A kind of high entropy zirconate ceramics and preparation method thereof

A zirconate and ceramic technology, applied in the field of ceramic materials and their preparation, can solve the problems of low density of high-entropy ceramic sintered samples, no high-entropy zirconate ceramics, difficult application of high-entropy ceramics, etc., and achieve great application potential , Excellent material properties, the effect of filling the research gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

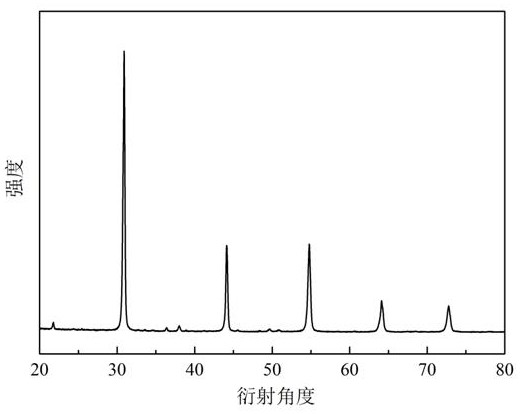

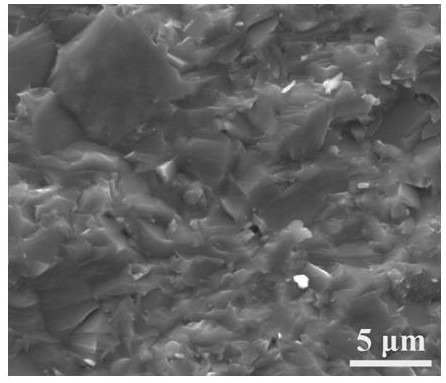

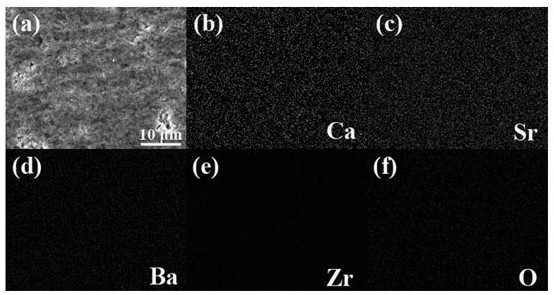

[0030] A high-entropy zirconate ceramic, the chemical formula of which is (CaSrBa)ZrO 3 , high-entropy zirconate ceramic (CaSrBa)ZrO 3 Has a single phase structure.

[0031] Preparation of High-Entropy Zirconate Ceramics (CaSrBa)ZrO 3 method, including the following steps:

[0032] (1) Three kinds of zirconate CaZrO 3 , SrZrO 3 and BaZrO 3 Powder, according to the molar ratio of CaZrO 3 : SrZrO 3 : BaZrO 3 =1:1:1 to form mixed powder;

[0033] (2) Put the mixed powder described in step (1) into a polytetrafluoroethylene tank, add anhydrous ethanol and zirconia grinding balls, and the mass ratio of the balls to the material is 1:1; use a planetary ball mill to wet mixing , the rotating speed is 300 r / min, and the ball milling time is 4 h to obtain a uniformly mixed suspension;

[0034] (3) Transfer the suspension in step (2) into an eggplant-shaped bottle and fully dry the evenly mixed suspension with a rotary evaporator at a drying temperature of 40-60 o C, the dryi...

Embodiment 2

[0037] A high-entropy zirconate ceramic, the chemical formula of which is (CaSrBa)ZrO 3 , high-entropy zirconate ceramic (CaSrBa)ZrO 3 Has a single phase structure.

[0038] Preparation of High-Entropy Zirconate Ceramics (CaSrBa)ZrO 3 method, including the following steps:

[0039] (1) Three kinds of zirconate CaZrO 3 , SrZrO 3 and BaZrO 3 Powder, according to the molar ratio of CaZrO 3 : SrZrO 3 : BaZrO 3 =1:1:1 to form mixed powder;

[0040] (2) Put the mixed powder described in step (1) into a polytetrafluoroethylene tank, add anhydrous ethanol and zirconia grinding balls, and the mass ratio of the balls to the material is 1:1; use a planetary ball mill to wet mixing , the rotating speed is 300 r / min, and the ball milling time is 4 h to obtain a uniformly mixed suspension;

[0041] (3) Transfer the suspension in step (2) into an eggplant-shaped bottle and fully dry the evenly mixed suspension with a rotary evaporator at a drying temperature of 40-60 o C, the dryi...

Embodiment 3

[0044] A high-entropy zirconate ceramic, the chemical formula of which is (CaSrBa)ZrO 3 , high-entropy zirconate ceramic (CaSrBa)ZrO 3 Has a single phase structure.

[0045] Preparation of High-Entropy Zirconate Ceramics (CaSrBa)ZrO 3 method, including the following steps:

[0046] (1) Three kinds of zirconate CaZrO 3 , SrZrO 3 and BaZrO 3 Powder, according to the molar ratio of CaZrO 3 : SrZrO 3 : BaZrO 3 =1:1:1 to form mixed powder;

[0047] (2) Put the mixed powder described in step (1) into a polytetrafluoroethylene tank, add anhydrous ethanol and zirconia grinding balls, and the mass ratio of the balls to the material is 1:1; use a planetary ball mill to wet mixing , the rotating speed is 300 r / min, and the ball milling time is 4 h to obtain a uniformly mixed suspension;

[0048] (3) Transfer the suspension in step (2) into an eggplant-shaped bottle and fully dry the evenly mixed suspension with a rotary evaporator at a drying temperature of 50 °C. o C, the dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com