A kind of preparation method of orange-red light emitting tunable BCNO phosphor

A phosphor, orange-red light technology, used in chemical instruments and methods, luminescent materials, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

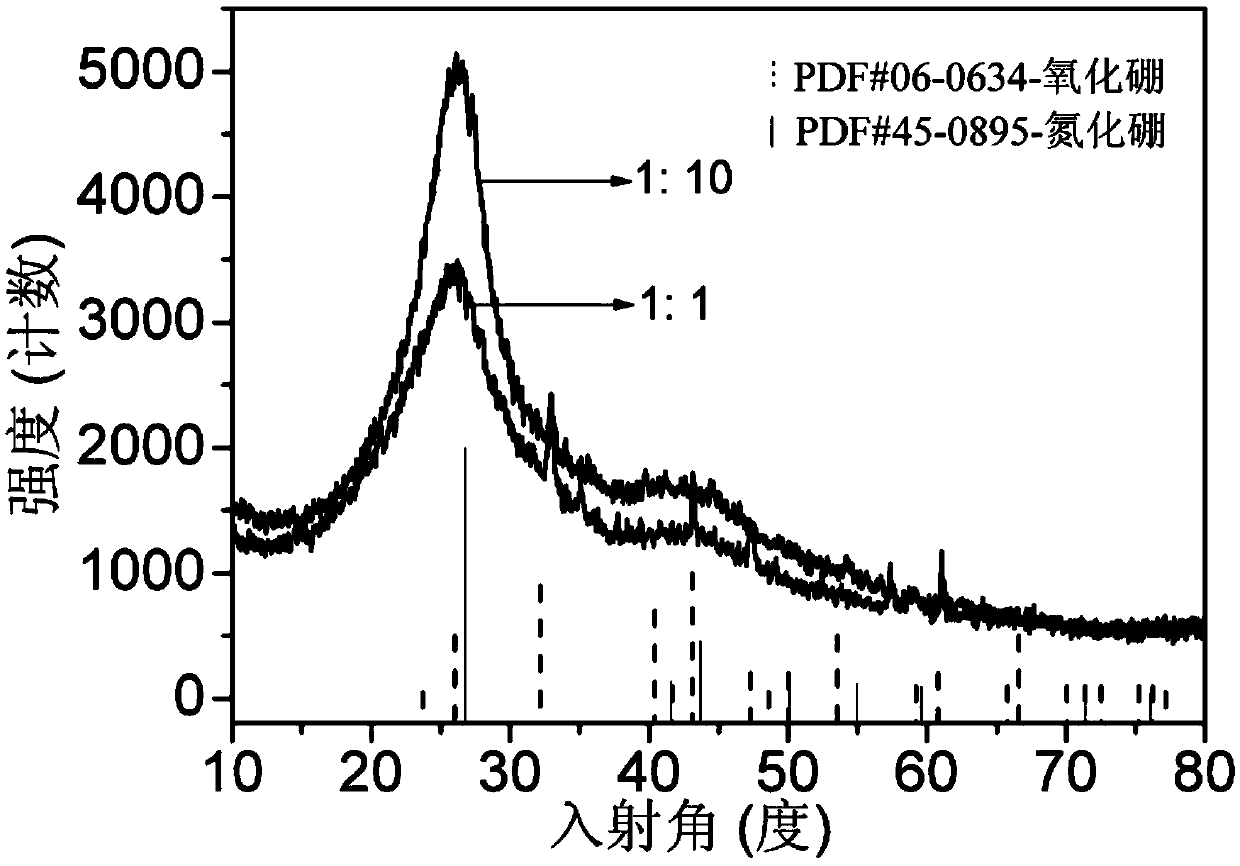

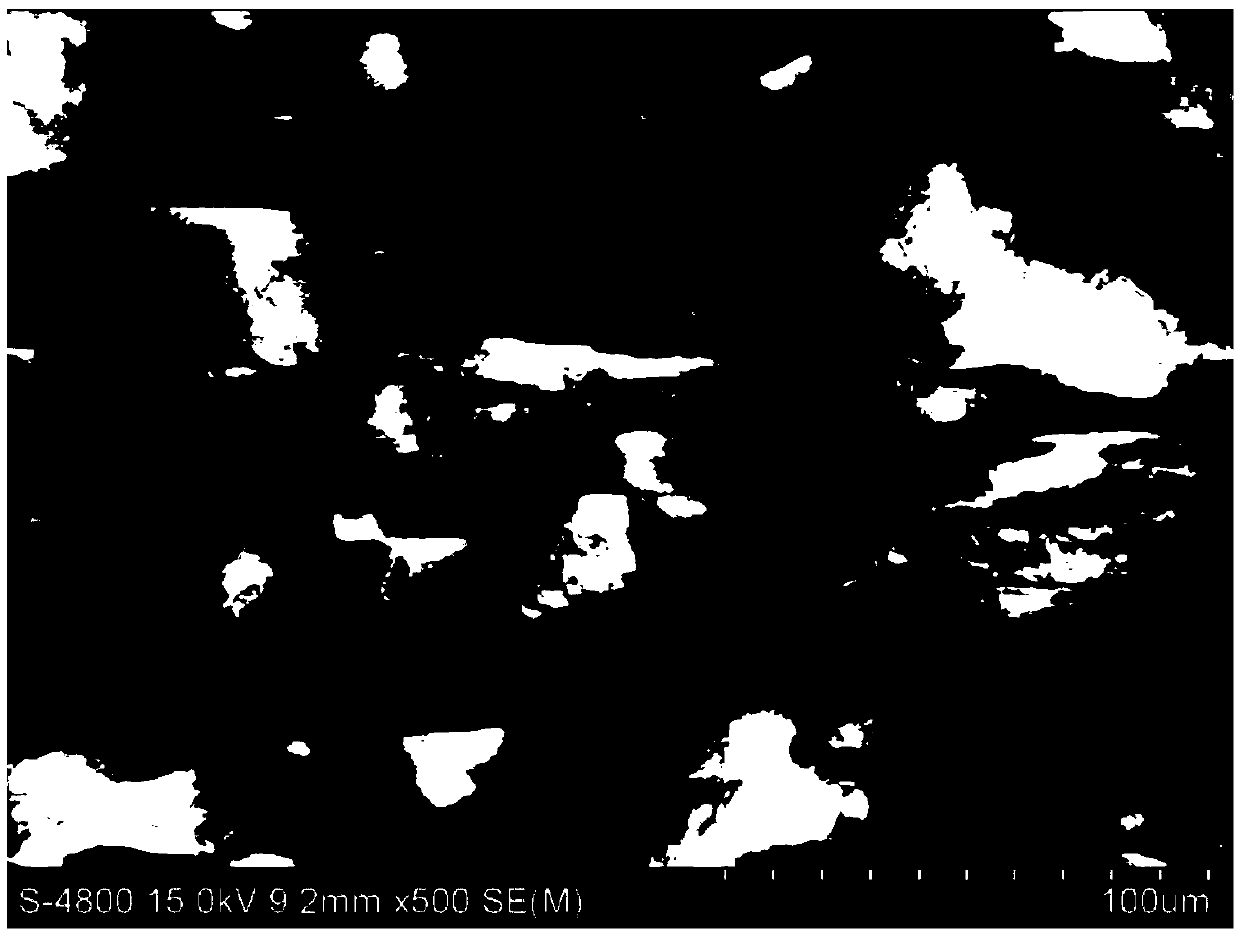

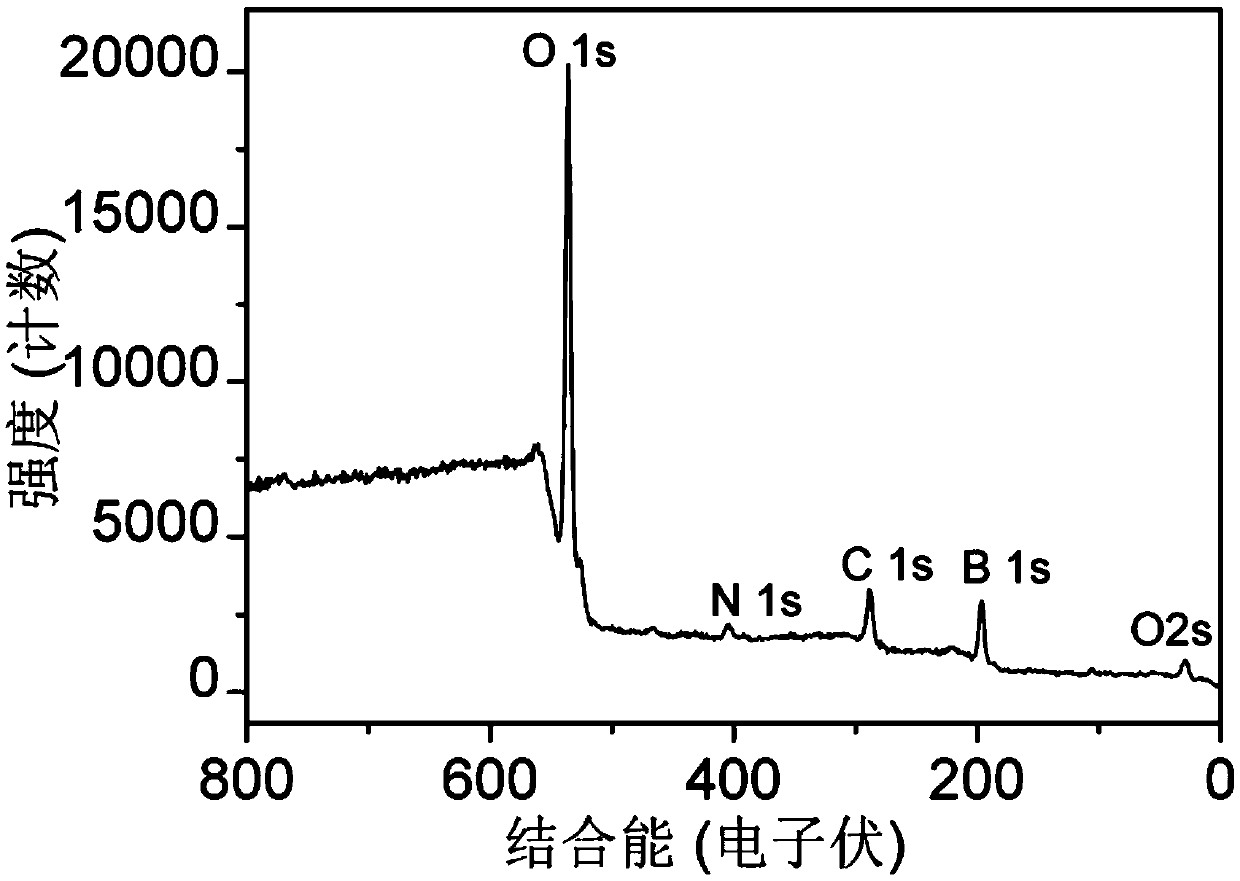

[0020] Example 1: Preparation of orange-emitting BCNO phosphors at different sintering temperatures.

[0021] Step 1: Weigh boric acid (0.02mol) and α-alanine (0.02mol) according to the chemical molar ratio of 1:1, put the weighed boric acid and α-alanine into an oven for heating pretreatment, heat The temperature is 120 degrees, and the heating time is 4 hours. After the heating is completed, it is naturally cooled to room temperature;

[0022] Step 2: Put the pretreated boric acid and α-alanine into a beaker, then add 30 milliliters of deionized water (the amount of deionized water is enough to completely dissolve the boric acid and α-alanine, here for convenience of experiment , choose 30 milliliters, and carry out heating and stirring (electromagnetic stirring, rotating speed is 80 rpm.), heating temperature is 50 ℃, continuous stirring time is 4 hours; stem, to obtain the precursor of BCNO;

[0023] Step 3: Put the BCNO precursor prepared in the previous step into an al...

Embodiment 2

[0025] Other steps are the same as in Example 1, except that the sintering temperature in step 3 is changed from 600 degrees to 625 degrees.

Embodiment 3

[0027] Other steps are the same as in Example 1, except that the sintering temperature in step 3 is changed from 600 degrees to 650 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com