Gas drainage high-impact PVC (polyvinyl chloride) pipe for coal mine and preparation method thereof

A PVC pipe, high impact technology, used in chemical instruments and methods, pipes, rigid pipes, etc., can solve the problems of poor physical and mechanical properties of pipes, low surface finish of pipes, high processing and extrusion current, and improve processing fluidity. , Improve the dispersion effect, improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

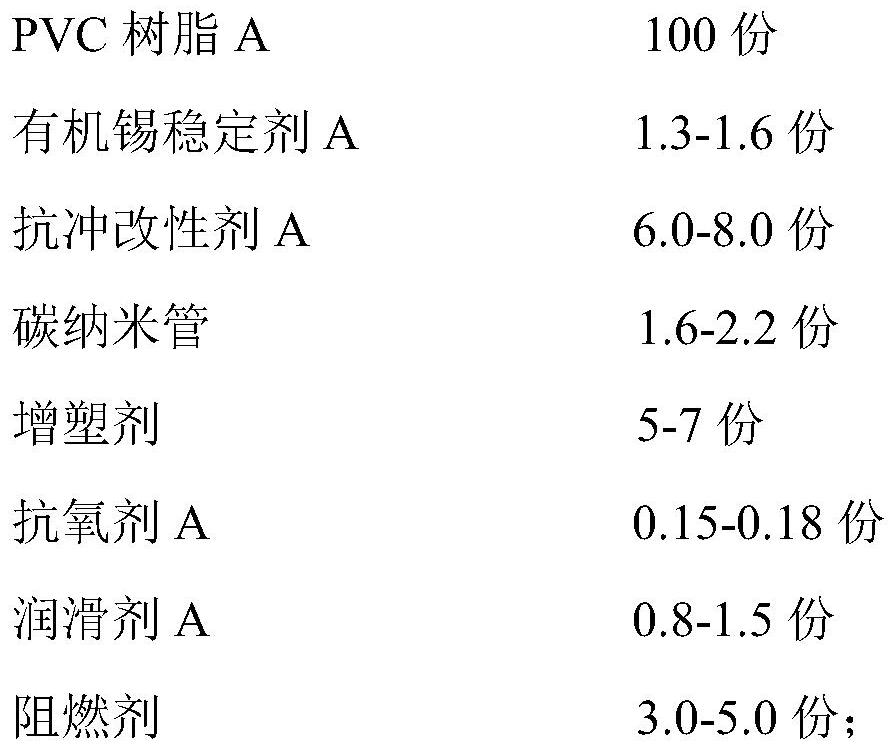

Embodiment 1-5

[0045] Examples 1-5 are the inner and outer antistatic skin layers of high-impact PVC pipes for drainage of gas in coal mines, and the formulations of each example are shown in Table 1.

[0046]The inner and outer cortex formulations of table 1 embodiment 1-5 (by weight)

[0047] raw material Example 1 Example 2 Example 3 Example 4 Example 5 S-700 100 100 100 100 100 TM-181 1.4 1.5 1.5 1.6 1.6 CPE 6 6 7 7 8 MWNT-10 1.8 1.8 1.8 1.8 1.8 top M 5 5 6 6 7 316A 0.3 0.4 0.4 0.5 0.5 PTES 0.6 0.6 0.7 0.7 0.8 1,1'-Thiobis(2-naphthol) 0.1 0.1 0.1 0.11 0.12 triisodecyl phosphite 0.05 0.05 0.05 0.06 0.06 Sb 2 o 3

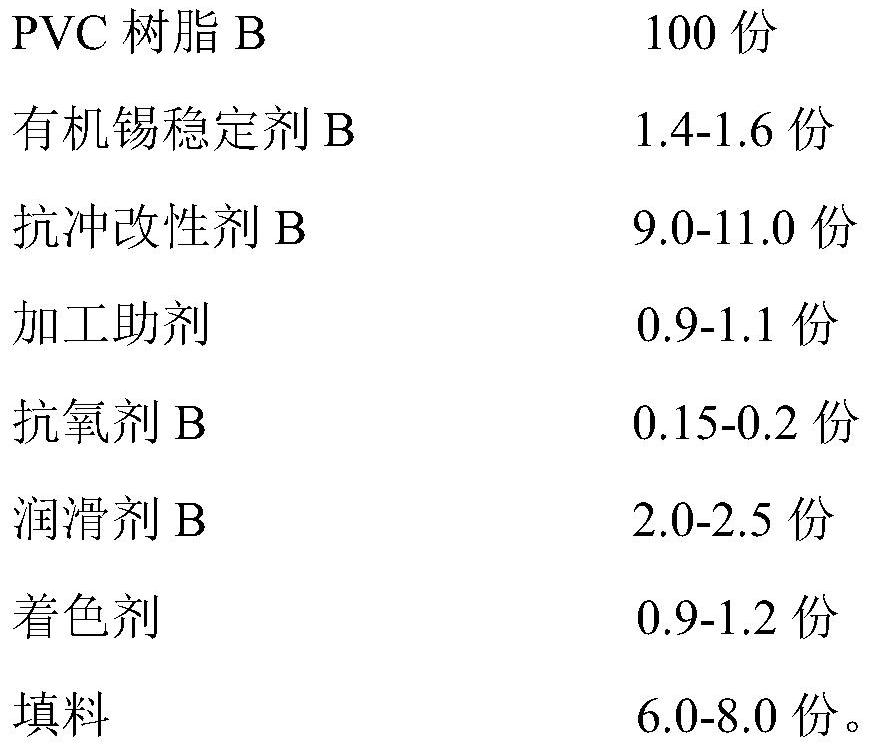

Embodiment 6-10

[0060] Examples 6-10 are core layers of high-impact PVC pipes for gas drainage in coal mines, and the formulations of each example are shown in Table 4.

[0061] The core layer formulation (by weight) of table 4 embodiment 6-10

[0062]

[0063]

Embodiment 6

[0064] In embodiment 6, the core layer butadiene-styrene polymer of the impact modifier MBS, wherein the butadiene content is 36wt%, and the mass ratio of the shell layer ethyl methacrylate to butyl methacrylate is 2.2 : 2.8; The core layer butadiene-styrene polymer of impact modifier MBS in embodiment 7,8, wherein butadiene content is 37.5wt%, shell ethyl methacrylate and butyl methacrylate The mass ratio of is 2:3; The core layer butadiene-styrene polymer of impact modifier MBS among the embodiment 9,10, wherein butadiene content is 38wt%, shell ethyl methacrylate and formaldehyde The mass ratio of butyl acrylate is 1.8:3.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com