Preparation method of modified sodium alginate-derived carbon negative electrode material with high sodium storage property

A carbon negative electrode material, sodium alginate technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of low sodium storage capacity and achieve high sodium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

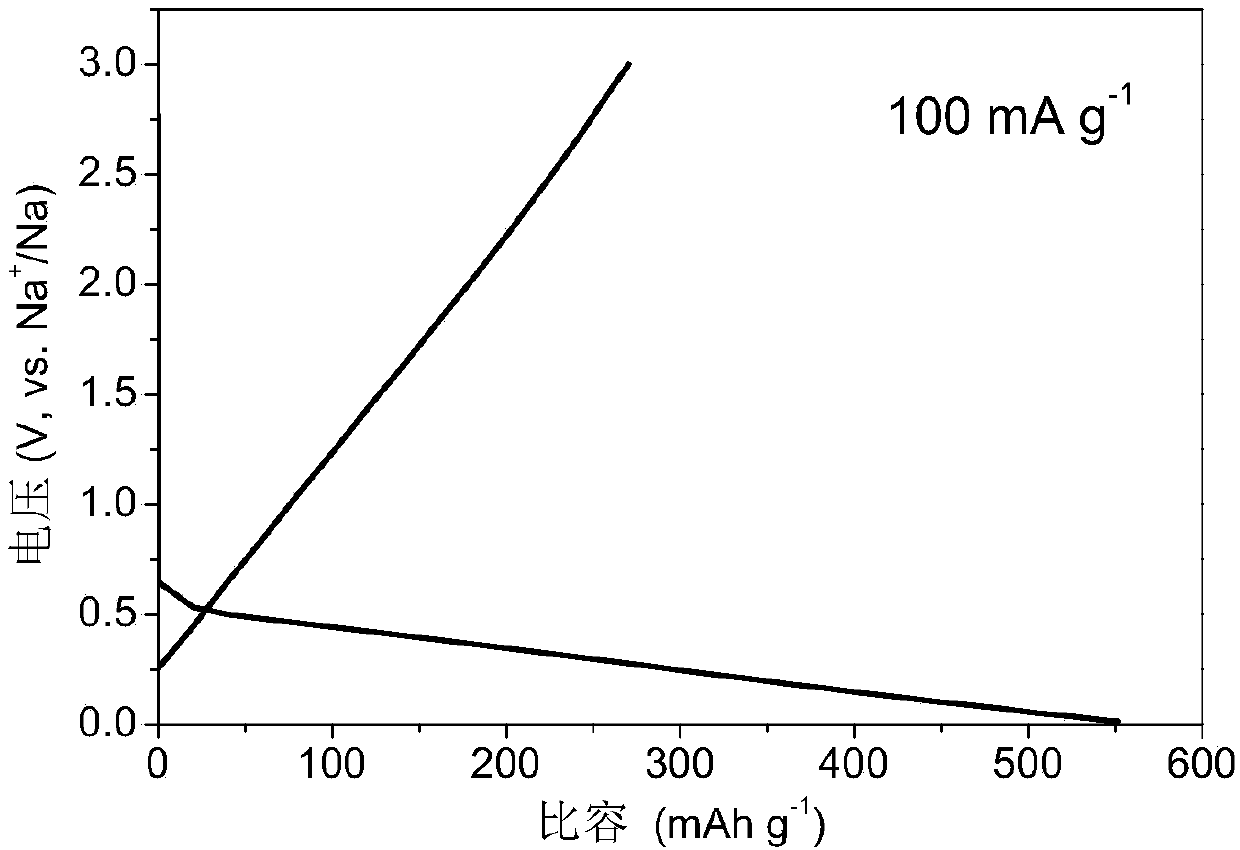

Image

Examples

Embodiment 1

[0025] Put the commercial sodium alginate solid powder into the tube furnace, pass N 2 Protection, and then starting from room temperature, the temperature was raised at a rate of 5°C / min, the temperature was raised to 700°C, and the temperature was kept constant for 2h. Cool to room temperature after carbonization. The above-mentioned intermediate product was soaked in nitric acid with a concentration of 2 mol / L for 12 hours to remove small inorganic molecular compounds produced during the carbon removal process. Then, the above mixed solution was poured into a hydrothermal reaction kettle, and the temperature was raised from room temperature at a rate of 2°C / min to 90°C for hydrothermal oxidation for 3 hours. After filtering, washing with water until neutral, washing with alcohol, and vacuum drying at 50°C for 24 hours, the final product—modified sodium alginate-derived carbon can be obtained.

Embodiment 2

[0027] Put the commercial sodium alginate solid powder into the tube furnace, pass N 2 Protection, and then start from room temperature, raise the temperature at a rate of 5°C / min, raise the temperature to 600°C, and keep the temperature constant for 2h. Cool to room temperature after carbonization. The above-mentioned intermediate product was soaked in nitric acid with a concentration of 2 mol / L for 12 hours to remove small inorganic molecular compounds produced during the carbon removal process. Then, the above mixed solution was poured into a hydrothermal reaction kettle, and the temperature was raised from room temperature at a rate of 2°C / min to 90°C for hydrothermal oxidation for 3 hours. After filtering, washing with water until neutral, washing with alcohol, and vacuum drying at 50°C for 24 hours, the final product—modified sodium alginate-derived carbon can be obtained.

Embodiment 3

[0029] Put the commercial sodium alginate solid powder into the tube furnace, pass N 2 protection, and then start from room temperature, raise the temperature at a rate of 5°C / min, raise the temperature to 800°C, and keep the temperature constant for 2h. Cool to room temperature after carbonization. The above-mentioned intermediate product was soaked in nitric acid with a concentration of 2 mol / L for 12 hours to remove small inorganic molecular compounds produced during the carbon removal process. Then, the above mixed solution was poured into a hydrothermal reaction kettle, and the temperature was raised from room temperature at a rate of 2°C / min to 90°C for hydrothermal oxidation for 3 hours. After filtering, washing with water until neutral, washing with alcohol, and vacuum drying at 50°C for 24 hours, the final product—modified sodium alginate-derived carbon can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com