Heat-conducting polymer composite material and preparation method thereof

A technology of composite materials and polymers, which is applied in the field of thermally conductive polymer composite materials and their preparation, and can solve problems affecting the performance of thermally conductive potting adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

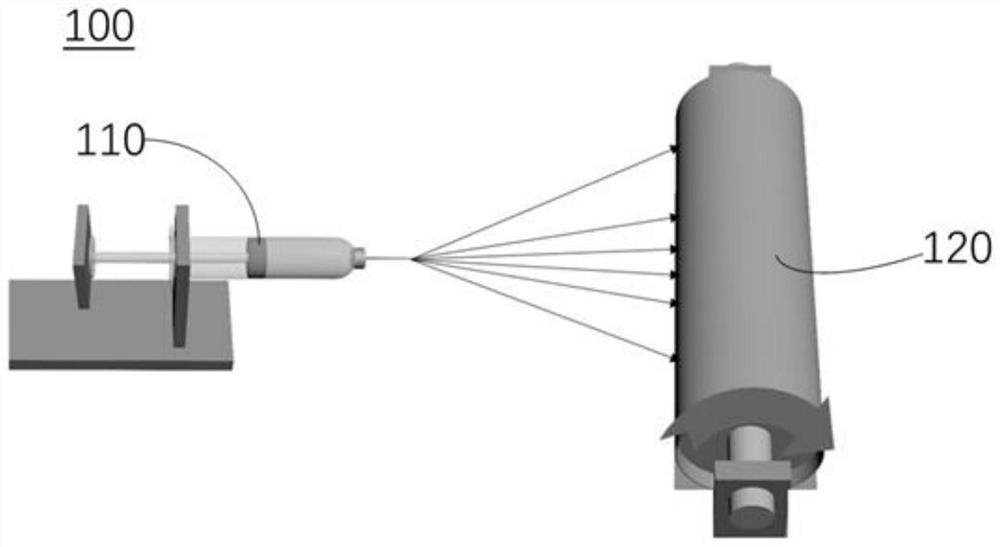

[0045] One embodiment of the present invention provides a method for preparing a thermally conductive polymer composite material, which includes the following steps S10 to S20.

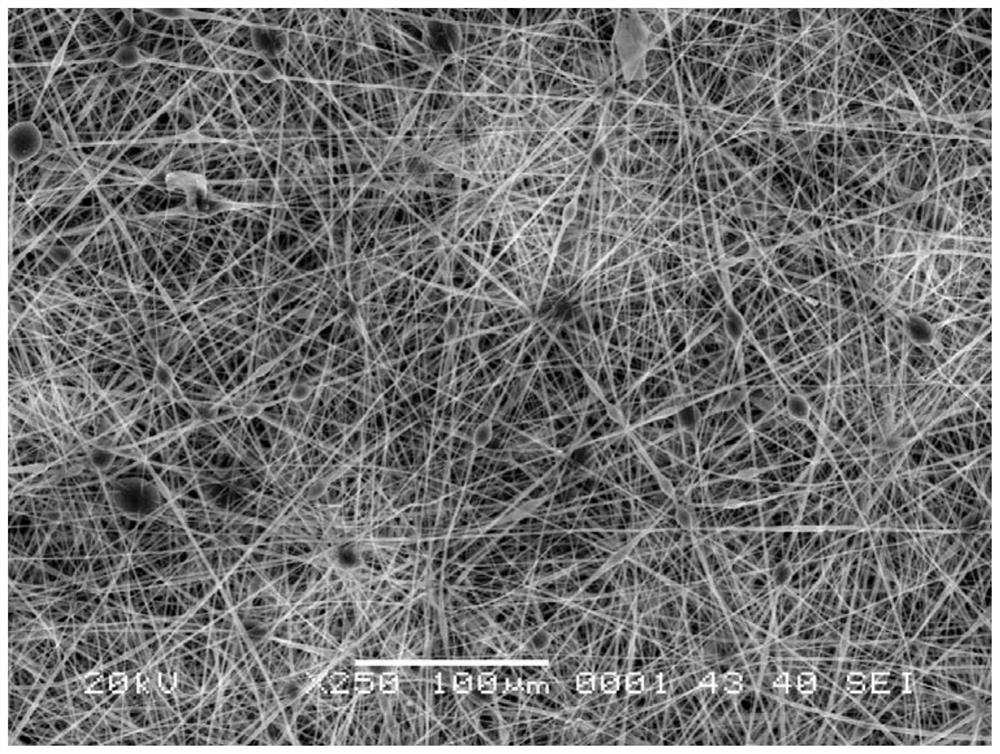

[0046] Step S10: Mix the inorganic filler modified by the coupling agent and the boron nitride nanosheets in a solvent, disperse evenly, add nanofibers, disperse evenly, add an adhesive and an initiator, mix evenly, and form a mixed solution.

[0047]After mixing the inorganic filler modified by the coupling agent and the boron nitride nanosheet, the boron nitride nanosheet has a multi-layer laminated structure, and the inorganic filler modified by the coupling agent will be anchored on the surface of the boron nitride nanosheet. Can effectively enhance the heat transfer path. In a specific example, the inorganic filler modified by the coupling agent and the boron nitride nanosheets are mixed in a solvent, and the dispersion method is ultrasonic. Further, the time of ultrasound is 12h-72h.

[0048] ...

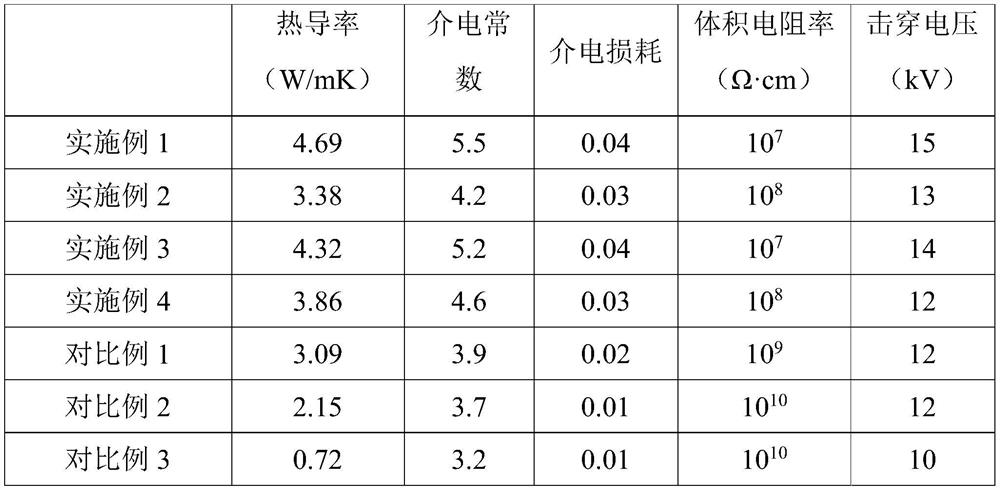

Embodiment 1

[0099] 1. Preparation of inorganic filler modified by coupling agent:

[0100] Select Al with a particle size of 30nm 2 o 3 As the inorganic filler, the silane coupling agent KH-560 is used as the coupling agent. Mix the inorganic filler and the coupling agent in deionized water. The mass ratio of the inorganic filler to the coupling agent is 3:10. Ultrasound for 8 hours, wash and dry to obtain Inorganic filler modified by coupling agent.

[0101] 2. Preparation of boron nitride nanosheets:

[0102] Mix hexagonal boron nitride and glucose with a mass ratio of 1:5 in water, put them into a ball mill, use zirconium beads with a diameter of 0.5mm as the ball milling medium, mill for 24 hours, and the ball milling speed is 1500rpm, wash and dry to obtain boron nitride Nanosheets.

[0103] 3. Preparation of thermally conductive polymer composite materials:

[0104] Add the inorganic filler modified by the coupling agent obtained in step 1 and the boron nitride nanosheets obtai...

Embodiment 2

[0107] 1. Preparation of inorganic filler modified by coupling agent:

[0108] Select Al with a particle size of 30nm 2 o 3 As the inorganic filler, the silane coupling agent KH-560 is used as the coupling agent. Mix the inorganic filler and the coupling agent in deionized water. The mass ratio of the inorganic filler to the coupling agent is 3:10. Ultrasound for 8 hours, wash and dry to obtain Inorganic filler modified by coupling agent.

[0109] 2. Preparation of boron nitride nanosheets:

[0110] Mix hexagonal boron nitride and glucose with a mass ratio of 1:5 in water, put them into a ball mill, use zirconium beads with a diameter of 0.5mm as the ball milling medium, mill for 24 hours, and the ball milling speed is 1500rpm, wash and dry to obtain boron nitride Nanosheets.

[0111] 3. Preparation of thermally conductive polymer composite materials:

[0112] Add the inorganic filler modified by the coupling agent obtained in step 1 and the boron nitride nanosheets obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com