Fiber continuous forming process based on composite chain preparation

A molding process and fiber technology, which is applied in the field of fiber processing, can solve the problems of single glass fiber components, weak mechanical properties and corrosion resistance of glass fibers, lack of reinforcing materials, etc., and achieve good mechanical properties, small linear shrinkage, and good Effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

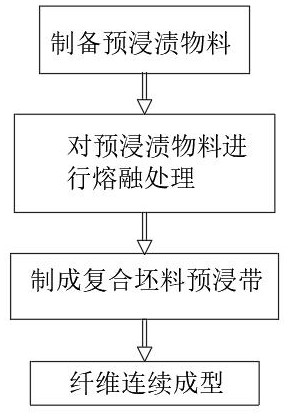

[0031] A fiber continuous molding process based on the preparation of composite chains described in this embodiment includes the following steps, which are specifically described as follows,

[0032] S1. Weaving glass fibers, carbon fibers, and polyurethane resin fibers in bundles to make pre-impregnated materials;

[0033] S2. Perform melting treatment on the pre-impregnated material, and carry out melt impregnation; uniformly mix the dried components according to the proportion, and put them into the pre-mixing device for high-temperature melting;

[0034] S3. Rolling the prepreg material in the molten state to make a composite billet prepreg tape; the melting temperature is 220°C to 250°C; when rolling, it is necessary to apply pressure to the composite billet prepreg tape , the applied pressure is 3 to 4 atmospheres; by applying pressure under the condition of multiple atmospheres, the effect of rolling is better;

[0035] S4. With the cooperation of the traction device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com