High-solid epoxy coating as well as preparation method and application thereof

An epoxy, high-solid technology, applied in the field of coatings, can solve problems such as viscosity or curing speed that is not suitable for automotive coating processes, and achieve the effects of meeting the requirements of spraying processes, low VOC content, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

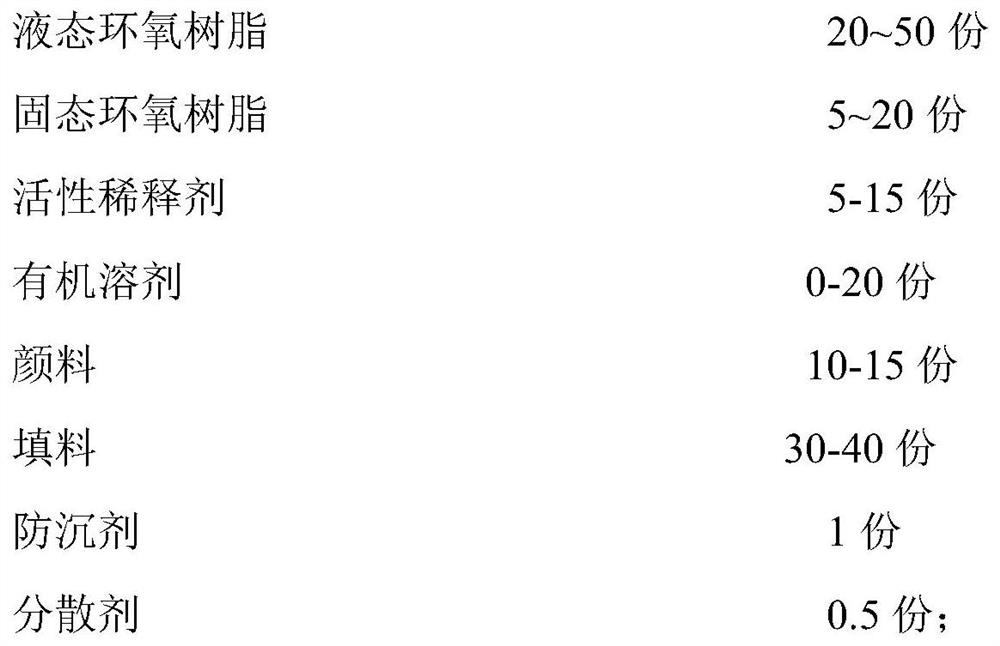

Method used

Image

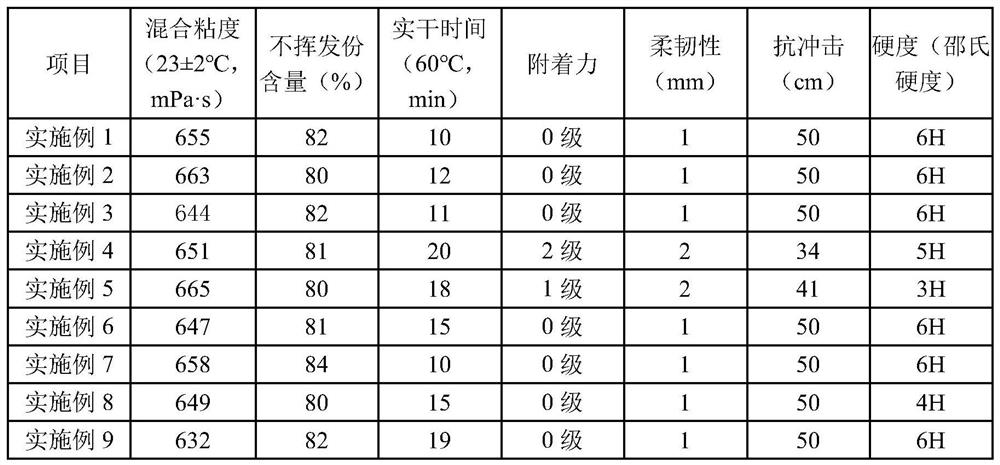

Examples

Embodiment 1

[0076] 1. 10.5 parts of propylene glycol methyl ether, 4.5 parts of butanol, 16 parts of solid bisphenol A epoxy resin 0191, 1.6 parts of Nantong Xingchen Synthetic Materials Co., Ltd. model is the monofunctional reactive diluent of 3630, 6.4 parts of Nantong Xingchen Synthetic Materials Co., Ltd. model is 3622 multifunctional reactive diluent, 1 part of bentonite, 0.5 part of BASF Performance Chemicals (Nanjing) Co., Ltd., and this type of polyurethane dispersant with model EFKA4010 is added to the batching container, heated to 90 ° C, and Stir at a high speed of 1200r / min for 3 minutes until the mixture is uniform, cool down to 60°C, then add 24 parts of liquid bisphenol A epoxy resin of model 0164 from Nantong Xingchen Synthetic Materials Co., Ltd., 10 parts of Shanghai Eve Industrial Co., Ltd. Co., Ltd. titanium dioxide, 40 parts from Shandong Yilite Chemical Co., Ltd., the specification is 500 mesh BaSO 4 , keep stirring at a high speed until the mixture is uniform, lower...

Embodiment 2

[0080] All the other are identical with embodiment 1, and difference is that curing accelerator is made of 1.5 parts of U.S. gas chemical products company, and model is K54 was compounded with 0.3 part of 2,3-bisphosphoglyceric acid purchased from Wuhan Boshikang Bioengineering Co., Ltd.

Embodiment 3

[0082] All the other are identical with embodiment 1, and difference is that curing accelerator is made of 1.125 parts of U.S. gas chemical products company, and model is K54 was compounded with 0.675 parts of 2,3-bisphosphoglyceric acid purchased from Wuhan Boshikang Bioengineering Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com