A rapid repair refractory material and its preparation and use method

A refractory material and fast technology, applied in the field of refractory materials, can solve the problems of short service life of refractory materials, and achieve the effect of good thermal shock stability, high strength and rich material system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

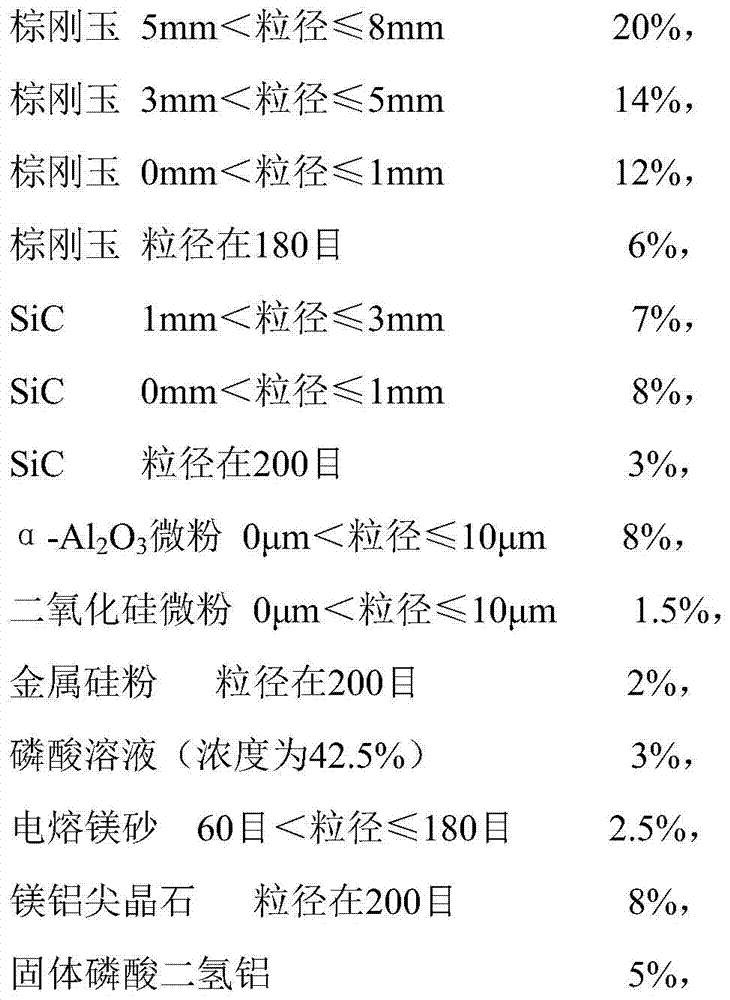

[0024] A kind of rapid repair refractory material, by mass percentage, the composition is as follows:

[0025]

[0026] During construction, the above-mentioned formula materials are formulated into products according to the production process, and each bag of material in the product packaging is poured into a forced mixer and mixed for two minutes. After mixing evenly, add water. The amount of water added is 2.8% of the total weight of the formula materials, and continue to stir From 3 minutes to 5 minutes, sample 1 was prepared by ramming method; according to the same method, the amount of water added was 5.8% of the total weight of the formula material, sample 2 was prepared by vibration casting method, and its performance index was tested.

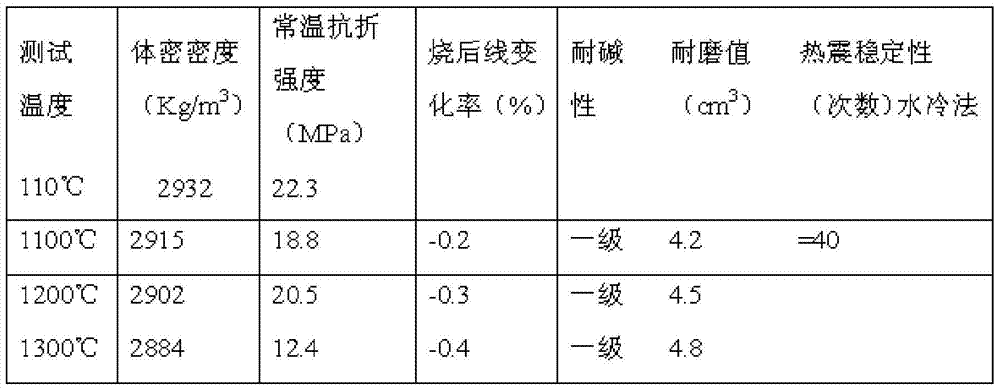

[0027] Table 1 Sample 1 Performance Index

[0028]

[0029] Table 2 Performance index of sample 2

[0030]

Embodiment 2

[0032] A kind of rapid repair refractory material, by mass percentage, the composition is as follows:

[0033]

[0034] During construction, above-mentioned example Ⅱ formula material is formulated into product according to production process, and each bag material in the product packaging is poured into the compulsory mixer and mixed and stirred for 2 minutes, after mixing evenly, add water, and the amount of water added is 3% of the formula material gross weight, Stirring was continued for 3 minutes, and sample 3 was formed by ramming method; in the same way, the amount of water added was 6% of the total weight of the formula material, sample 4 was formed by vibration casting method, and its performance index was tested.

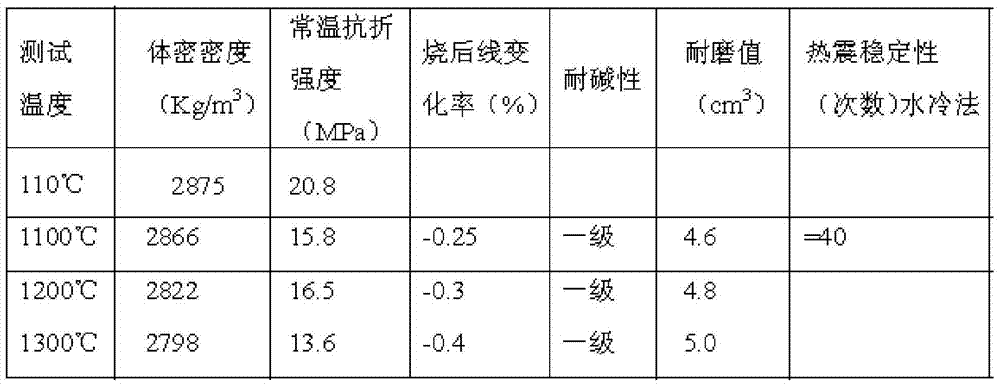

[0035] Table 3 Performance Index of Sample 3

[0036]

[0037] Table 4 Sample 4 Performance Index

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com