Carbon-coated sodium ferric phosphate sodium ion battery positive electrode material, and preparation method and application thereof

A technology of sodium ion battery and sodium iron phosphate, which is applied in the field of electrochemistry, can solve the problems of restricting industrial application and inability to meet large-scale energy storage, and achieve easy industrial control, excellent charge and discharge cycle stability, and meet application requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a method for preparing the positive electrode material of the above-mentioned carbon-coated sodium iron phosphate sodium ion battery, comprising the following steps:

[0057] A) Dissolving the carbon source compound in a mixed solution of methanol and N,N-dimethylformamide, then dissolving the phosphorus-containing sodium source compound, iron source compound and chelating agent in the mixed solution, stirring evenly, Obtain precursor solution;

[0058] B) After putting the precursor solution into an oven for drying, a gel precursor is obtained;

[0059] C) The gel precursor is sequentially calcined for the first time and calcined for the second time to obtain a carbon-coated iron-sodium-sodium-ion battery cathode material.

[0060] Preferably in the present invention, in the mixed solution of methanol and N,N-dimethylformamide, the volume ratio of methanol and N,N-dimethylformamide is 2:1, preferably 20mL methanol+10mL N, N-Dimethy...

Embodiment 1

[0095] In this embodiment, the carbon source compound is polyvinylpyrrolidone, the iron source compound is ferric nitrate, the phosphorus-containing sodium source compound is sodium dihydrogen phosphate, and the chelating agent is citric acid.

[0096] Step 1, carbon-coated sodium iron phosphate (NaFePO 4 / C) materials, the raw materials include ferric nitrate, sodium dihydrogen phosphate, polyvinylpyrrolidone and citric acid, and the solvents are methanol and N,N-dimethylformamide.

[0097] At room temperature, dissolve 1.8g of polyvinylpyrrolidone in a mixed solution of 20mL of methanol and 10mL of N,N-dimethylformamide, then add 6mmol of sodium dihydrogen phosphate, 6mmol of citric acid and 6mmol of ferric nitrate in sequence, and stir The gel precursor solution was uniformly obtained; the gel precursor solution was dried in an oven at 75 °C for 24 h, and then the dried colloid was placed in a tube furnace and heated at a rate of 5 °C / min under a nitrogen atmosphere for 300...

Embodiment 2

[0110] The preparation method is the same as in Example 1, except that the addition of the carbon source compound polyvinylpyrrolidone is changed to 0.9g to obtain the target product NaFePO 4 / C.

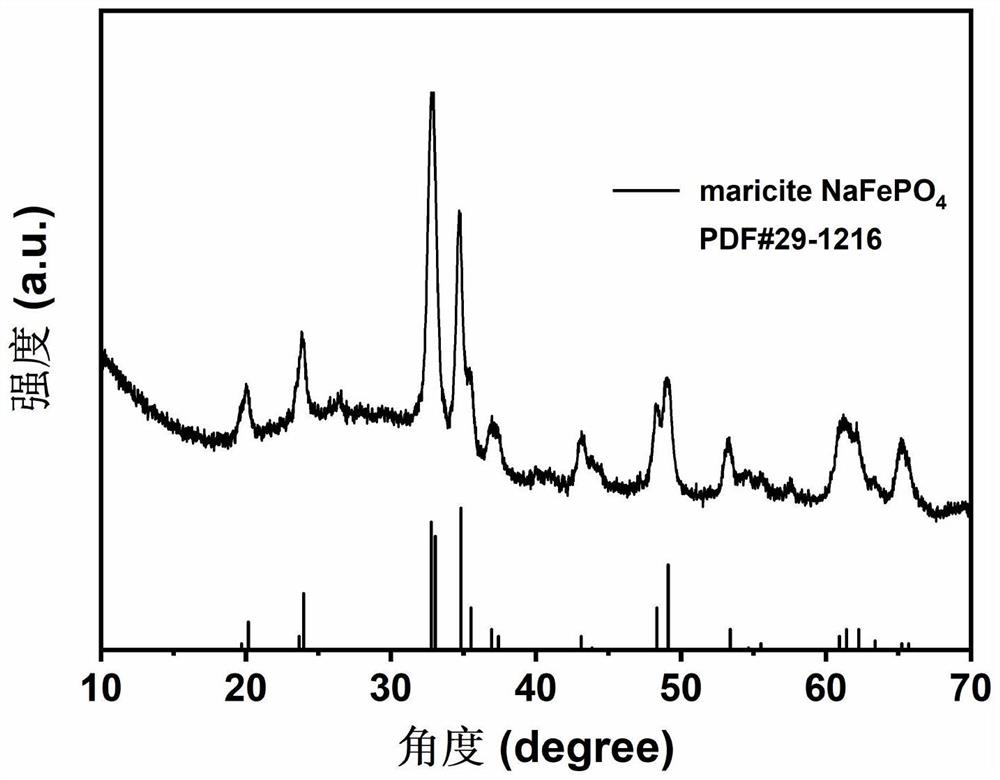

[0111] Figure 8 Shown is the XRD figure and maricite type NaFePO of embodiment 2 gained target product 4 The standard card PDF#29-1216, it can be seen from the figure that the main component of the material is NaFePO 4 , and good crystallinity.

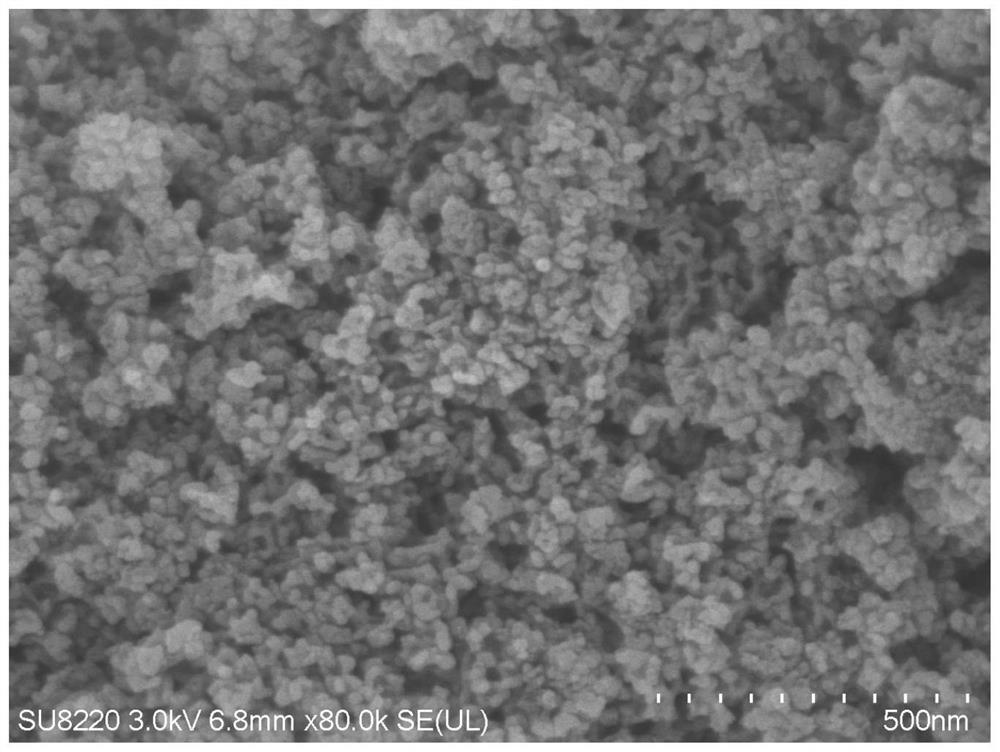

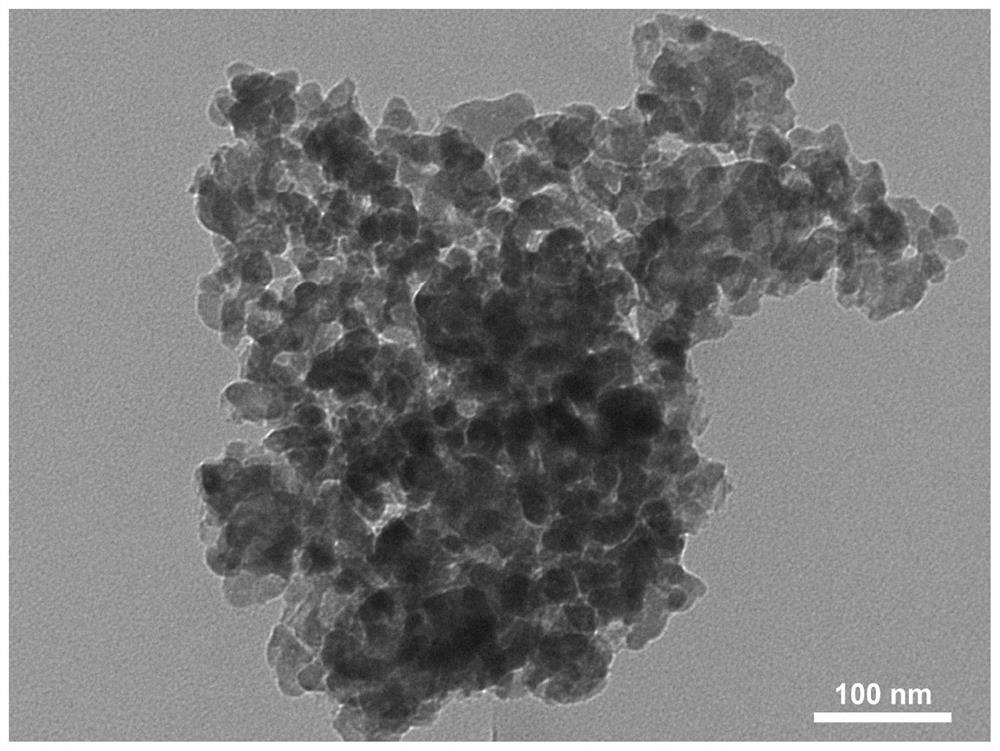

[0112] Figure 9 Shown is the SEM picture of the target product obtained in Example 2, from which it can be seen that the target product is mainly composed of nanoparticles.

[0113] Figure 10 Shown is the obtained target product of embodiment 2 at 20mA g -1 The first charge and discharge curve under the current density, it can be seen from the figure that the material is applied to the sodium ion battery for the first discharge specific capacity to reach 106.6mAh g -1 .

[0114] Figure 11 Shown is the obtained target product of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com