Cutting fluid for thin-sheet and large-size solar-grade silicon wafer

A solar-grade silicon wafer, thinning technology, applied in lubricating compositions, petroleum industry, etc., can solve the problem that the yield of silicon wafers is difficult to meet the production target demand value of slicing enterprises, the cutting seam is difficult to wet, and the silicon powder is dispersed. Difficulties and other problems, to achieve excellent dynamic and static wetting performance, good wetting efficiency, and reduce the breakage rate of diamond wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

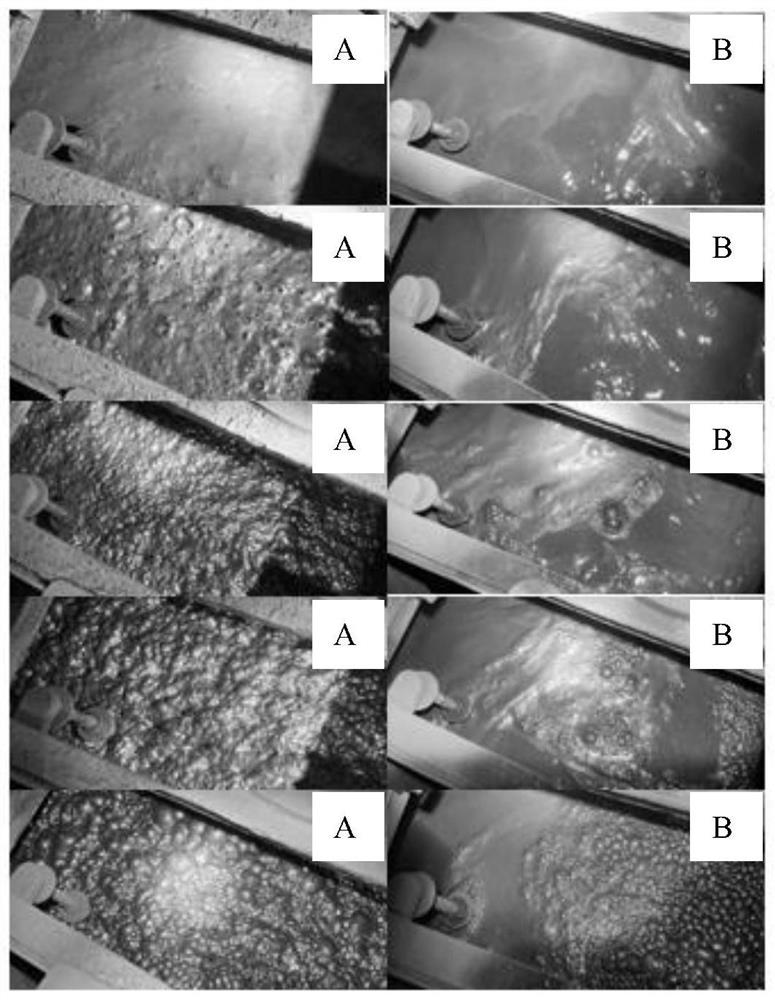

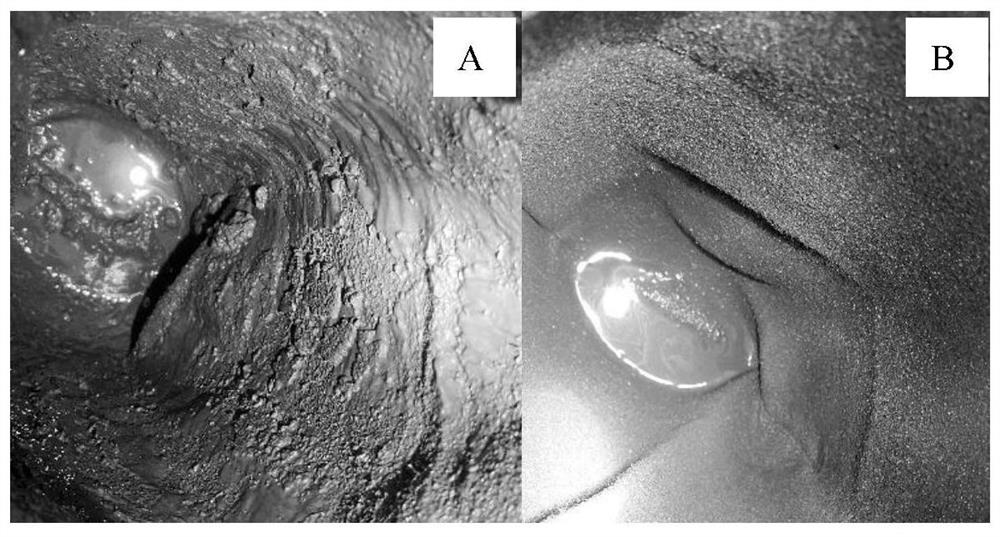

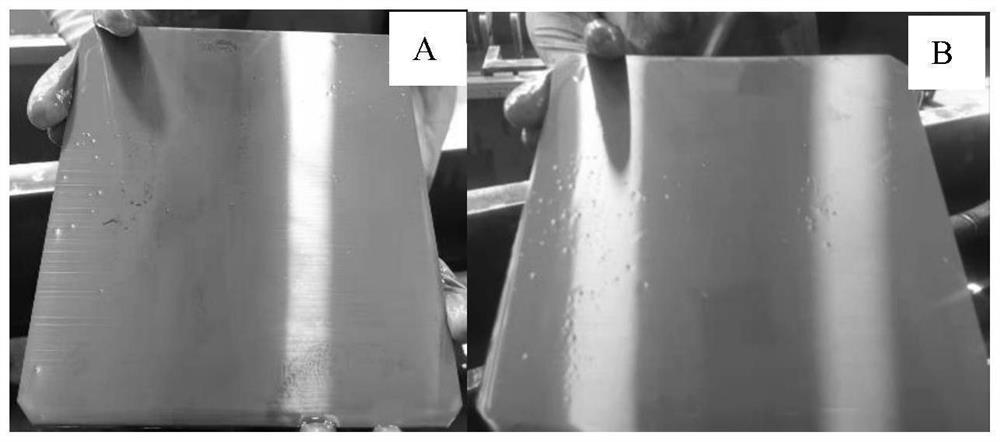

Image

Examples

Embodiment 1

[0037] A cutting fluid for thinning and thinning large-scale solar-grade silicon wafers, comprising the following components in parts by weight:

[0038] Dispersant 30 parts

[0039] Wetting agent 10 parts

[0040] 9 parts of ethylene glycol monohexyl ether

[0041] Pure water balance.

[0042] Wherein, the dispersant is cyclohexyl polyoxyethylene ether whose degree of polymerization n of polyoxyethylene ether is 12. The wetting agent is 2,7-diyne-1,8-octanediol polyoxyethylene polyoxypropylene ether, the polymerization degree m of the polyoxyethylene ether is 7, and the polymerization degree p of the polyoxypropylene ether is 4.

Embodiment 2

[0044] A cutting fluid for thinning and thinning large-scale solar-grade silicon wafers, comprising the following components in parts by weight:

[0045] Dispersant 39 parts

[0046] Wetting agent 14 parts

[0047] 8.5 parts of ethylene glycol monooctyl ether

[0048] Pure water balance.

[0049] Wherein, the dispersant is cyclohexyl polyoxyethylene ether whose degree of polymerization n of polyoxyethylene ether is 16. The wetting agent is 2,7-diyne-1,8-octanediol polyoxyethylene polyoxypropylene ether, the polymerization degree m of the polyoxyethylene ether is 6, and the polymerization degree p of the polyoxypropylene ether is 5.

Embodiment 3

[0051] A cutting fluid for thinning and thinning large-scale solar-grade silicon wafers, comprising the following components in parts by weight:

[0052] Dispersant 32.5 parts

[0053] Wetting agent 10.5 parts

[0054] 10 parts of triethylene glycol monohexyl ether

[0055] Pure water balance.

[0056] Wherein, the dispersant is cyclohexyl polyoxyethylene ether whose degree of polymerization n of polyoxyethylene ether is 20. The wetting agent is 2,7-diyne-1,8-octanediol polyoxyethylene polyoxypropylene ether, the polymerization degree m of the polyoxyethylene ether is 5, and the polymerization degree p of the polyoxypropylene ether is 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com