Heat treatment process for high-strength and high-toughness bainite steel rail welded joint for heavy haul railway

A high-strength and toughness, welded joint technology, applied in the field of rail welding, can solve the problems of many defects in the welding overheating zone, poor matching of the performance of the base metal and the joint, and reduced mechanical properties of the joint, so as to reduce the unstable residual austenite content, improve the Wear and early fatigue fracture, improve the effect of various mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

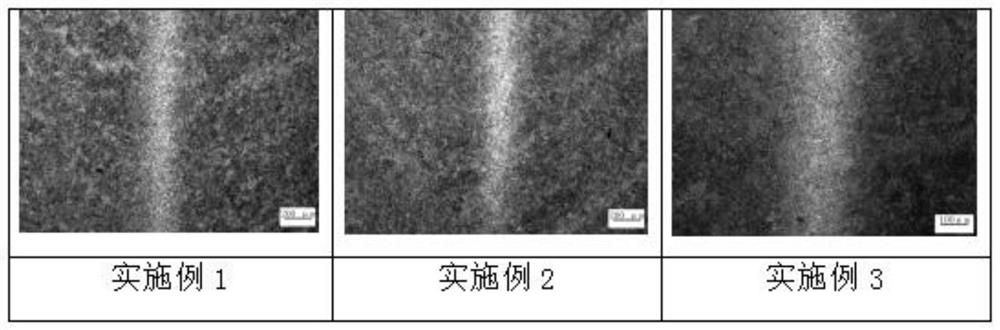

Image

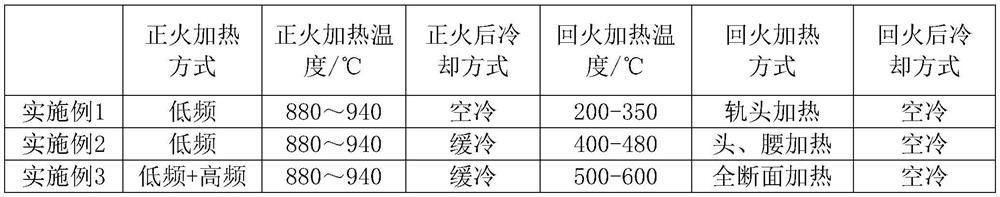

Examples

Embodiment 2

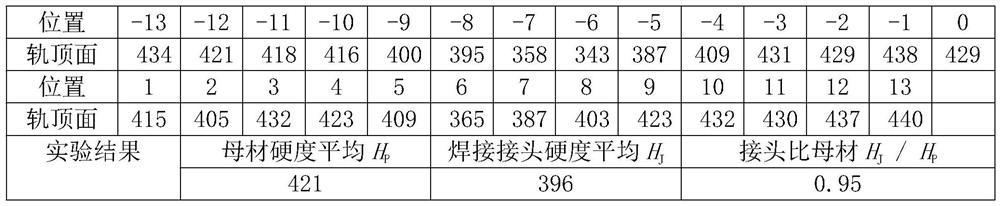

[0043] Table 3 Example 2 joint hardness

[0044]

[0045] Table 4 Example 3 joint hardness

[0046]

[0047] It can be seen from Table 2 to Table 4 that the joint hardness of HJ / HP=0.95 in Example 1 is relatively high to meet the standard requirements, but it is found in the actual use process that the joint hardness is too high under heavy load conditions, and the distance from the rail top tread is about 0- Horizontal cracks are prone to appear at 8mm. In Example 2, the hardness of the joint with HJ / HP=0.85 does not meet the standard requirements, and the joint collapse phenomenon occurs during the service process of the joint. In Example 3, HJ / HP=0.90, and in Example 3, the optimal joint hardness matched with the base metal is obtained, thereby ensuring the excellent service performance of the joint in the application process of heavy-duty railways, and avoiding the rail head that occurs when the joint hardness difference is too small Cracks and joint "saddle-type" ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com