Metal material obtained by method for regulating and controlling crystal face orientation of metal coating and application of metal material

A technology of crystal plane orientation and metal coating, applied in metal material coating process, coating, liquid chemical plating, etc., can solve the problems of uneven reaction and low reactivity, reduce the use of precious metals, and simplify the production process , the effect of large potential value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

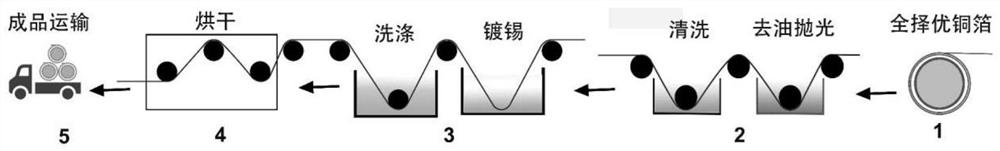

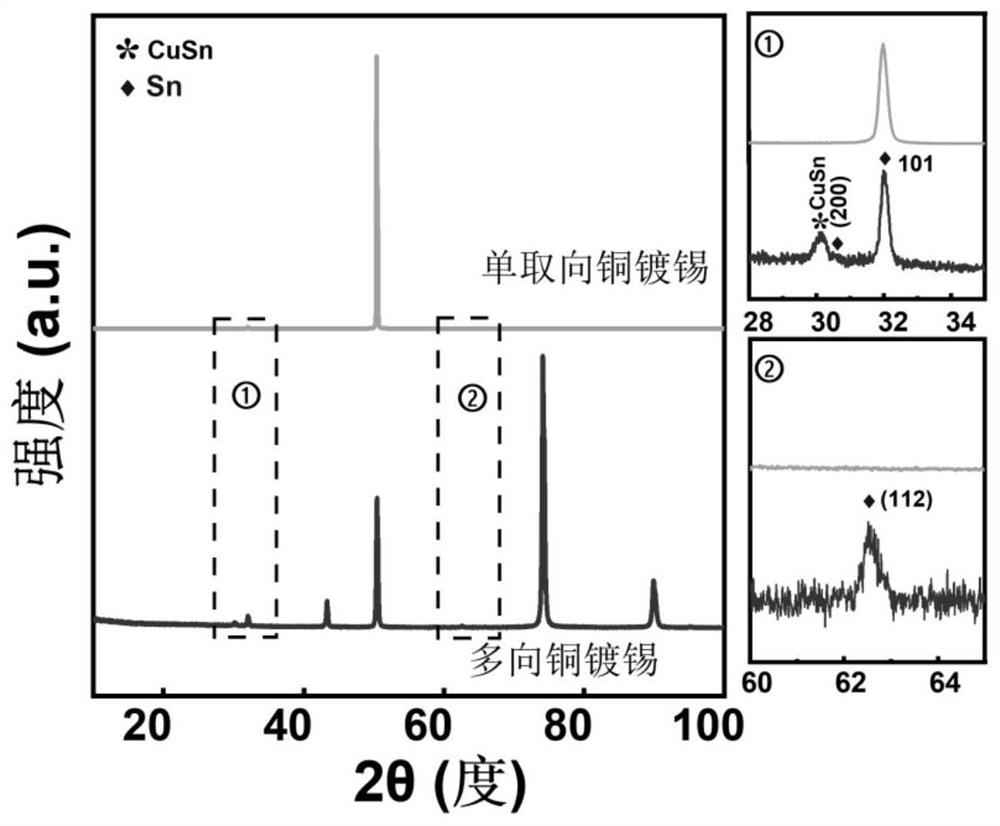

[0048] The commercial 30-micron non-preferential crystal face copper foil and 200-crystal face fully-preferred single crystal face copper foil were soaked in dilute sulfuric acid solution for 2 minutes to remove the surface oil and oxide layer, and then rinsed with deionized water to remove the residual acid solution. Then the copper foil was soaked in NaH 2 PO 2 .2H 2 O(10g L -1 ), CS(NH 2 ) 2 (70g L -1 ), SnCl 2 .H 2 O(10g L -1 ), and HCL (2g L -1 ), the soaking time is 30s and 2min. After soaking, use deionized water to wash off the residual tin plating solution, and dry it in a drying oven at 60°C for 3h to obtain tin metal with a single crystal plane orientation. Coated copper-based material (all-selective copper foil), this preparation process can also be based on the process figure 2 Simple industrial production. The crystallographic structure of the tin coating was then characterized using XRD and backscattered electron diffraction (EBSD). It can be seen f...

Embodiment 2

[0050] The tin-coated copper-based material and commercial copper foil prepared in Example 1 were used as current collectors for aqueous zinc-ion batteries, which were cut to 1 cm 2 The discs were used as electrodes, using 2mol ZnSO 4 As the electrolyte and glass fiber as the separator, a 2025 Zn button half-cell was assembled, and the charge and discharge parameters were set to 5mAcm -2 -2mAhcm -2 (current density and areal capacity), the charge cut-off voltage is 0.5V, and the correlation curve of cycle number and Coulomb efficiency is obtained from Figure 7-8 It was found that the copper current collector material with low zinc affinity (commercial Cu foil without tin plating) was short-circuited in only 41 hours, and even the tin-plated multi-oriented crystal plane copper current collector (multi-oriented Sn) could only Maintaining a normal Coulomb efficiency of 120h, this copper current collector (single-oriented Sn) material with an all-preferential single-crystal pla...

Embodiment 3

[0056] Electroless silver plating was carried out using commercial copper foil (multi-oriented Cu) and Cu(111) with all preferred single crystal plane and Cu(200) with all preferred single crystal plane as substrates, and the silver plating solution was made of AgNO 3 (100gL -1 ), thiourea (1gL -1 ), PVP (0.5gL -1 )HNO 3 (10gL -1 ) composition, first use dilute nitric acid for chemical polishing and degreasing, then use deionized water to wash off residual acid, soak in the plating solution for 2 minutes, take out and wash and dry. XRD was used to characterize the crystal structure of the silver coating. from Figure 13 It is found that the Ag(111) coating with the all-preferred single-crystal plane orientation can be obtained by using Cu(111) with all-preferred single-crystal plane as the substrate.

[0057] To investigate the effect of the silver coating on all-preferential single crystal plane on the hydrogen evolution activity of the electrode, LSV test was also carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com