Double-sided grinding machine for producing lithium tantalate

A technology of double-sided grinding and lithium tantalate, which is applied in the direction of grinding machine tools, grinding racks, grinding tools, etc., can solve the problems of excessive consumption of grinding tools, harm, and influence on the next grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

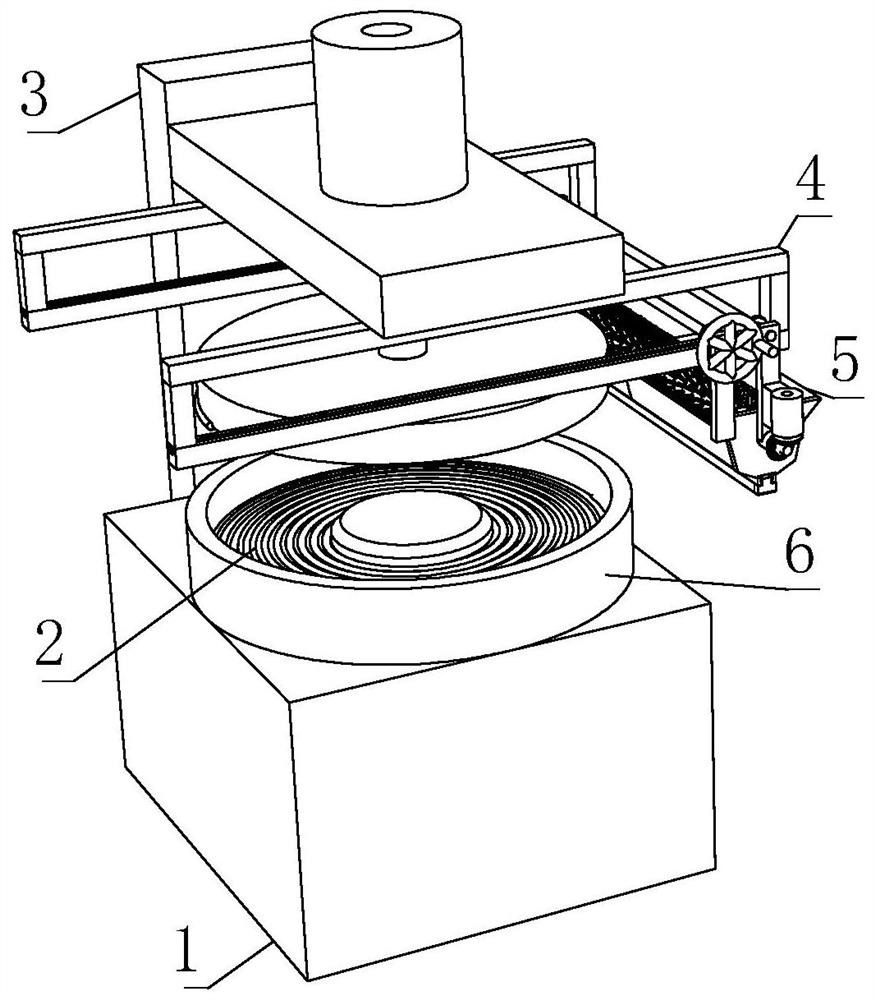

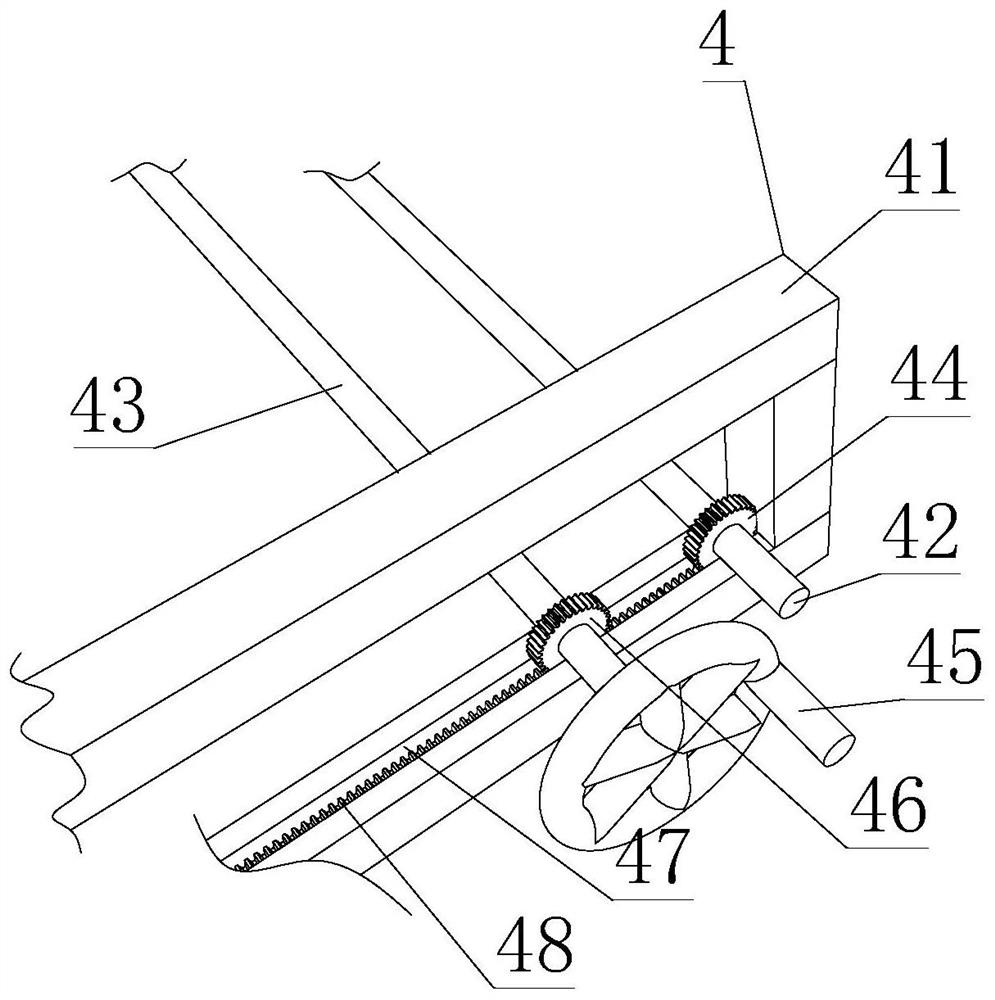

[0036] Such as Figure 1-6 As shown, the present invention provides a double-sided grinding machine for producing lithium tantalate, comprising a base 1, a grinding chamber 6 is fixedly connected to the upper side of the base 1, and a grinding mechanism 2 is fixedly connected to the inside of the grinding chamber 6, and the grinding mechanism 2 Comprising an upper grinding block 21, the upper grinding block 21 includes a positive spiral glass steel ring 217, the upper side of the grinding mechanism 2 is fixedly connected with a support frame 3, and the lower side of the support frame 3 is fixedly connected with a movable frame mechanism 4, and the movable frame mechanism 4 includes a movable Frame 41, the inside of movable frame 41 is provided with counterbore groove 47, and the bottom of movable frame mechanism 4 is fixedly connected with cleaning mechanism 5, and cleaning mechanism 5 comprises rotating cleaning brush mechanism 52, and rotating cleaning brush mechanism 52 comp...

Embodiment 2

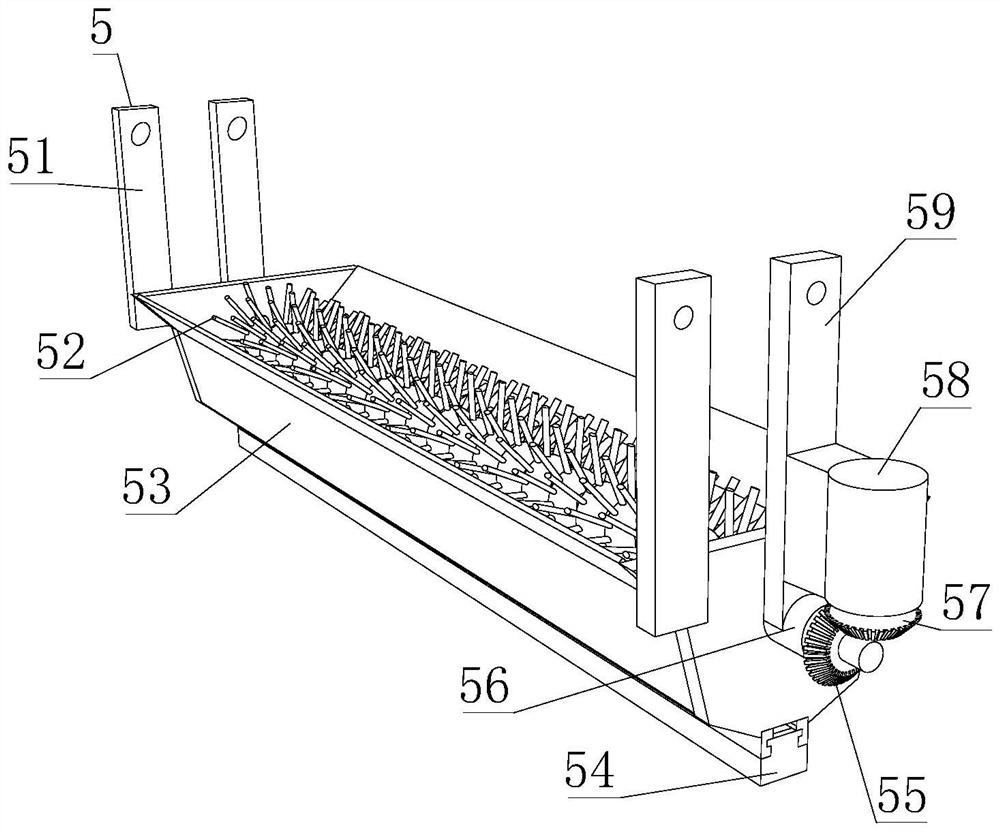

[0039]Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a large rubber ball 5232 is fixedly connected to the upper side of the bristle rod 5235, and the surface of the large rubber ball 5232 is fixedly connected to a rotating rigid bristle 5231, The bottom of the big rubber ball 5232 is fixedly connected with a small rubber ball 5234, and the surface of the small rubber ball 5234 is fixedly connected with a thin bristle 5233. Connected with a spiral brush seat 522, the middle part of the spiral brush seat 522 is fixedly connected with a rotating shaft 521, and the outer side of the bristle mechanism 523 is movably connected with a chip retaining shell 53, and the outer surface of the rotating shaft 521 is rotationally connected with the interior of the chip retaining shell 53. One side of the chip shell 53 is fixedly connected with a connecting shaft sleeve 56, the inner wall of the connecting shaft sle...

Embodiment 3

[0042] Such as Figure 1-6 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the upper side of the positive spiral FRP ring 217 is fixedly connected with FRP 215, and the inner side of FRP 215 is fixedly connected with steel aluminum alloy 216, steel aluminum The outer side of alloy 216 is fixedly connected with manganese brass 212; The upper side of the FRP 215 is fixedly connected, the inner side of the chromium-containing steel 214 is fixedly connected with the outer side of the manganese brass 212, the upper side of the FRP 215 is fixedly connected with the lower side of the manganese brass 212, and the upper side of the manganese brass 212 is fixedly connected with Carbon steel 211, the lower side of the positive spiral glass steel ring 217 is lapped with a lower grinding block 22, the lower grinding block 22 includes a reverse spiral glass steel ring 221, and the outer surface of the forward spiral glass steel ring 217 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com