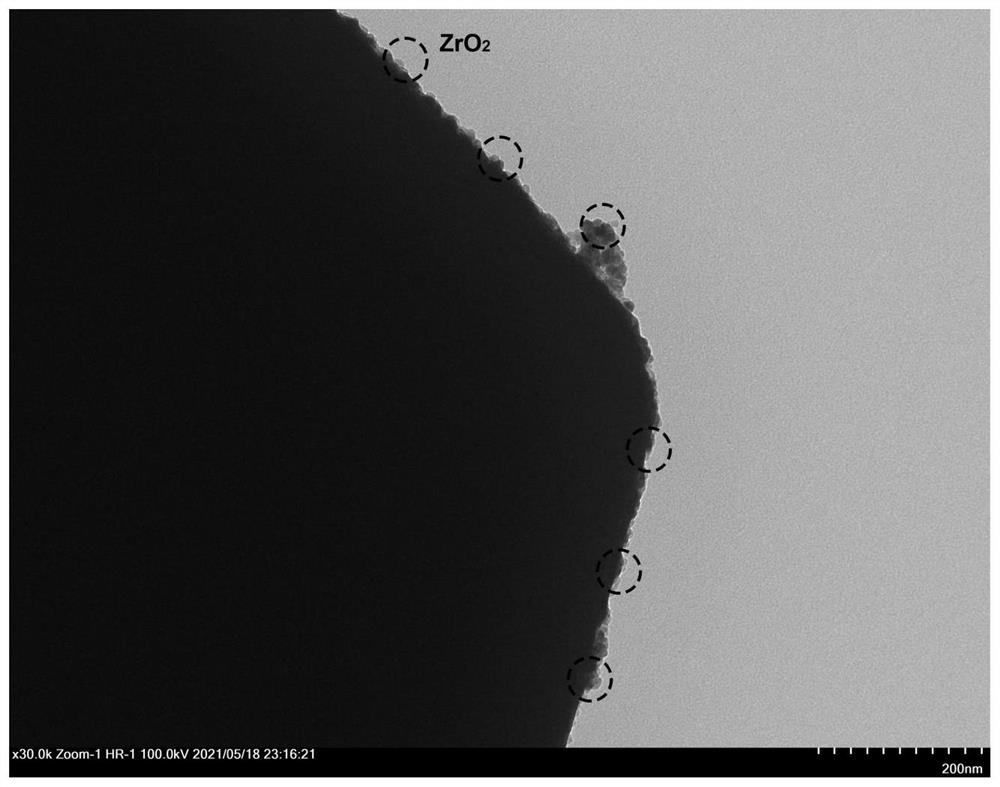

[0042] Step 1, sol-gel method combined with wet chemical method to prepare Na 0.67 Ni 0.28 Mg 0.05 mn 0.67 o 2 -1%ZrO 2 Cathode material

[0043] The target product of synthesis is Na 0.67 Ni 0.28 Mg 0.05 mn 0.67 o 2 -1%ZrO 2 The positive electrode material is composed of sodium acetate, nickel acetate, magnesium acetate and manganese acetate, the chelating agent is citric acid, and the solvent is deionized water.

[0044] Sodium acetate, nickel acetate, magnesium acetate and manganese acetate are dissolved in desiccant according to the molar ratio in the target product and citric acid (the total molar weight of sodium, nickel, magnesium and manganese metal ions and the molar ratio of citric acid are 1:1.6). In deionized water, place in an oil bath at 80°C with constant stirring and evaporate to dryness until a gel is formed. The gel was dried in an oven at 150 °C for 6 h, and then it was ground in a mortar to obtain the precursor powder. The precursor powder was ...

Embodiment 2

[0059] The preparation method is the same as that of Example 1, except that the raw materials are 0.67 Ni 0.28 Mg 0.05 mn 0.67 o 2 -0.5%ZrO 2 The stoichiometric ratio is added.

[0060] Figure 9 It is the XRD spectrum of the target product obtained in Example 2. It can be seen from the figure that the synthesized material has good crystallinity, and has a P2 phase structure and a P63 / mmc space group.

[0061] Figure 10 For the obtained target product of embodiment 2 at 0.1C (1C=173mAg -1 ) charge-discharge curve at the current density, it can be seen from the figure that this material has a higher specific capacity of 122.9mAh g when applied to sodium-ion batteries -1 .

Embodiment 3

[0063] The preparation method is the same as that of Example 1, except that the raw materials are 0.67 Ni 0.28 Mg 0.05 mn 0.67 o 2 -2%ZrO 2 The stoichiometric ratio is added.

[0064] Figure 11 It is the XRD spectrum of the target product obtained in Example 3. It can be seen from the figure that the synthesized material has good crystallinity, and has a P2 phase structure and a P63 / mmc space group.

[0065] Figure 12 For the obtained target product of embodiment 3 at 0.1C (1C=173mAg -1 ) charge-discharge curve at the current density, it can be seen from the figure that this material has a higher specific capacity of 114.6mAh g when applied to sodium-ion batteries -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com